Technique for extracting fragrance of tea beverage

A tea beverage and process technology, applied in the field of tea beverage titration process, can solve problems such as loss of aroma components of tea beverages, and achieve the effects of retaining aroma, avoiding heat deterioration, and avoiding loss of aroma components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

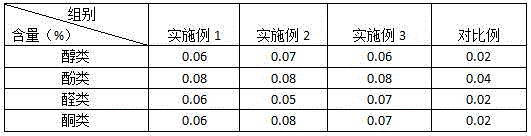

Examples

Embodiment 1

[0019] Embodiment 1: a kind of process for increasing the aroma of tea beverage, comprising the following steps:

[0020] Step 1. Infiltration: Prepare finished tea leaves with fresh smell and no mold, prepare water at 16°C, soak the tea leaves in water for 2 hours;

[0021] Step 2. Distillation: Take the tea leaves from step 1 out of the water, put the tea leaves in the freezer to freeze and freeze them, then put them into the still pot, put in steam at 180°C for 1 hour, collect the distillate, and distill Put the liquid into a light-tight airtight container, and store it at room temperature for future use;

[0022] Step 3, decocting: After distilling out the distillate, transfer the tea and tea leaves in the stilling pot to the frying pot for 0.5 hours, stop heating, and then naturally cool at room temperature for 12 hours;

[0023] Step 4. Filtration and pressing: use a filter to filter and separate the tea and tea leaves in step 3, and collect the tea; then press and sepa...

Embodiment 2

[0027] Embodiment 2: a kind of process for increasing the aroma of tea beverage, comprising the following steps:

[0028] Step 1. Infiltration: prepare finished tea leaves with fresh smell and no mold, prepare water at 14°C, and soak the tea leaves in water for 3 hours;

[0029] Step 2. Distillation: Put the tea leaves and clear water into a still pot, distill at 200°C for 1.5 hours, collect the distillate, put the distillate into a light-tight airtight container, and store it sealed at room temperature for later use;

[0030] Step 3, decocting: transfer the tea water and tea leaves in the distillation pot to the decoction pot for 0.6 hours, stop heating, and then naturally cool at room temperature for 12 hours;

[0031] Step 4. Filtration and pressing: use a filter to filter and separate the tea and tea leaves in step 3, and collect the tea; then press and separate the tea leaves. During the pressing and separation, use water at 20°C to pour the tea leaves, and press and sepa...

Embodiment 3

[0034] Embodiment 3: a kind of process for increasing the aroma of tea beverage, comprising the following steps:

[0035] Step 1. Infiltration: prepare finished tea leaves with fresh smell and no mold, prepare water at 12°C, soak the tea leaves in water for 3 hours;

[0036] Step 2. Distillation: Put the tea leaves and clear water into a still pot, distill at 150°C for 1.5 hours, collect the distillate, put the distillate into a light-tight airtight container, and keep it sealed at room temperature for future use;

[0037] Step 3, decocting: transfer the tea and tea leaves in the distillation pot to the decoction pot for 0.8 hours, stop heating, and then naturally cool at room temperature for 12 hours;

[0038] Step 4. Filtration and pressing: use a filter to filter and separate the tea and tea leaves in step 3, and collect the tea; then press and separate the tea leaves, use water at 25°C to pour the tea leaves during the pressing and separation, and press and separate for fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com