A Furnace Parameter Measurement System for Vacuum Fiber Glass

A technology of fiber glass and parameter measurement, which is applied in the direction of polycrystalline material growth, crystal growth, single crystal growth, etc., can solve the problems of large error, fracture of long crystal rod, and long time of artificial reading, so as to solve the problem of large error and reduce lateral The probability of breaking and the effect of shortening the measurement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

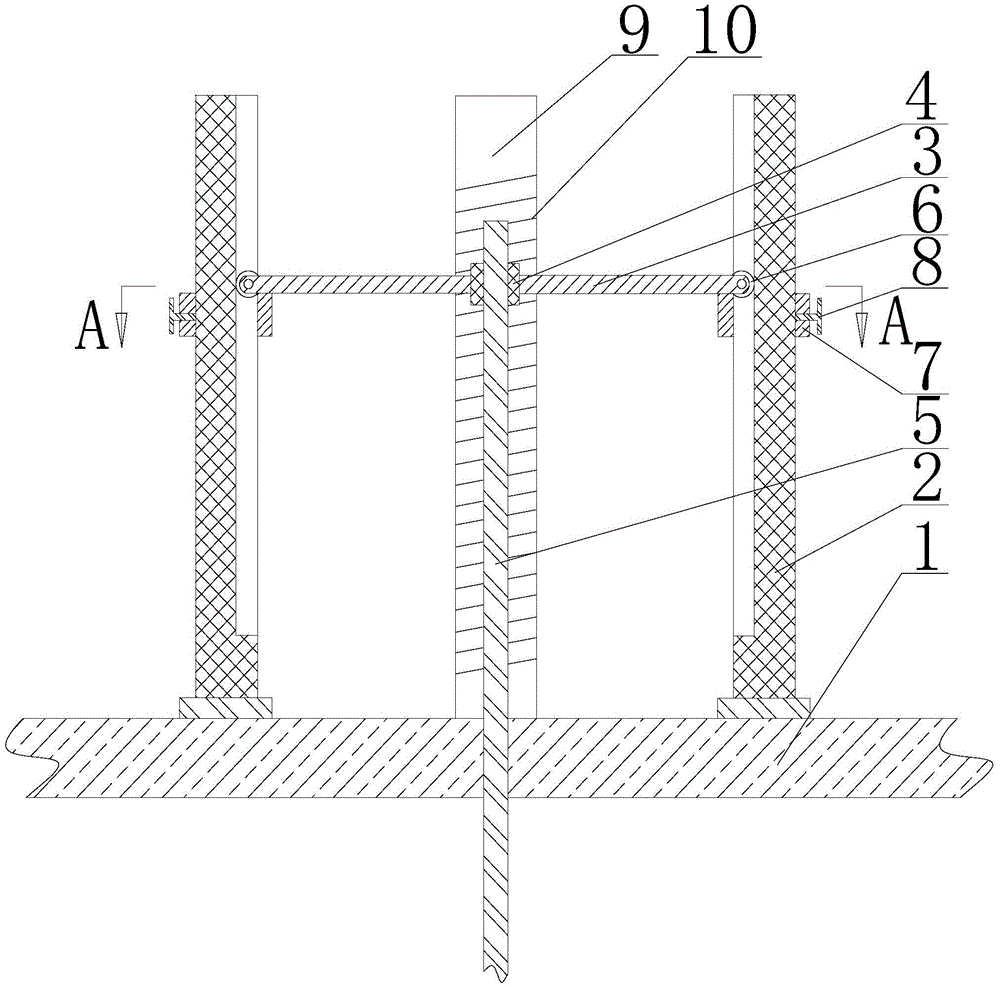

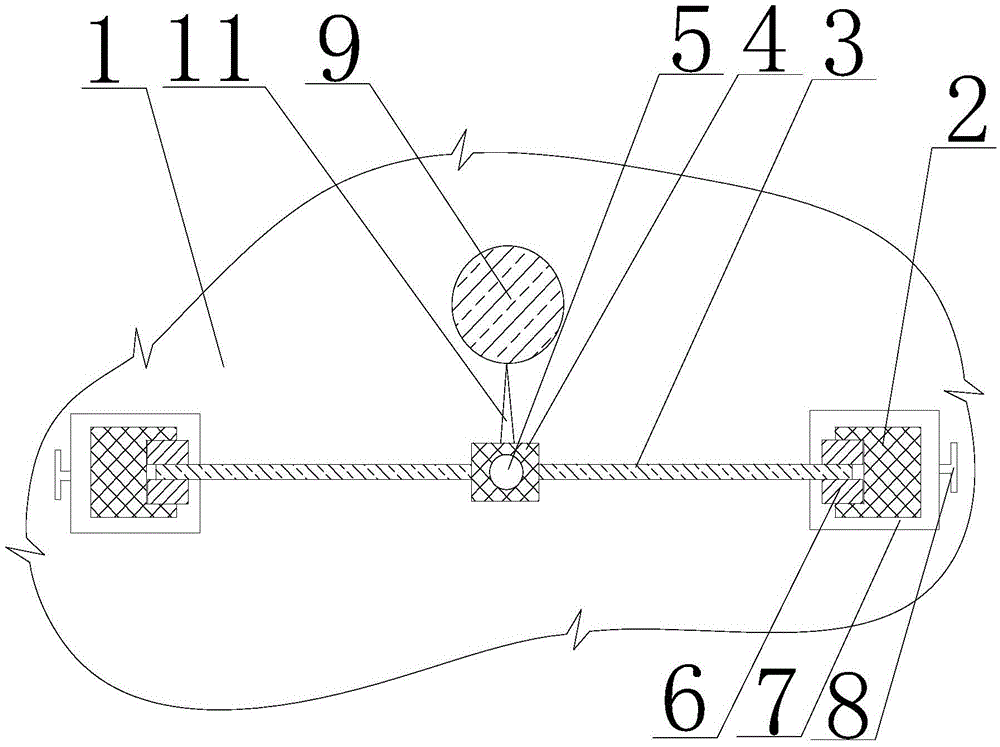

[0024] like figure 1 As shown, a furnace parameter measurement system for vacuum fiber glass of the present invention includes two chutes 2 installed outside the long crystal hole on the top of the ingot furnace 1, the chutes 2 are placed vertically, and the two chutes 2 have concave grooves, the concave grooves of the two chute 2 stand opposite and are placed in parallel, a sliding frame 3 is installed in the chute 2, and a roller 6 is installed at the end of the sliding frame 3, and the roller 6 is Restricted in the chute 2, the sliding frame 3 can be pushed to move up and down freely along the chute 2 in the vertical direction, and a clamp 4 is set on the sliding frame 3, the clamp 4 is located directly above the elongated crystal hole, and is clamped by the clamp 4 Holding the long crystal rod 5, the sliding frame 3 moves up and down in the chute 2 to promote the insertion and extraction of the long crystal rod, and the locking ring 7 is installed on the chute 2, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com