Snail meat washing machine

A washing machine and screw meat technology, which is applied in shrimp/lobster processing, etc., can solve the problems of low processing efficiency, time-consuming and labor-consuming, and achieve the effect of simple structure, convenient use, and easy discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

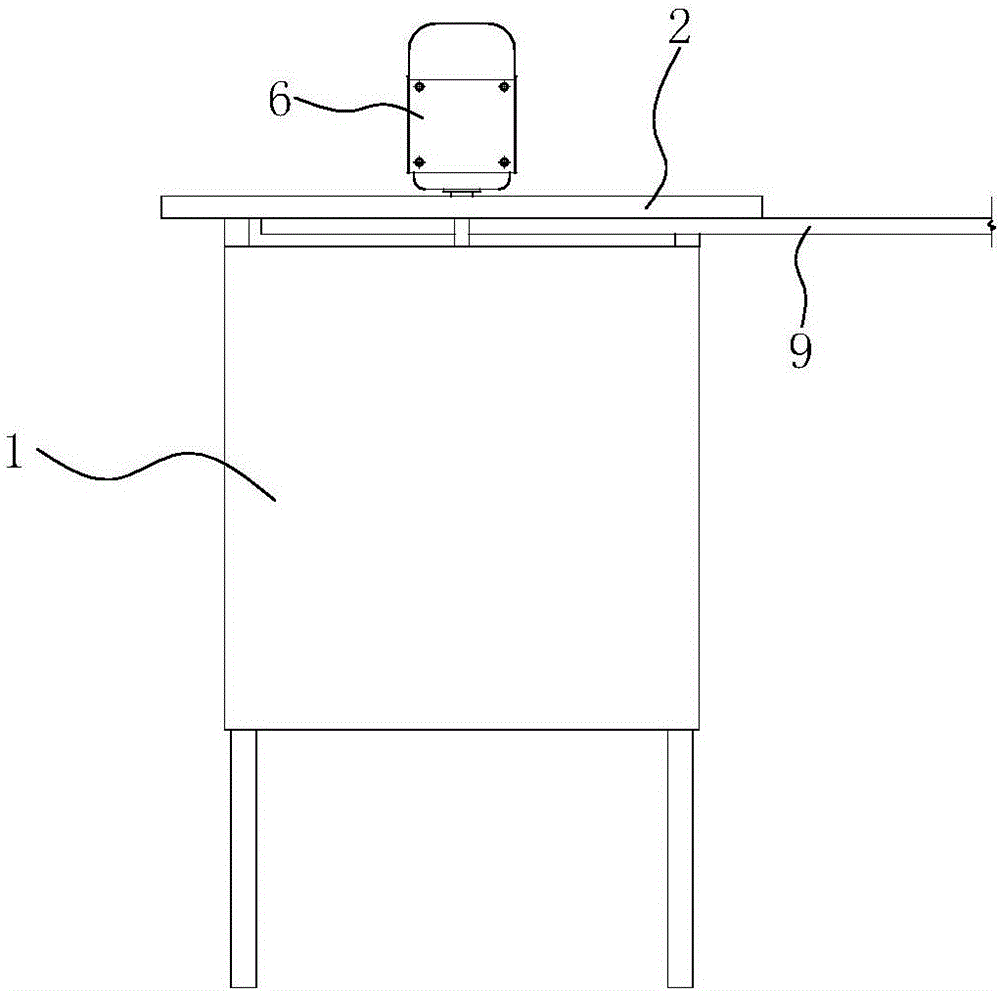

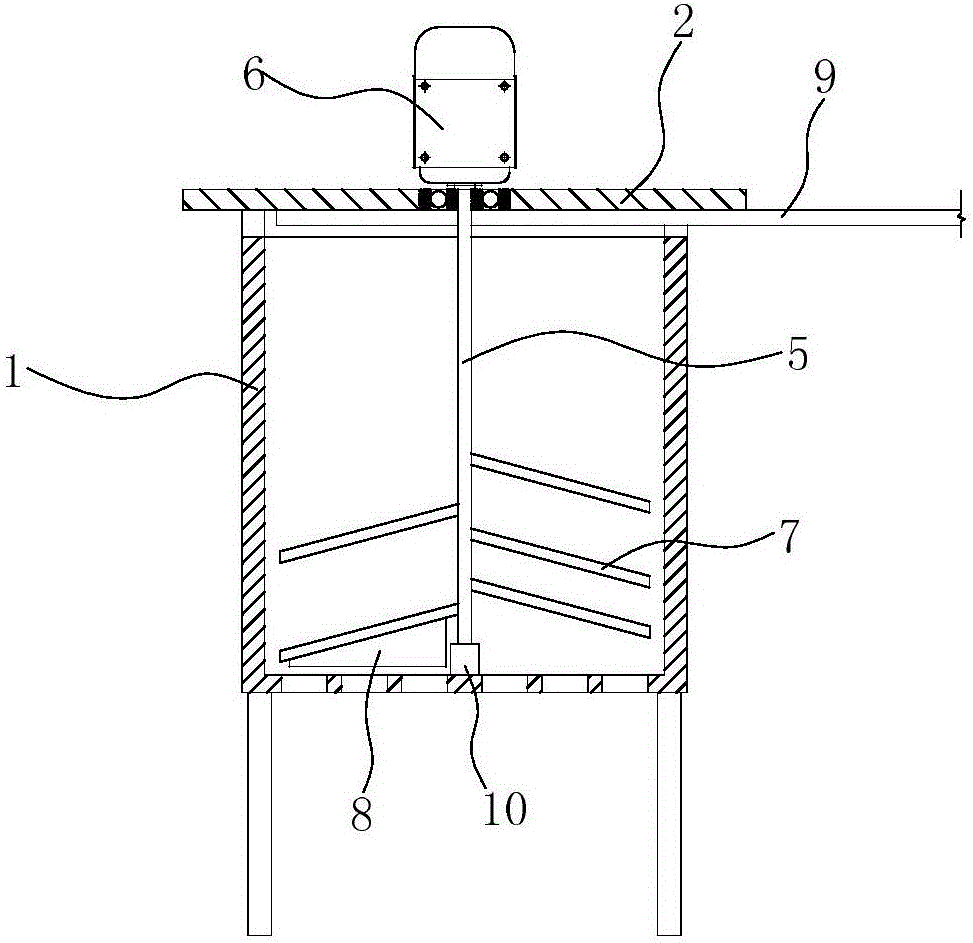

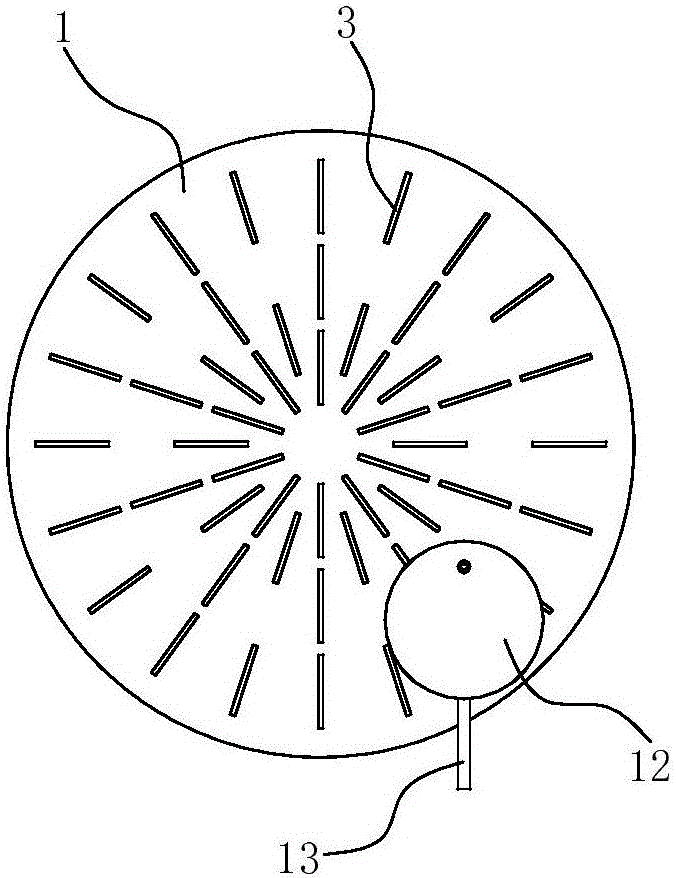

[0021] combine Figure 1-7 The screw meat cleaning machine shown includes a cleaning bucket 1, a stirring mechanism and a water supply mechanism for injecting water into the cleaning bucket 1. The cleaning bucket 1 is a carrier for rotating the screw meat. The stirring mechanism can stir the screw meat in the cleaning bucket 1. The water supply mechanism can inject cleaning water into the cleaning bucket 1. The water supply mechanism has many specific structures, such as , the water supply mechanism is a water supply hose, and the water outlet end of the water supply hose can be directly aligned with the inside of the cleaning bucket 1. Of course, the water supply mechanism can also be a shower head whose spray direction faces the inside of the cleaning bucket 1. In order to flexibly control the amount of water, usually the water supply mechanism also includes a valve to control the flow.

[0022] combine figure 1 , 2 As shown in and 5, the top of the cleaning bucket 1 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com