Rapidly positioned column foot anchor bolt structure

An anchor bolt, fast technology, applied in the direction of building construction, building material processing, construction, etc., can solve the problems of slow speed and low efficiency, and achieve the effects of strong structure, improved engineering quality, and stable and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

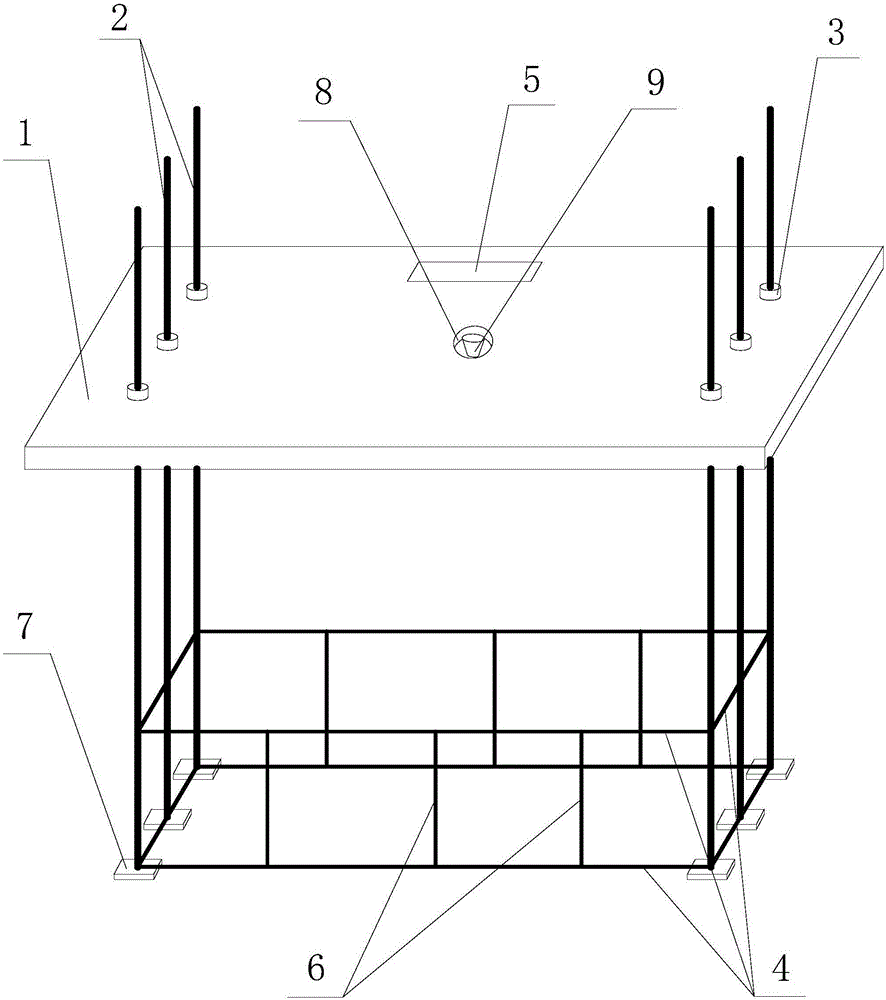

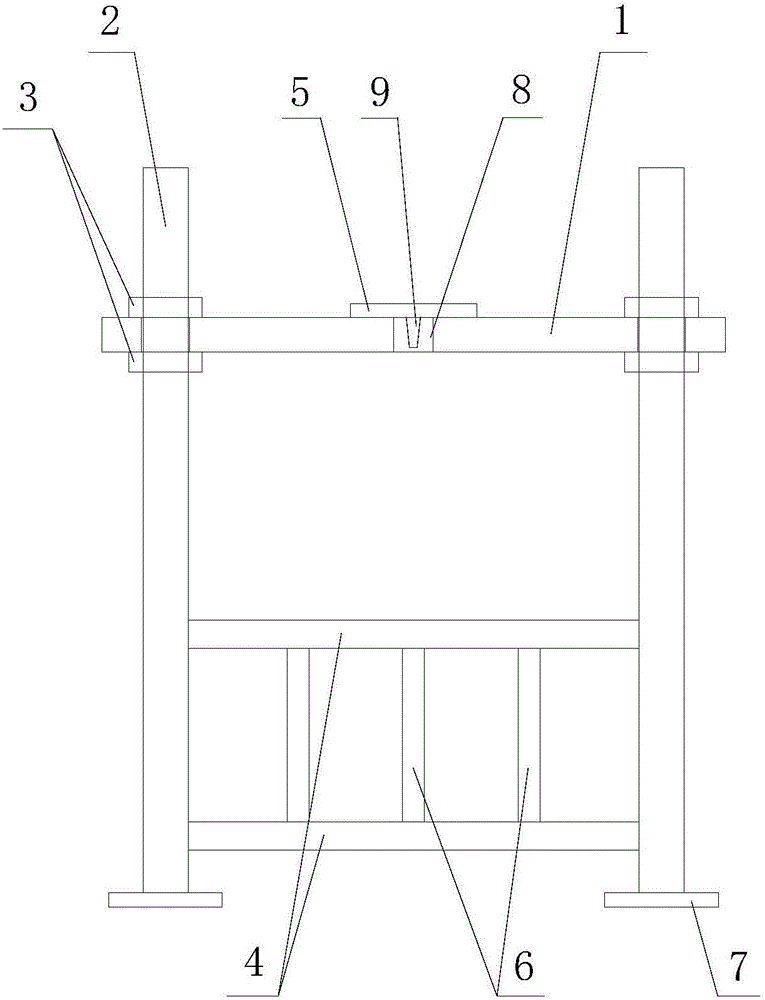

[0026] Such as figure 1 and figure 2 A fast-positioning column foot anchor bolt structure shown includes a positioning template 1, anchor bolt holes are set on the positioning template 1, anchor bolts 2 are inserted into the anchor bolt holes, and the positioning template 1 is fixed to the anchor bolt 2 by nuts 3 , the axes of each anchor bolt 2 are parallel, and two adjacent anchor bolts 2 are fixedly connected with two transverse ribs 4 distributed up and down along the axis direction of the anchor bolt 2, and all transverse ribs 4 are located on the lower side of the positioning template 1, and The transverse rib 4 is perpendicular to the axis of the anchor bolt 2; the vertical rib 6 is fixedly connected between the upper and lower adjacent two transverse ribs 4; the upper surface of the positioning template 1 is provided with a level 5; the center of the positioning template 1 is provided with a through hole 8. The beam emitting device 9, the emitting end of the beam emi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com