A kind of antibacterial repair function dressing and preparation method thereof

A functional, bacterial cellulose technology, applied in the field of biomedical materials, can solve the selection defects of functional material collagen type, function and molecular weight refinement, failure to obtain an ideal composite multifunctional medical dressing, failure to form a composite type multi-functional medical dressings, etc., to reduce pigmentation, promote wound healing, and promote wound healing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

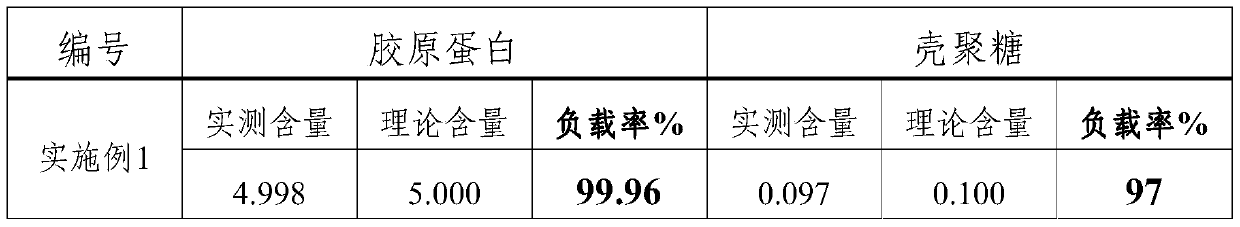

Embodiment 1

[0052] This example provides an antibacterial and repairing functional dressing, preparation requirements: specification: 5cm×5cm; quantity: 100 pieces

[0053] Preparation steps:

[0054] Step 1: Purification of bacterial cellulose membrane: select 10 large pieces of fresh bacterial cellulose membrane, put them in a beaker and wash them three times with distilled water, squeeze about 70% of the water each time, remove the impurities on the surface of the bacterial cellulose membrane, and set aside. Prepare 6L of 1mol / L NaOH solution, pour the above solution into a beaker equipped with a bacterial cellulose membrane, start heating and keep stirring. Control the temperature at 95°C and time it for 2 hours.

[0055] After the completion, rinse the bacterial cellulose membrane with distilled water repeatedly until the pH is between 5 and 7, and pass ozone for 1 hour, and the ozone concentration is 1.5mg / L; after the ozone is passed, stir for 2 hours, After passing the test, squ...

Embodiment 2

[0064] This example provides an antibacterial and repairing functional dressing, preparation requirements: specification: 10cm×15cm; quantity: 100 pieces

[0065] Preparation steps:

[0066] Step 1: Purification of bacterial cellulose membrane: select 25 large pieces of fresh bacterial cellulose membrane, put them in a stainless steel bucket and wash them three times with purified water, squeeze about 70% of the water each time, remove the impurities on the surface of the bacterial cellulose membrane, and set aside. Prepare 12L of 2mol / L KOH solution, pour the above solution into a stainless steel bucket equipped with a bacterial cellulose membrane, start heating and keep stirring. Control the temperature at 70°C and count for 24 hours.

[0067] After the completion, rinse the bacterial cellulose membrane with purified water repeatedly until the pH is between 5 and 7, and pass ozone for 2 hours, and the ozone concentration is 0.5mg / L; after the ozone is passed, stir and count...

Embodiment 3

[0073] This example provides an antibacterial and repairing functional dressing, preparation requirements: specification: 10cm×20cm; quantity: 60 pieces

[0074] Preparation steps:

[0075] Step 1: Purification of bacterial cellulose membrane: select 20 large pieces of fresh bacterial cellulose membrane, put them in a beaker and wash them three times with distilled water, squeeze about 70% of the water each time, remove the impurities on the surface of the bacterial cellulose membrane, and set aside. Prepare 10L of 2mol / L NaOH solution, pour the above solution into a beaker equipped with a bacterial cellulose membrane, start heating and keep stirring. Control the temperature at 50°C and count for 36 hours.

[0076] After the completion, rinse the bacterial cellulose membrane with distilled water repeatedly until the pH is between 5 and 7, and pass ozone for 2.5 hours, and the ozone concentration is 1.0 mg / L; after the ozone is passed, stir for 2 hours, After passing the test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com