Method for synthesizing molybdenum disulfide by aid of quantum dots

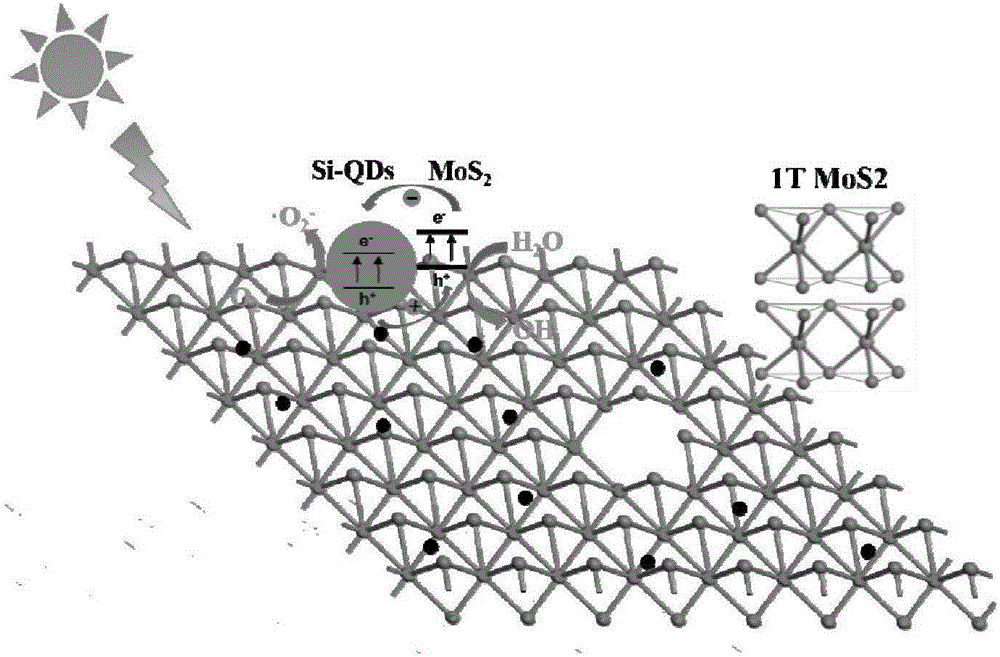

A molybdenum disulfide, quantum dot technology, applied in chemical instruments and methods, chemical/physical processes, special compound water treatment, etc., can solve problems such as environmental damage, human health and even life threats, to improve energy level structure, degradation Effect of rate increase, spectral absorption characteristic change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0018] Specific embodiment one: the method for the synthesis of molybdenum disulfide assisted by quantum dots in this embodiment is carried out according to the following steps:

[0019] 1. Hydrothermal synthesis of silicon quantum dots:

[0020] Dissolve 0.040g-0.060g of sodium ascorbate in 10ml of deionized water and place it for 20 minutes to obtain a mixed solution. Dissolve 1.25ml of the mixed solution in 1ml of trimethoxysilane, add deionized water to make a concentration of 20g / l solution, and pour the solution into a hydrothermal reactor and heat it to 200°C for 24 hours to obtain silicon quantum dots;

[0021] 2. Silicon quantum dots assisted synthesis of molybdenum disulfide:

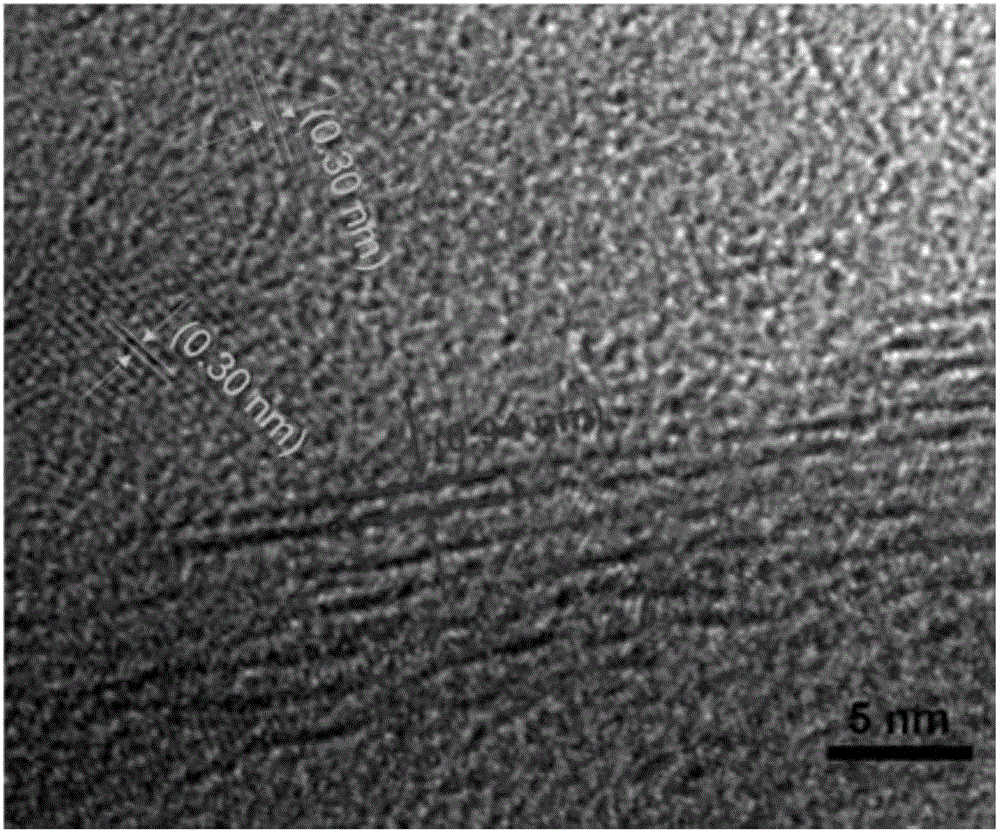

[0022] Dissolve 5mmol-7mmol ammonium molybdate and 17mmol-19mmol thiourea in 20ml deionized water, add 0.025mmol purified silicon quantum dots, then pour the mixed mixture into a hydrothermal reaction kettle, and react at 150°C Cool naturally for 12 hours, collect black deposits, wash with e...

specific Embodiment approach 2

[0023] Embodiment 2: This embodiment differs from Embodiment 1 in that in step 1, 0.0594 g of sodium ascorbate is dissolved in 10 ml of deionized water and left for 20 minutes. Others are the same as the first embodiment.

specific Embodiment approach 3

[0024] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step two, 5 mmol ammonium molybdate and 17 mmol thiourea are dissolved in 20 ml deionized water. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com