Luminous nail sticking film and preparation method of luminous nail sticking film

A technology for nail stickers and nails, which is applied in manicure, pedicure, pharmaceutical formulations, etc. It can solve the problems of poor weather resistance and uneven distribution of rare earth zinc sulfide, and achieve the effects of improved compatibility, convenient transportation and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

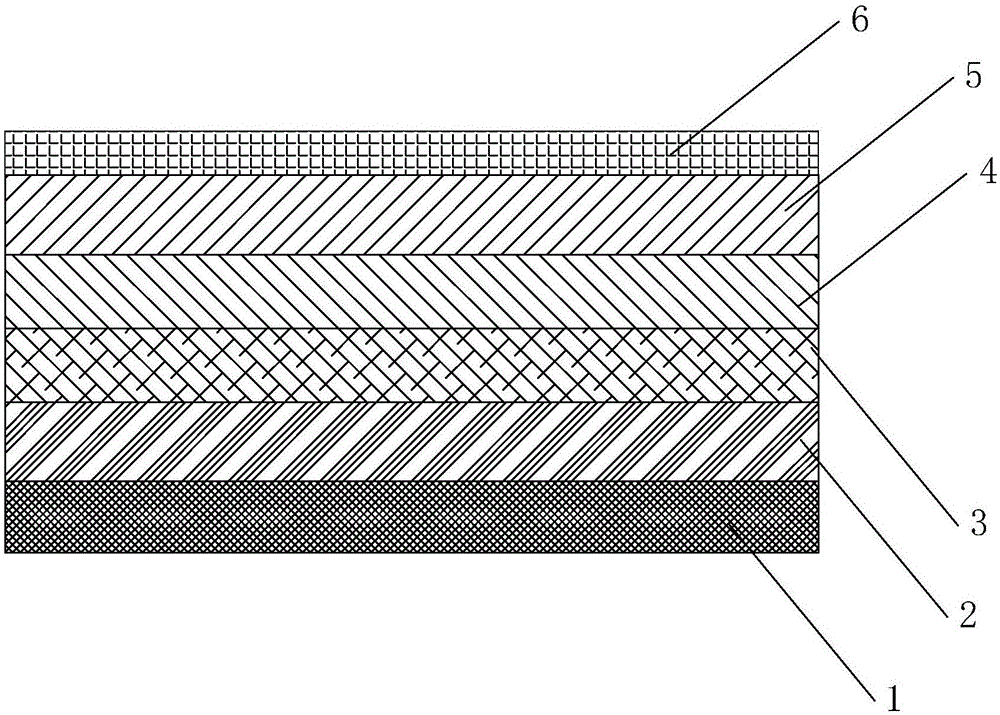

[0031] (1) Add 20g of rare earth zinc sulfide to 100g of γ-aminopropyltriethoxysilane-ethanol solution with a mass concentration of 20%, stir and mix evenly, dry at 80°C for 8 hours, grind through a 60-mesh sieve to obtain 38g Modified rare earth zinc sulfide; 40g butyl acetate, 30g ethyl acetate, 10g nitrocellulose, 20g acrylic polymer, 1g bis(2-ethylhexyl) phthalate, 3g modified rare earth zinc sulfide and 10g pigment Add it into a high-speed mixer and mix it evenly to make a luminous paint;

[0032] (2) Evenly coat a layer of glue layer 2 on the bottom film layer 1 with a thickness of 0.2mm, and then dry it at 50°C for 3 minutes;

[0033] (3) Evenly coat a layer of transparent nail polish on the surface of the glue layer 2 to form an isolation layer 3 with a thickness of 0.1mm, and dry it at 50°C for 5 minutes;

[0034] (4) Evenly coat a layer of luminous paint on the surface of the isolation layer 3 with a thickness of 0.2mm, and dry it at 45°C for 5 minutes;

[0035] (5...

Embodiment 2

[0039] (1) Add 25g of rare earth zinc sulfide to 100g of γ-aminopropyltriethoxysilane-ethanol solution with a mass concentration of 20%, stir and mix evenly, dry at 80°C for 9 hours, grind through a 60-mesh sieve to obtain 42g Modified rare earth zinc sulfide; 35g butyl acetate, 25g ethyl acetate, 15g nitrocellulose, 15g acrylic polymer, 2g bis(2-ethylhexyl) phthalate, 5g modified rare earth zinc sulfide and 8g pigment Add it into a high-speed mixer and mix it evenly to make a luminous paint;

[0040] (2) Evenly coat a layer of glue layer 2 on the bottom film layer 1 with a thickness of 0.1mm, and then dry it at 40°C for 3 minutes;

[0041] (3) Evenly coat a layer of transparent nail polish on the surface of the glue layer 2 to form an isolation layer 3 with a thickness of 0.15mm, and dry it at 60°C for 5 minutes;

[0042] (4) Evenly coat a layer of luminous paint on the surface of the isolation layer 3 with a thickness of 0.1mm, and dry it at 40°C for 5 minutes;

[0043] (5...

Embodiment 3

[0047] (1) Add 22g of rare earth zinc sulfide to 100g of γ-aminopropyltriethoxysilane-ethanol solution with a mass concentration of 20%, stir and mix evenly, dry at 80°C for 10 hours, grind through a 60-mesh sieve to obtain 40g Modified rare earth zinc sulfide; 30g butyl acetate, 35g ethyl acetate, 20g nitrocellulose, 35g acrylic polymer, 3g bis(2-ethylhexyl) phthalate, 6g modified rare earth zinc sulfide and 12g pigment Add it into a high-speed mixer and mix it evenly to make a luminous paint;

[0048] (2) Evenly coat a layer of glue layer 2 on the bottom film layer 1 with a thickness of 0.15mm, and then dry it at 45°C for 3 minutes;

[0049] (3) Evenly coat a layer of transparent nail polish on the surface of the glue layer 2 to form an isolation layer 3 with a thickness of 0.05mm, and dry it at 40°C for 5 minutes;

[0050](4) Evenly coat a layer of luminous paint on the surface of the isolation layer 3 with a thickness of 0.4mm, and dry it at 50°C for 5 minutes;

[0051] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com