Oxidized graphene/silicon dioxide/high-molecular polymer composite nano-filtration membrane preparation method

A high molecular polymer and composite nanofiltration membrane technology, applied in the direction of alkali metal oxides/hydroxides, alkali metal compounds, chemical instruments and methods, etc., can solve the problem of low strength of electrospun fiber membranes, failure to achieve filtration effects, Electrospun membrane lacks economy and other problems, and achieves the effect of low raw material price, convenient operation of process equipment, and favorable industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

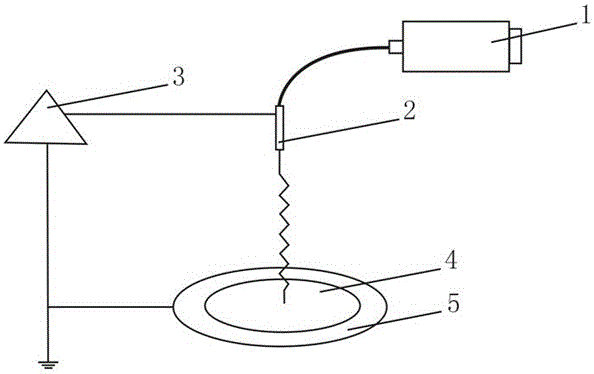

[0030] The invention discloses a preparation method of graphene oxide / silicon dioxide / polymer composite nanofiltration membrane, which specifically comprises the following steps:

[0031] (1) Spread the non-woven fabric base material with an area density of 30g / ㎡ on the internally grounded metal plate 5;

[0032] (2) Mix graphene oxide and nano-silicon dioxide in proportion in a reaction vessel, stir and react at 10°C for 1 hour under non-neutral conditions, and extract the product to obtain a graphene oxide / silicon dioxide composite;

[0033] (3) Dissolve the high molecular polymer polyacrylonitrile, graphene oxide / silica composite with a mixing ratio of 5:4 in a solvent with a mixing ratio of methanol and ethanol of 3:1, stir until completely dissolved, and obtain a spinning Solution, the mass percentage concentration of spinning solution is 8wt%;

[0034] (4) Add the spinning solution prepared in step (3) into the syringe pump 1, control the ambient humidity to 20%, and th...

Embodiment 2

[0038] The invention discloses a preparation method of graphene oxide / silicon dioxide / polymer composite nanofiltration membrane, which specifically comprises the following steps:

[0039] (1) Spread the non-woven fabric base material with an area density of 50g / ㎡ on the internally grounded metal plate 5;

[0040] (2) Mix graphene oxide and nano-silicon dioxide in proportion in a reaction vessel, stir and react at 40°C for 8 hours under non-neutral conditions, and extract the product to obtain a graphene oxide / silicon dioxide composite;

[0041] (3) Dissolve the high molecular polymer polyvinylidene fluoride and graphene oxide / silica composite with a mixing ratio of 5:4 in a solvent with a mixing ratio of formic acid and acetic acid of 3:1, and stir until completely dissolved to obtain a spinning Silk solution, the mass percentage concentration of spinning solution is 15wt%;

[0042] (4) Add the spinning solution prepared in step (3) into the syringe pump 1, control the ambien...

Embodiment 3

[0046] The invention discloses a preparation method of graphene oxide / silicon dioxide / polymer composite nanofiltration membrane, which specifically comprises the following steps:

[0047] (1) Spread the non-woven fabric base material with an area density of 75g / ㎡ on the internally grounded metal plate 5;

[0048] (2) Mix graphene oxide and nano-silicon dioxide in proportion in a reaction vessel, stir and react at 80°C for 15 hours under non-neutral conditions, and extract the product to obtain a graphene oxide / silicon dioxide composite;

[0049] (3) Dissolve high molecular polymer polyurethane and graphene oxide / silica composite in a mixing ratio of 5:4 in a solvent of formic acid and acetic acid in a mixing ratio of 3:1, and stir until completely dissolved to obtain a spinning solution. The mass percentage concentration of spinning solution is 20wt%;

[0050] (4) Add the spinning solution prepared in step (3) into the syringe pump 1, control the ambient humidity to 60%, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com