Preparation method of ruthenium-molybdenum dioxide nanojunction and use thereof

A molybdenum dioxide, nano-junction technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve problems that hinder large-scale industrial application and cannot meet industrialization needs , the activity and stability are not as good as other problems, to achieve the effect of outstanding catalytic activity and cycle stability, long working time and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

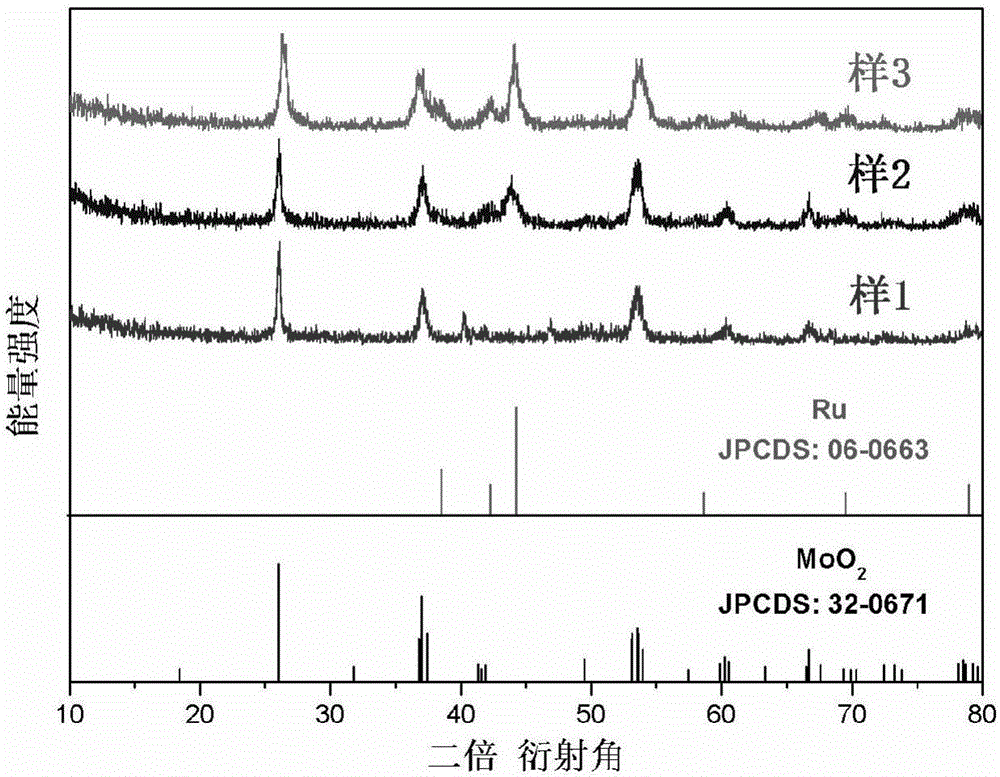

Embodiment 1

[0040] The preparation method of ruthenium-molybdenum dioxide nano junction in this embodiment is as follows:

[0041] 1. Dissolve 2.26 grams of molybdenum hexacarbonyl and 1.5 grams of trimesic acid in 100 milliliters of oxygen-free N,N-dimethylformamide (DMF), then use argon as a protective gas at 156°C for 5 days at reflux, then Cool down to room temperature, centrifuge and vacuum dry to obtain Mo-btc.

[0042] 2. Disperse 50 mg of molybdenum-trimesic acid complex (Mo-btc) particles in 30 mL of absolute ethanol, then add 1.1 mL of RuCl with a concentration of 0.01 g / mL 3 solution, magnetically stirred for 12 hours and then centrifuged and vacuum-dried to obtain the ruthenium-modified Mo-btc precursor;

[0043] 3. Put the ruthenium-modified Mo-btc precursor in a tube furnace, raise the temperature to 700°C at a heating rate of 5°C / min in a nitrogen atmosphere and keep it for 3 hours, then cool to room temperature to obtain molybdenum dioxide-loaded ruthenium Nanojunction (...

Embodiment 2

[0045] The preparation method of ruthenium-molybdenum dioxide nano junction in this embodiment is as follows:

[0046] 1. Dissolve 2.26 grams of molybdenum hexacarbonyl and 1.5 grams of trimesic acid in 100 milliliters of oxygen-free N,N-dimethylformamide (DMF), then use argon as a protective gas at 156°C for 5 days at reflux, then Cool down to room temperature, centrifuge and vacuum dry to obtain Mo-btc.

[0047] 2. Disperse 50 mg of molybdenum-trimesic acid complex (Mo-btc) particles in 30 mL of absolute ethanol, then add 2.2 mL of RuCl with a concentration of 0.01 g / mL 3 solution, magnetically stirred for 12 hours and then centrifuged and vacuum-dried to obtain the ruthenium-modified Mo-btc precursor;

[0048] 3. Put the ruthenium-modified Mo-btc precursor in a tube furnace, raise the temperature to 700°C at a heating rate of 5°C / min in a nitrogen atmosphere and keep it for 3 hours, then cool to room temperature to obtain molybdenum dioxide-loaded ruthenium Nanojunction (...

Embodiment 3

[0050] The preparation method of sample 3 ruthenium-molybdenum dioxide nano junction in the present embodiment is as follows:

[0051] 1. Dissolve 2.26 grams of molybdenum hexacarbonyl and 1.5 grams of trimesic acid in 100 milliliters of oxygen-free N,N-dimethylformamide (DMF), then use argon as a protective gas at 156°C for 5 days at reflux, then Cool down to room temperature, centrifuge and vacuum dry to obtain Mo-btc.

[0052] 2. Disperse 50 mg of molybdenum-trimesic acid complex (Mo-btc) particles in 30 mL of absolute ethanol, then add 4.4 mL of RuCl with a concentration of 0.01 g / mL 3 solution, magnetically stirred for 12 hours and then centrifuged and vacuum-dried to obtain the ruthenium-modified Mo-btc precursor;

[0053] 3. Put the ruthenium-modified Mo-btc precursor in a tube furnace, raise the temperature to 700°C at a heating rate of 5°C / min in a nitrogen atmosphere and keep it for 3 hours, then cool to room temperature to obtain molybdenum dioxide-loaded ruthenium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com