Plant preservative and preparation method thereof and application

The technology of a plant preservative and madder is applied in the field of plant preservative and its preparation, which can solve the problems affecting the commercial value of fresh cut flowers, the wilting life of flowers, lack of nutrients, etc., so as to prolong the market supply time, improve the commercial value and ornamental value. Good value, fresh-keeping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

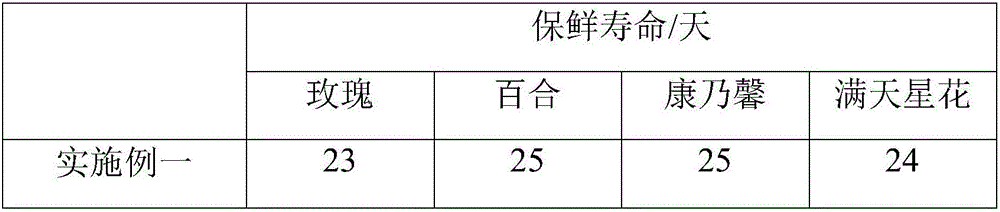

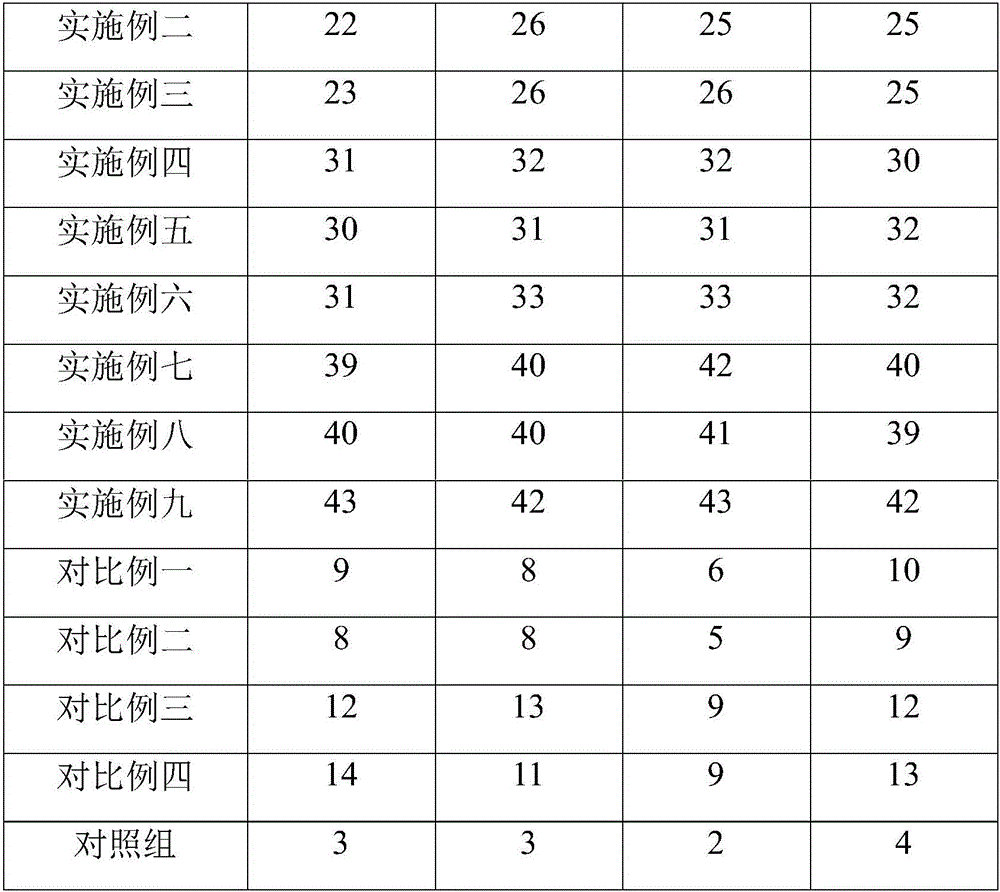

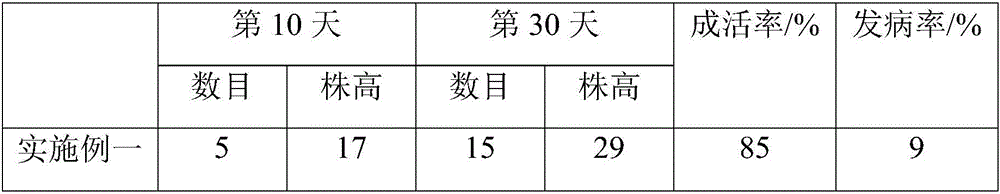

Examples

Embodiment 1

[0037] The invention provides a plant antistaling agent. The raw material components are calculated in parts by weight, including: 4 parts by weight of saponins, 2 parts by weight of madder, 1.5 parts by weight of camphor leaves, 8 parts by weight of honeysuckle, 0.3 parts by weight of fish oil, and 2 parts by weight of licorice 2 parts by weight of peppermint, 3 parts by weight of potassium dihydrogen phosphate and 1 part by weight of sodium chloride.

[0038] According to above-mentioned raw material component, adopt the preparation method of plant antistaling agent provided by the invention, prepare the required plant antistaling agent of the present invention:

[0039] S101: Grind saponins, madder, and camphor leaves and soak them in water, then use 20% by mass acetic acid aqueous solution to perform the first extraction, filter the first extracted product, collect the first filtrate and adjust the first The pH of the filtrate was 5.0. Wherein, the conditions of the first...

Embodiment 2

[0043] The invention provides a plant antistaling agent. The raw material components are calculated in parts by weight, including: 5 parts by weight of saponins, 1 part by weight of madder, 2 parts by weight of camphor leaves, 6 parts by weight of honeysuckle, 0.5 parts by weight of fish oil, and 1 part by weight of licorice part, 3 parts by weight of peppermint, 1 part by weight of potassium dihydrogen phosphate and 2 parts by weight of sodium chloride.

[0044] According to above-mentioned raw material component, adopt the preparation method of plant antistaling agent provided by the invention, prepare the required plant antistaling agent of the present invention:

[0045] S101: Grind saponins, madder, and camphor leaves and soak them in water, then use 35% acetic acid aqueous solution for the first extraction, filter the products after the first extraction, collect the first filtrate and adjust the first The pH of the filtrate was 4.8. Wherein, the conditions of the first ...

Embodiment 3

[0049] The invention provides a plant antistaling agent. The raw material components are calculated in parts by weight, including: 4.5 parts by weight of saponins, 1.5 parts by weight of madder, 1.8 parts by weight of camphor leaves, 7 parts by weight of honeysuckle, 0.4 parts by weight of fish oil, and 1.5 parts by weight of licorice 3 parts by weight of peppermint, 2 parts by weight of potassium dihydrogen phosphate and 1.5 parts by weight of sodium chloride.

[0050] According to above-mentioned raw material component, adopt the preparation method of plant antistaling agent provided by the invention, prepare the required plant antistaling agent of the present invention:

[0051] S101: Grind saponins, madder, and camphor leaves and soak them in water, then use 28% by mass acetic acid aqueous solution to perform the first extraction, filter the first extracted product, collect the first filtrate and adjust the first The pH of the filtrate was 4.9. Wherein, the conditions of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com