Sand mixer with enhanced preliminary mixing function

A technology of sand mixer and molding sand, which is applied to the cleaning/processing machinery of casting mold materials, manufacturing tools, casting molding equipment, etc., which can solve the problems of low mechanical efficiency of sand mixer, improve mixing efficiency and improve mechanical Performance, the effect of improving the contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

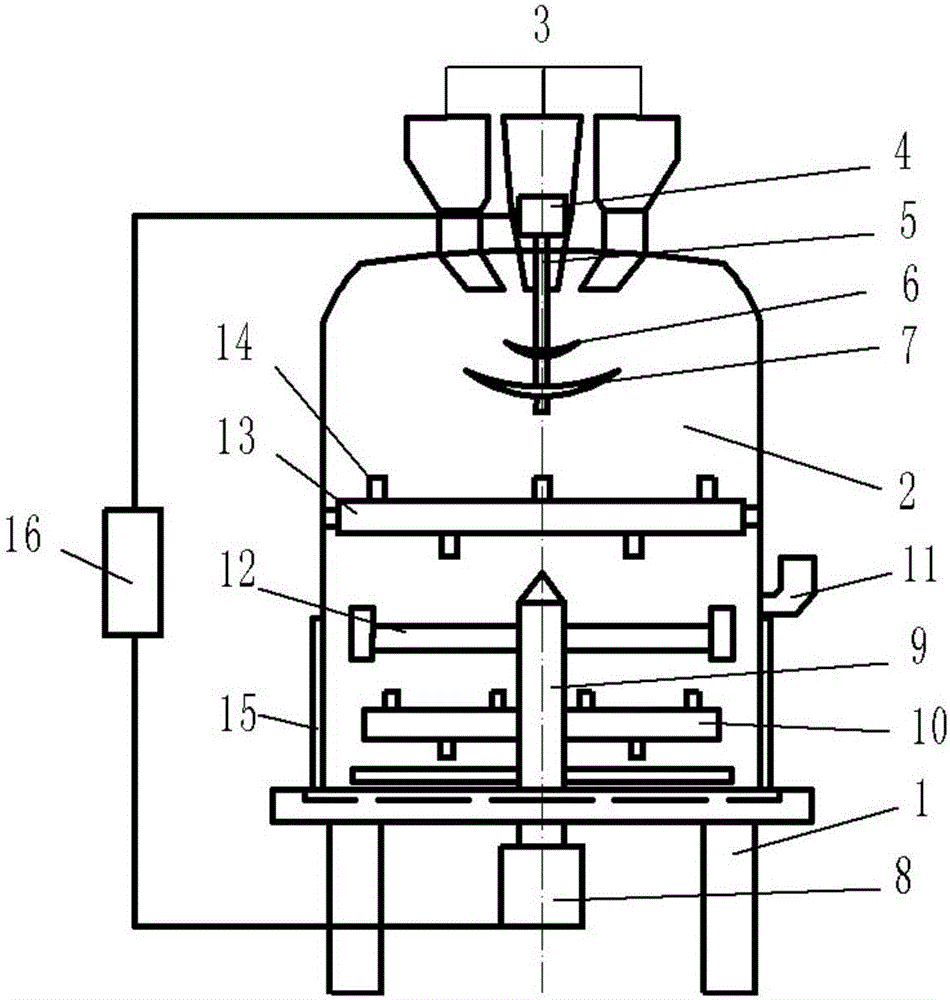

[0027] Such as figure 1 As shown, the sand mixer of the present invention has a base 1 and a main mixing bin 2 installed on the base. Three feeding ports 3 are installed on the upper part of the main mixing bin 2, which can be used to supply different types of molding sand such as new sand and old sand. It can also be used to supply molding sand, binder and auxiliary materials at the same time. The above-mentioned feed port 3 is also connected with a quantitative feeding device (not shown in the figure) with a metering function. The primary mixing disc is used for preliminary mixing of the materials supplied by the feed port. The primary mixing disc includes a primary mixing drive mechanism 4, a primary mixing transmission shaft 5 and a rotating disc installed on the primary mixing transmission shaft. The primary mixing transmission shaft 5 passes through the main mixing The top of the bin 2 is connected to the primary mixing drive mechanism 4 located outside the top of the ma...

Embodiment 2

[0036] As an improvement to the present invention, in this embodiment, for the initial mixing disc, more than two first-stage rotating disks 6 at the same level can be set, and each first-stage rotating disk 6 is connected with the second-stage rotating disk. 7 different speeds and steering movements, such as figure 2 As shown, the transmission connection can be realized in the following way: the original hybrid transmission shaft is divided into a driving transmission shaft and several driven transmission shafts, each first-stage rotating disc 6 has its own independent driven transmission shaft, and the shaft end Connect the driven gear 17, the shaft end of the driving transmission shaft of the second stage rotating disk 7 is connected to the driving gear 18, the driving transmission shaft drives the driving gear 18 to rotate under the drive of the primary mixing drive mechanism 4, and the driving gear 18 drives the driven gear 17 to rotate , the driven gear 17 drives the dr...

Embodiment 3

[0039] Different from Embodiment 2, as an improvement to the primary mixing disk of the present invention, in this embodiment, the differential speed control of the first-stage rotating disk 6 and the second-stage rotating disk 7 can be realized without adding a new shaft position, Such as image 3 As shown, the transmission connection can be realized in the following way: the original mixed transmission shaft is divided into the inner shaft of the active transmission and the outer shaft of the driven transmission, the second-stage rotating disk 7 is connected to the inner shaft of the active transmission, and the first-stage rotating disk 6 is connected to the driven transmission shaft. Drive the outer shaft, the shaft end of the active transmission inner shaft is connected to the driving gear 18, the shaft end of the driven transmission outer shaft is connected to the ring gear 19, the driving transmission inner shaft drives the driving gear 18 to rotate under the drive of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com