A temperature-changing nail film and its preparation method

A nail sticker, temperature change technology, applied in manicure, pedicure, medical formula and other directions, can solve the problems of secondary injury to the human body, long waiting time for drying, human health hazards, etc., and achieves convenient removal, convenient carrying and transportation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Add 30g of polyvinyl alcohol into 100g of water, heat to boiling, stir until completely dissolved, add 8g of red pigment, and spray dry to obtain 38g of temperature-changing pigment microspheres, mix 40g of butyl acetate, 30g of ethyl acetate, 10g of Add nitrocellulose, 20 g of acrylic acid polymer, 2 g of bis(2-ethylhexyl) phthalate, 2 g of salicylic acid and 10 g of temperature-changing pigment microspheres into a high-speed mixer and mix uniformly to prepare 90 g of temperature-changing paint.

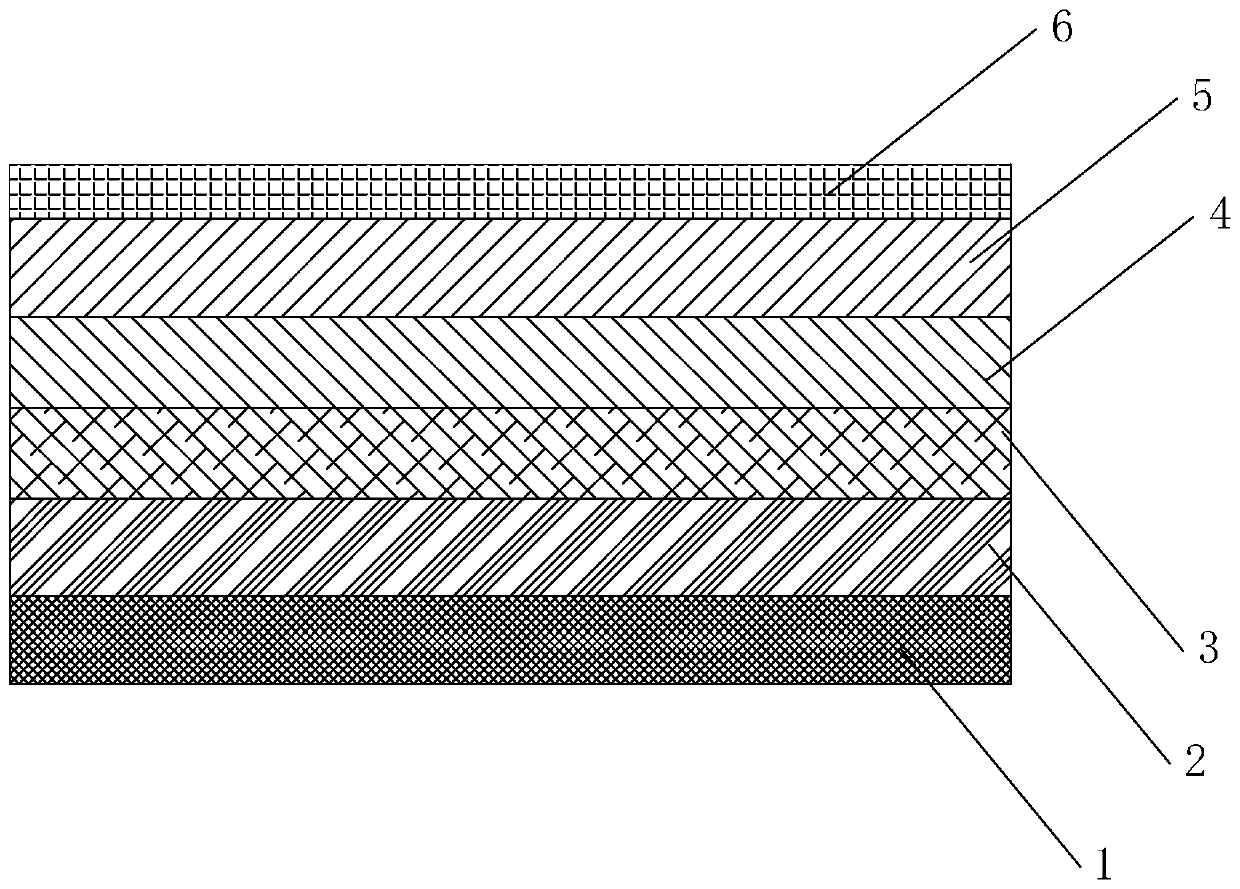

[0032] (2) Evenly coat a layer of glue layer 2 on the bottom film layer 1 with a thickness of 0.2mm, and then dry it at 50°C for 3 minutes;

[0033] (3) Evenly coat a layer of transparent nail polish on the surface of the glue layer 2 to form an isolation layer 3 with a thickness of 0.1mm, and dry it at 50°C for 5 minutes;

[0034] (4) Evenly coat a layer of temperature-changing paint on the surface of the isolation layer 3 with a thickness of 0.2mm, and dry it at 45°C fo...

Embodiment 2

[0039] (1) Add 35g of polyvinyl alcohol into 100g of water, heat to boiling, stir until completely dissolved, add 10g of red pigment, and spray dry to obtain 42g of pigment microspheres, mix 45g of butyl acetate, 40g of ethyl acetate, 15g of nitrocellulose 15g of acrylic acid polymer, 1g of bis(2-ethylhexyl) phthalate, 3g of salicylic acid and 8g of temperature-changing pigment microspheres were added into a high-speed mixer and mixed evenly to prepare a temperature-changing coating.

[0040] (2) Evenly coat a layer of glue layer 2 on the bottom film layer 1 with a thickness of 0.1mm, and then dry it at 40°C for 3 minutes;

[0041] (3) Evenly coat a layer of transparent nail polish on the surface of the glue layer 2 to form an isolation layer 3 with a thickness of 0.15mm, and dry it at 60°C for 5 minutes;

[0042] (4) Evenly coat a layer of temperature-changing paint on the surface of the isolation layer 3 with a thickness of 0.1mm, and dry it at 40°C for 5 minutes;

[0043] ...

Embodiment 3

[0047] (1) Add 40g polyvinyl alcohol into 100g water, heat to boiling, stir until completely dissolved, add 12g red pigment, and spray dry to obtain 48g pigment microspheres, mix 50g butyl acetate, 25g ethyl acetate, 20g nitrocellulose , 35g of acrylic acid polymer, 3g of bis(2-ethylhexyl) phthalate, 4g of salicylic acid and 12g of temperature-changing pigment microspheres were added into a high-speed mixer and mixed uniformly to obtain 90g of temperature-changing paint.

[0048] (2) Evenly coat a layer of glue layer 2 on the bottom film layer 1 with a thickness of 0.15mm, and then dry it at 45°C for 3 minutes;

[0049] (3) Evenly coat a layer of transparent nail polish on the surface of the glue layer 2 to form an isolation layer 3 with a thickness of 0.05mm, and dry it at 40°C for 5 minutes;

[0050] (4) Evenly coat a layer of temperature-changing paint on the surface of the isolation layer 3 with a thickness of 0.4mm, and dry it at 50°C for 5 minutes;

[0051] (5) printing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com