Flue-curing method for fresh tobacco leaves

A curing method and technology for fresh tobacco leaves, which are applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of complicated operation, high machine cost, crushed petiole, etc., and achieve the improvement of curing quality, fast weaving and binding, and simple and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] A method for baking fresh tobacco leaves, comprising the steps of weaving and binding the fresh tobacco leaves and hanging them in a flue-cured tobacco room for baking. The butt joint sides provided on the two racks are docked and several spaced tobacco leaf installation spaces are formed between the two dry racks; so that the ends of the fresh tobacco leaves are tied tightly into the tobacco leaf installation space by the binding wires and are in a suspended state, reducing the amount of tobacco leaves during baking. Contact with the rack improves baking uniformity.

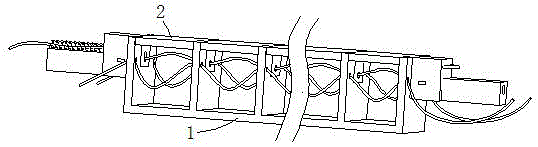

[0030] In this embodiment, the following tobacco leaf weaving and binding devices are used to realize the binding of fresh tobacco leaves, such as Figure 1-2 As shown, a tobacco leaf weaving and binding device includes a main rod frame 1 and a secondary rod frame 2 that are elongated as a whole. The main rod frame 1 and the secondary rod frame 2 each have a docking side for docking. The main rod frame 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com