Aluminum alloy car body welding assembly tool

An aluminum alloy vehicle body and assembly tooling technology, which is applied in metal processing, welding equipment, auxiliary welding equipment, etc., can solve the problems of various types and poor versatility, achieve strong versatility, enhance versatility, and ensure welding quality and accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

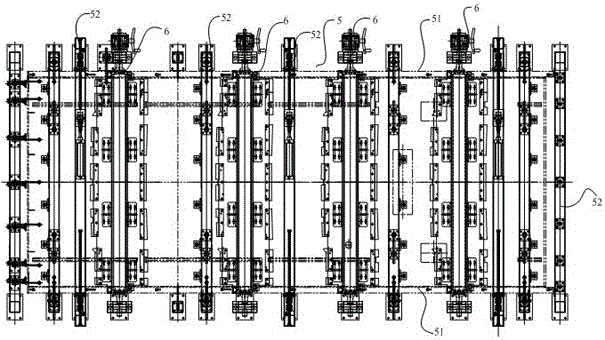

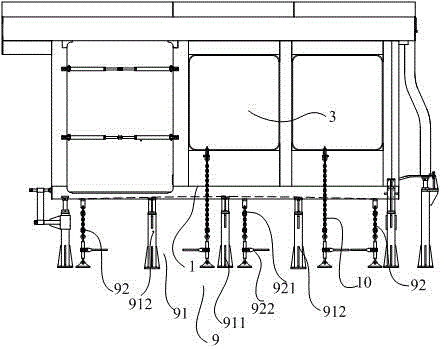

[0031] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods. The present invention proposes an embodiment of an aluminum alloy vehicle body welding assembly tool. Figure 1-Figure 8 As shown, the aluminum alloy car body includes an underframe 1, a roof 2, a side wall 3 and an end wall, side beams 4 are arranged on both sides of the roof 2, and the various parts of the aluminum alloy car body are assembled first. Welding, that is, the underframe 1, the roof 2, the end wall and the side wall 3 are welded respectively. Specifically, the roof 2 and the underframe 1 are welded by a CNC gantry automatic welding machine, and the front and back sides of the roof 2 are welded and fixed using the roof clamping and fixing device in this embodiment. Specifically, this embodiment The roof clamping and fixing device in the vehicle comprises a roof support frame 5, an arc pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com