A stem washing method of a temperature gradient type stem washing equipment

A kind of equipment and stem washing technology, which is applied in the field of temperature gradient washing stem washing equipment, can solve the problems of reducing the content of cell wall substances, easily generating burning sensation in smoke, and cumbersome steps, so as to reduce the content of cell wall substances, increase the wall-breaking effect, and reduce moisture content. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

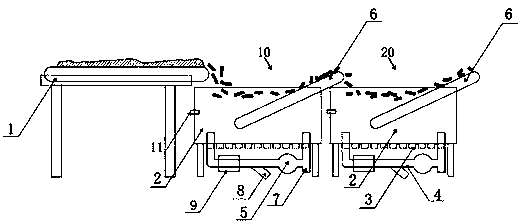

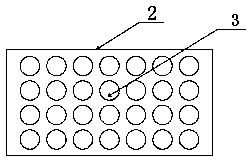

[0034] The stem-washing method of the temperature gradient type stem-washing device adopts the stem-washing device as described above, and the stem-washing device has two sets of washing devices, which are respectively called the first washing device and the second washing device, including the following steps:

[0035]Inject alkaline alcohol solution in the washing tank of the first washing device, inject compound enzyme preparation aqueous solution in the washing tank of the second washing device; Start the circulating water pump and heat exchanger of two sets of washing devices respectively; When the alkaline alcohol solution When the temperature is 65°C and the temperature of the aqueous solution of the compound enzyme preparation is 50°C, start the feeding conveyor belt to feed the tobacco stems, wherein the tobacco stem materials are tobacco stems from different parts, different origins, and different varieties in proportion; Stems are divided into tobacco stem groups A a...

Embodiment 2

[0038] The stem-washing method of the temperature gradient type stem-washing device adopts the stem-washing device as described above, and the stem-washing device has two sets of washing devices, which are respectively called the first washing device and the second washing device, including the following steps:

[0039] Inject alkaline alcohol solution in the washing tank of the first washing device, inject compound enzyme preparation aqueous solution in the washing tank of the second washing device; Start the circulating water pump and heat exchanger of two sets of washing devices respectively; When the alkaline alcohol solution When the temperature is 50°C and the temperature of the aqueous solution of the compound enzyme preparation is 59°C, start the feeding conveyor belt to feed the tobacco stems, wherein the tobacco stem materials are tobacco stems from different parts, different origins, and different varieties in proportion; Stems are divided into tobacco stem groups A ...

Embodiment 3

[0042] The stem-washing method of the temperature gradient type stem-washing device adopts the stem-washing device as described above, and the stem-washing device has two sets of washing devices, which are respectively called the first washing device and the second washing device, including the following steps:

[0043] Inject alkaline alcohol solution in the washing tank of the first washing device, inject compound enzyme preparation aqueous solution in the washing tank of the second washing device; Start the circulating water pump and heat exchanger of two sets of washing devices respectively; When the alkaline alcohol solution When the temperature is 55°C and the temperature of the aqueous solution of the compound enzyme preparation is 55°C, start the feed conveyor belt to feed the tobacco stems, wherein the tobacco stem materials are tobacco stems from different parts, different origins, and different varieties in proportion; The stems are divided into tobacco stem groups A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com