Soybean isolate protein processing method

A technology of soybean protein isolate and processing method, applied in the field of soybean protein isolate production, can solve the problem of not clearly distinguishing surimi products, soybean protein products, etc., and achieve the effects of improving flavor, increasing sedimentation rate, and delicate taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

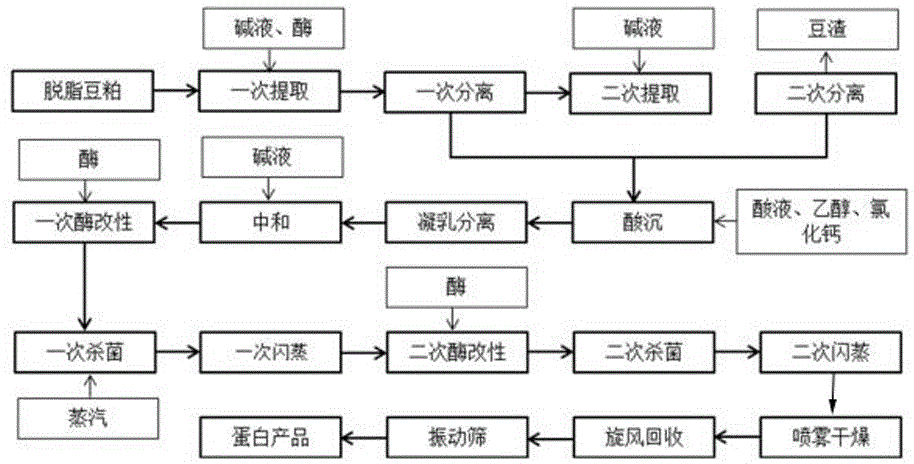

Method used

Image

Examples

Embodiment 1

[0031] (1) Primary extraction: mix low-temperature defatted soybean meal with water at a ratio of 1:12, water temperature is 20°C, adjust the pH value to 8.0 with liquid NaOH, and then add alkaline protease with a substrate concentration of 0.1‰ (enzyme activity: 40,000 U / g ), low-speed stirring and leaching for 40 minutes, stirring speed 60r / min;

[0032] (2) Primary centrifugal separation: After the primary extraction is completed, the extract is centrifuged with a horizontal screw discharge centrifuge, the solid phase 1 enters the secondary extraction process, and the liquid phase 1 enters the acid precipitation process;

[0033] (3) Secondary extraction: add the solid phase 1 after the first extraction to light alkaline water with 6 times the amount of soybean meal for water dissolving and rinsing (the light alkaline water needs to be prepared with ice water or steam, water and 30% sodium hydroxide to make 20 ℃, PH12 light alkali aqueous solution, and then add it to the se...

Embodiment 2

[0044](1) Primary extraction: mix low-temperature defatted soybean meal with water at a ratio of 1:10, water temperature is 20°C, adjust the pH value to 7.0 with liquid NaOH, and then add alkaline protease with a substrate concentration of 0.1‰ (enzyme activity: 40,000 U / g ), low-speed stirring and leaching for 40 minutes, stirring speed 60r / min;

[0045] (2) Primary centrifugal separation: After the primary extraction is completed, the extract is centrifuged with a horizontal screw discharge centrifuge, the solid phase 1 enters the secondary extraction process, and the liquid phase 1 enters the acid precipitation process;

[0046] (3) Secondary extraction: the solid phase 1 after the primary extraction is added to light alkaline water with 7 times the amount of soybean meal for water dissolving and rinsing (the light alkaline water needs to be prepared with ice water or steam, water and 30% sodium hydroxide to make 20 ℃, PH12 light alkali aqueous solution, and then add it to ...

Embodiment 3

[0057] (1) Primary extraction: mix low-temperature defatted soybean meal with water at a ratio of 1:13, water temperature 35°C, adjust pH value to 8.3 with liquid NaOH, and then add alkaline protease with a substrate concentration of 0.3‰ (enzyme activity 40,000 U / g ), low-speed stirring and leaching for 50 minutes, stirring speed 60r / min;

[0058] (2) Primary centrifugal separation: After the primary extraction is completed, the extract is centrifuged with a horizontal screw discharge centrifuge, the solid phase 1 enters the secondary extraction process, and the liquid phase 1 enters the acid precipitation process;

[0059] (3) Secondary extraction: add the solid phase 1 after the first extraction to light alkaline water with 7 times the amount of soybean meal for water dissolving and rinsing (the light alkaline water needs to be prepared with ice water or steam, water and 30% sodium hydroxide to make 40 ℃, PH13 light alkali aqueous solution, and then add it to the secondary ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com