Au25 nanosphere synthetic method and Au25 nanospheres

A technology of nanospheres and au25, which is applied in the field of nanomaterials, can solve problems such as difficult synthesis, achieve the effects of easy purification, simple and convenient synthesis route, and improved activity and catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

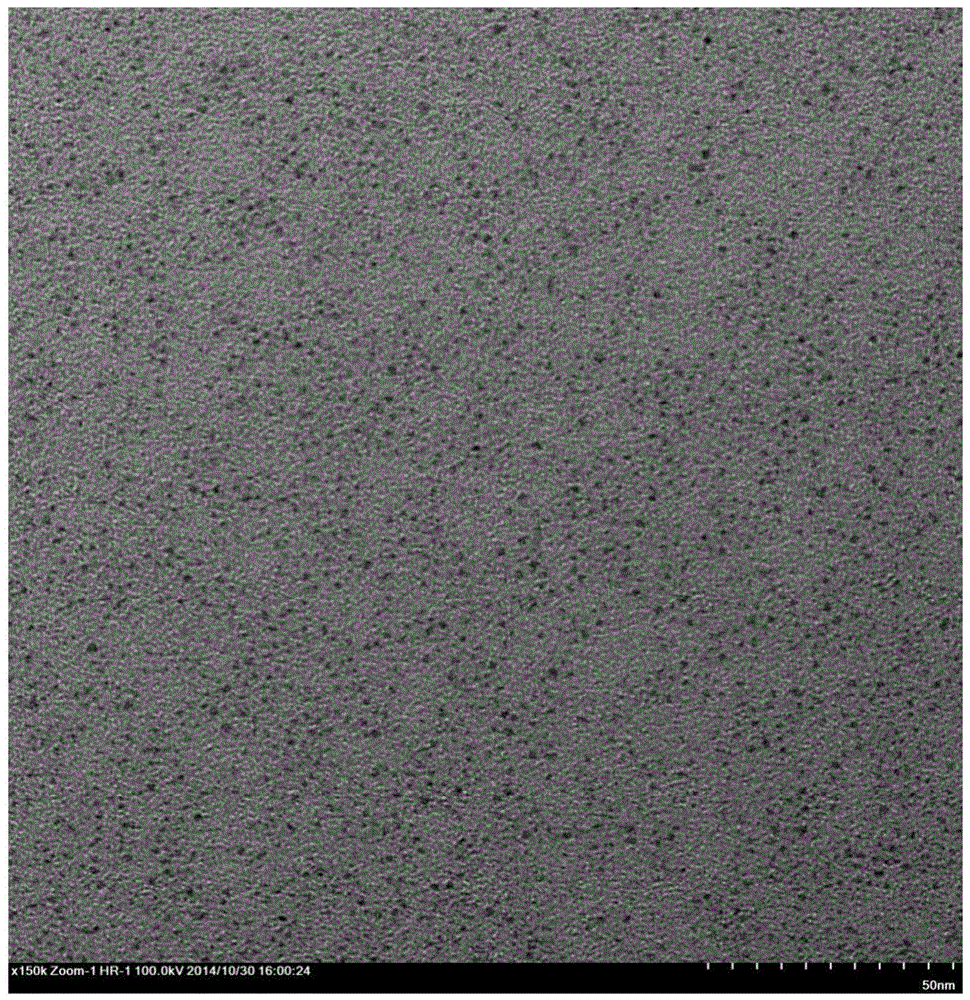

Image

Examples

Embodiment 1

[0022] Embodiment 1: stirring speed 1000rpm

[0023] A Simple and Efficient Synthesis of Au 25 (2-NapS) 18 A method for synthesizing nanoclusters, specifically comprising the following steps:

[0024] (1) Weigh 68 mg of HAuCl 4 ·3H 2 O is placed in a 50ml three-necked round-bottomed flask as a reaction raw material, dissolved in 15ml of acetone, added with 104.6mg of tetra-n-octylammonium bromide (TOAB), stirred for 30min, until the color of the solution changes from golden yellow to orange After turning red, weigh 79.5mg of 2-naphthylthiol mercapto ligand, and when the color of the solution becomes lighter and lighter, weigh 62.4mg of sodium borohydride and dissolve it in 3ml of ice water. After shaking and dissolving, slowly dissolve the sodium borohydride solution Add it into the above-mentioned three-neck flask, control the stirring time at 1000 rpm for 5-6 hours, then stop the reaction, spin the reaction system to dryness, wash the solid with methanol, then extract it...

Embodiment 2

[0026] Embodiment 2: stirring speed 700rpm

[0027] (1) Weigh 68 mg of HAuCl 4 ·3H 2 O is placed in a 50ml three-necked round-bottomed flask as a reaction raw material, dissolved in 15ml of acetone, added with 104.6mg of tetra-n-octylammonium bromide (TOAB), stirred for 30min, until the color of the solution changes from golden yellow to orange After turning red, weigh ~9.5mg of 2-naphthylthiol mercapto ligand, and when the color of the solution becomes lighter and lighter, weigh 62.4mg of sodium borohydride and dissolve it in 3ml of ice water. After shaking to dissolve, slowly dissolve Add the sodium borohydride solution into the three-necked flask above, control the stirring time at 1000rpm for 5-6 hours, then stop the reaction, spin the reaction system to dryness, wash the solid with methanol, then extract it with acetonitrile, remove insolubles by centrifugation, and dry the acetonitrile solution to obtain crude product.

[0028] (2) Place all the crude product synthesi...

Embodiment 3

[0030] Example 3: Changing the dissolved NaBH 4 The solvent is ethanol

[0031] (1) Weigh 68 mg of HAuCl 4 ·3H 2O is placed in a 50ml three-necked round-bottomed flask as a reaction raw material, dissolved in 15ml of acetone, added with 104.6mg of tetra-n-octylammonium bromide (TOAB), stirred for 30min, until the color of the solution changes from golden yellow to orange After turning red, weigh 79.5 mg of 2-naphthylthiol mercapto ligand, and when the color of the solution becomes lighter and lighter, weigh 62.4 mg of sodium borohydride and dissolve it in 3 ml of absolute ethanol. After shaking and dissolving, slowly Add the sodium borohydride solution into the three-neck flask above, control the stirring time at 1000rpm for 5-6 hours, then stop the reaction, spin the reaction system to dryness, wash the solid with methanol, then extract it with acetonitrile, remove insoluble matter by centrifugation, and dry the acetonitrile solution A crude product was obtained.

[0032]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com