Harmless treatment method for crystallized waste salt of coal chemical industry

A technology of harmless treatment and coal chemical industry, which is applied in the direction of solid waste removal, etc., can solve the problems of low treatment efficiency of salt washing method, large landfill method, low treatment efficiency, etc. The effect of shortening the time and speeding up the drying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

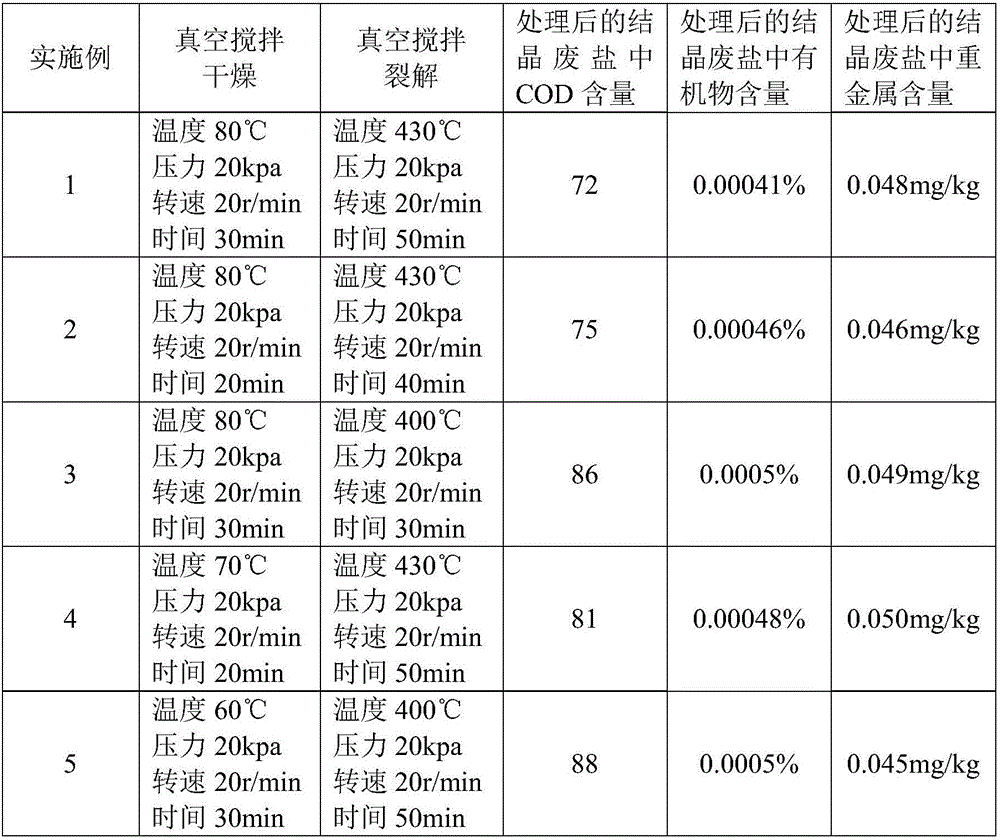

Embodiment 1

[0029] Embodiment 1: Get 500g of crystalline waste salt from the circulating water system of a coal chemical enterprise and the reclaimed water system of a sewage treatment station (configure 20% aqueous solution, and the COD in the detection solution is 5800mg / L), and carry out batching preparation such as batching and coarse crushing Treatment to form granular substances; then preliminary drying treatment, the crystallized waste salt is placed in the drying yard for preliminary drying, the moisture content of the treated crystallized waste salt is <60%; the preliminary dried crystallized waste salt is placed in a vacuum stirring device In the process, dry for 30 minutes under the conditions of vacuum pressure 20kpa, drying temperature 80°C, and rotation speed 20r / min, and the water content of the treated crystallization waste salt is less than 20%; raise the temperature of the vacuum stirring device to 430°C, and maintain a vacuum pressure of 20kpa , the rotation speed is 20r...

Embodiment 2

[0030] Embodiment 2: Get 500g of crystalline waste salt from the circulating water system of a coal chemical enterprise and the reclaimed water system of a sewage treatment station (a 20% aqueous solution is configured, and the COD in the detection solution is 5800mg / L), and the batching preparation such as batching and coarse crushing is carried out. Treatment to form granular substances; then preliminary drying treatment, the crystallized waste salt is placed in the drying yard for preliminary drying, the moisture content of the treated crystallized waste salt is <60%; the preliminary dried crystallized waste salt is placed in a vacuum stirring device In the process, dry for 20 minutes under the conditions of vacuum pressure 20kpa, drying temperature 80°C, and rotation speed 20r / min, and the water content of the treated crystallized waste salt is less than 20%; raise the temperature of the vacuum stirring device to 430°C, and maintain a vacuum pressure of 20kpa , the rotation...

Embodiment 3

[0031] Embodiment 3: Get 500g of crystalline waste salt from the circulating water system of a coal chemical enterprise and the reclaimed water system of a sewage treatment station (a 20% aqueous solution is configured, and the COD in the detection solution is 5800mg / L), and the batching preparation such as batching and coarse crushing is carried out. Treatment to form granular substances; then preliminary drying treatment, the crystallized waste salt is placed in the drying yard for preliminary drying, the moisture content of the treated crystallized waste salt is <60%; the preliminary dried crystallized waste salt is placed in a vacuum stirring device In the process, dry for 30 minutes under the conditions of vacuum pressure 20kpa, drying temperature 80°C, and rotation speed 20r / min, and the water content of the treated crystallized waste salt is less than 20%; raise the temperature of the vacuum stirring device to 400°C, and maintain a vacuum pressure of 20kpa , the rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com