Preparation method of graphene oxide composite nano-filtration membrane

A graphene composite and nanofiltration membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve the effect of simple and easy operation, high water flux and separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

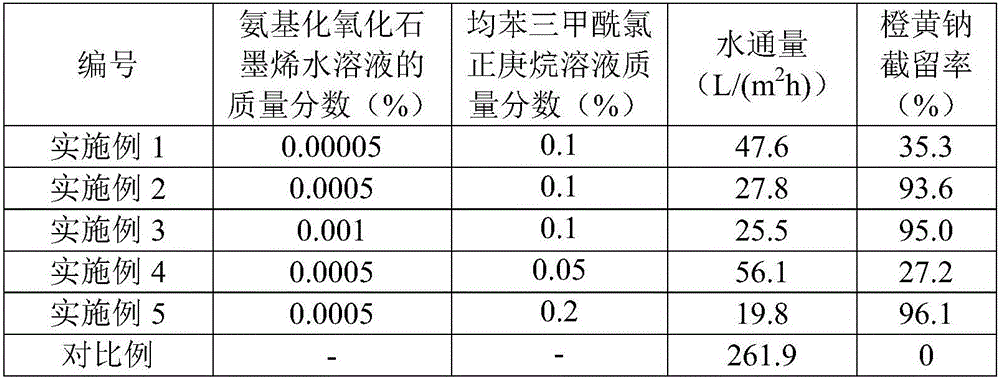

[0017] Embodiment 1, prepare graphene oxide composite nanofiltration membrane, the steps are as follows:

[0018] Step 1. Preparation of polyethersulfone base membrane: dissolve polyethersulfone in N,N-dimethylformamide to prepare a casting solution containing polyethersulfone with a mass concentration of 15-18%, and stir at 60°C 4h, and stand at 60°C for 4h defoaming, after cooling to room temperature, pour the casting solution on a glass plate to scrape the film, put it in a water bath at 25°C to solidify to form a film, remove it from the glass plate and wash it with deionized water Soak for 24 hours to obtain polyethersulfone base membrane;

[0019] Step 2, preparation of aminated graphene oxide: adding sodium hydroxide to the graphene oxide solution with a mass fraction of 0.1% to make the concentration reach 0.04%, and ultrasonically dispersing the mixed solution for 3 hours. Add hydrochloric acid to the above mixed solution until the pH value is neutral, then centrifug...

Embodiment 2

[0022] Embodiment 2, preparation of graphene oxide composite nanofiltration membrane, its preparation process is basically the same as embodiment 1, the only difference is: in step 3, the obtained polyethersulfone base membrane is soaked in the aqueous solution of aminated graphene oxide, its amino The mass fraction of the graphene oxide aqueous solution was changed from 0.00005% to 0.0005%, and finally the graphene oxide composite nanofiltration membrane 2 was obtained.

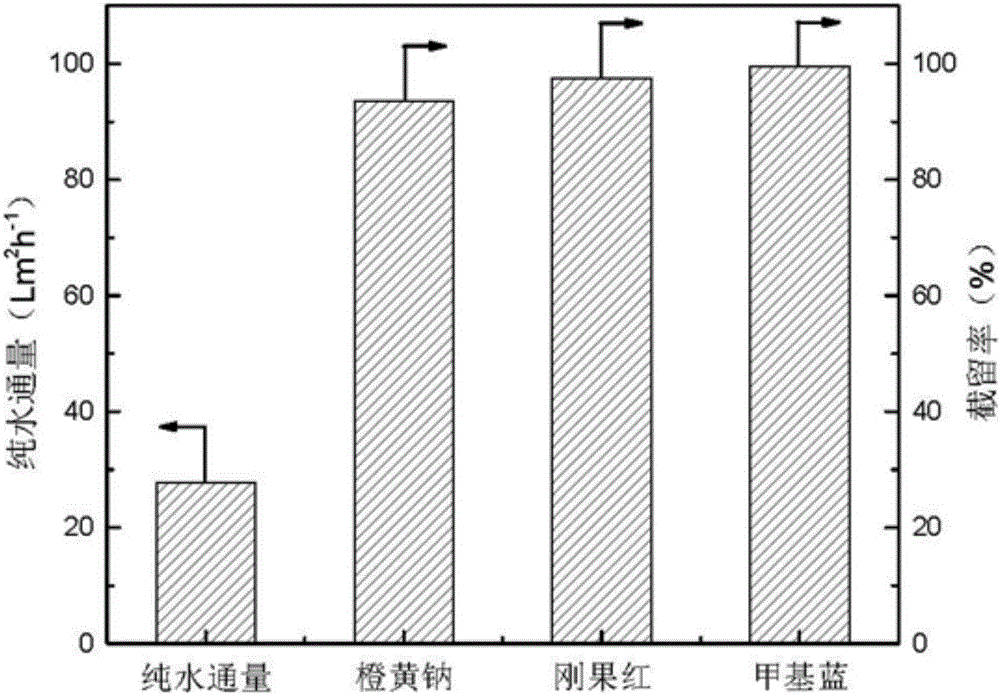

[0023] The water flux of the graphene oxide composite nanofiltration membrane 2 prepared in embodiment 2 under 0.2MPa operating pressure is 27.8L / (m 2 h), the rejection rate of sodium orange (mass fraction 0.01%) aqueous solution is 93.6%. figure 1 It is a diagram of the rejection rate of graphene oxide composite nanofiltration membrane 2 against aqueous solutions of sodium orange, Congo red, and methyl blue (both mass fractions are 0.01%).

Embodiment 3

[0024] Embodiment 3, preparing graphene oxide composite nanofiltration membrane, its preparation process is basically the same as embodiment 1, the only difference is: in step 3, the obtained polyethersulfone base membrane is soaked in the aqueous solution of aminated graphene oxide, and its amino The mass fraction of the graphene oxide aqueous solution was changed from 0.00005% to 0.001%, and finally the graphene oxide composite nanofiltration membrane 3 was obtained.

[0025] The water flux of the graphene oxide composite nanofiltration membrane 3 prepared in embodiment 3 under 0.2MPa operating pressure is 25.5L / (m 2 h), the rejection rate of sodium orange yellow (mass fraction 0.01%) aqueous solution is 95.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com