Fibre composite material component, and method for producing a fibre composite material component

A fiber composite material and component technology, which is applied in the field of manufacturing fiber composite material components, can solve the problem of many scraps of materials, and achieve the effect of simple structure, light weight and reduction of scraps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

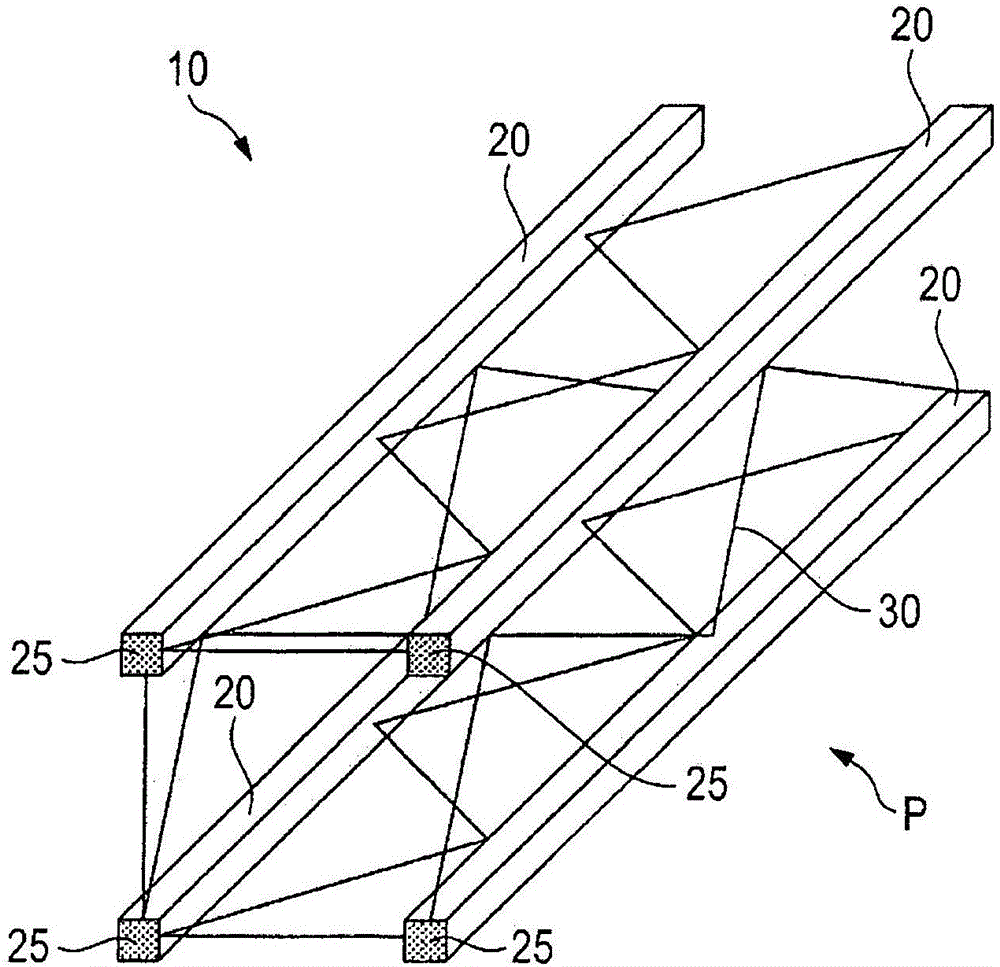

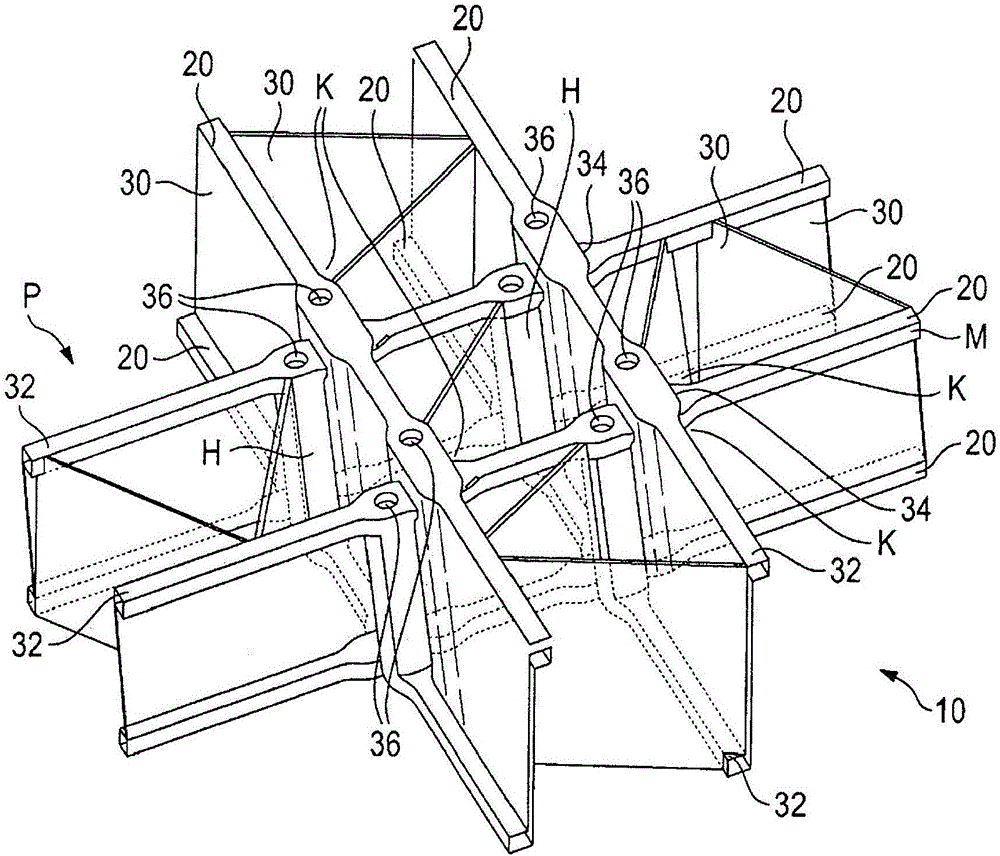

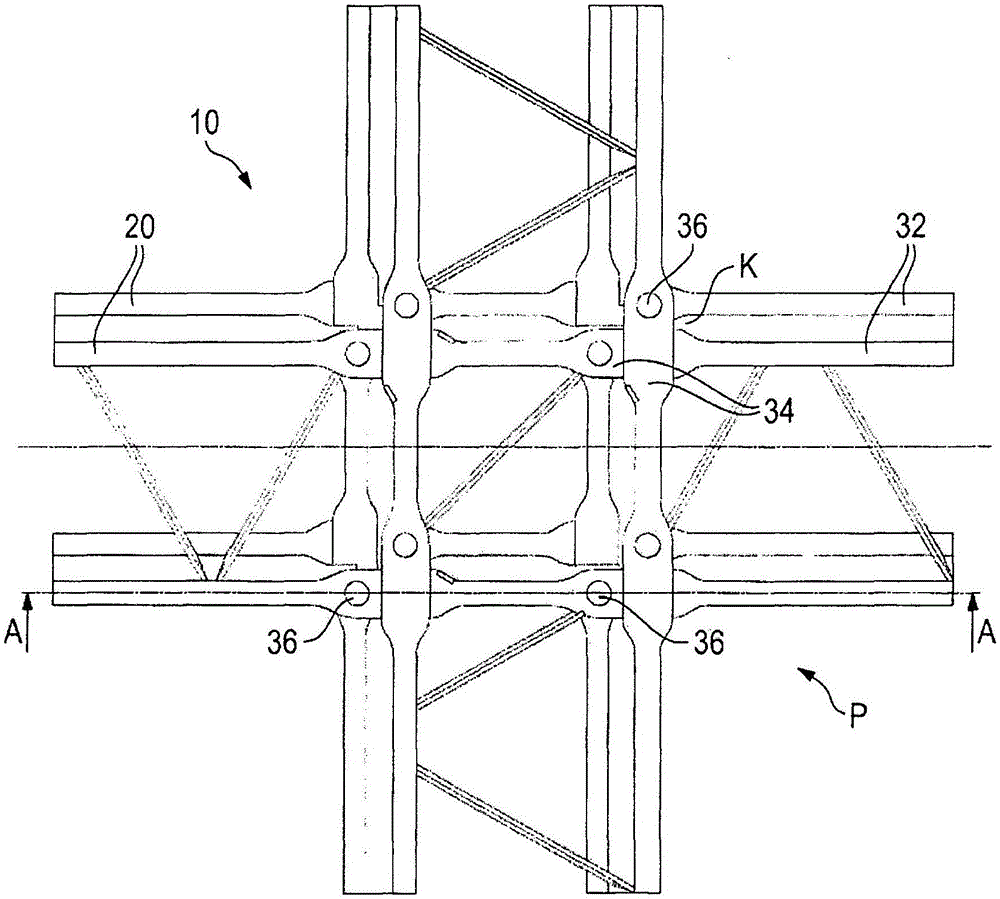

[0065] figure 1 The basic frame of the fiber composite component 10 according to the invention is shown without surrounding material, which is obtained by the method according to the invention for producing the fiber composite component 10 .

[0066] in use for manufacturing figure 1 In the production method of the fiber composite material component 10 shown, the fiber bundles 20 are firstly spatially arranged in the form of a profile P here.

[0067] The profile P here comprises four fiber bundles 20 with fibers 25 arranged approximately in parallel. A plurality of support devices 30 are arranged between the fiber bundles 20 .

[0068] The fiber bundle 20 and the support device 30 are connected to one another by means of a matrix M made of thermoplastic and / or thermosetting material. The support device 30 can be a component of the matrix M in this case.

[0069] The finished fiber composite component 10 thus comprises fiber bundles 20 and a matrix M. Here, the fiber bund...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com