Separable combination-type full-amplitude photovoltaic power generation tile

A photovoltaic power generation and combined technology, which is applied in the direction of photovoltaic power generation, photovoltaic modules, photovoltaic module support structures, etc., can solve the problems of poor bonding and sealing performance between silica gel and tiles, damage to tiles or photovoltaic modules, and high manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

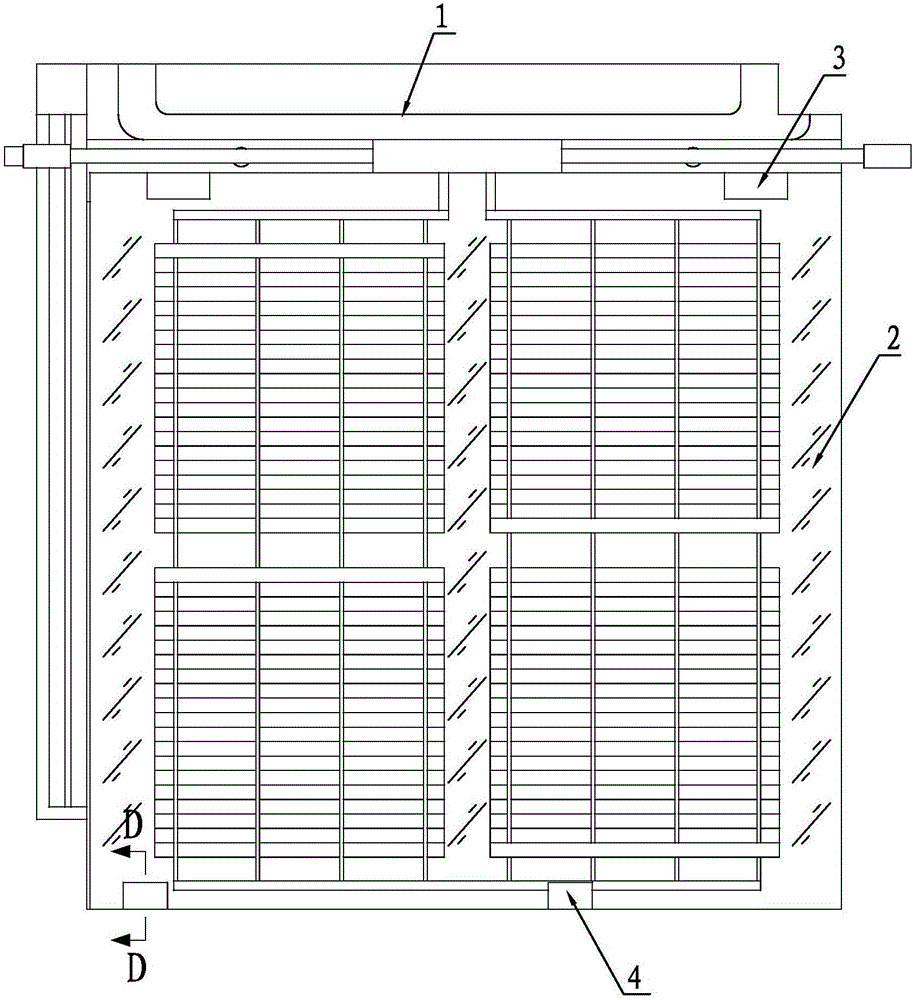

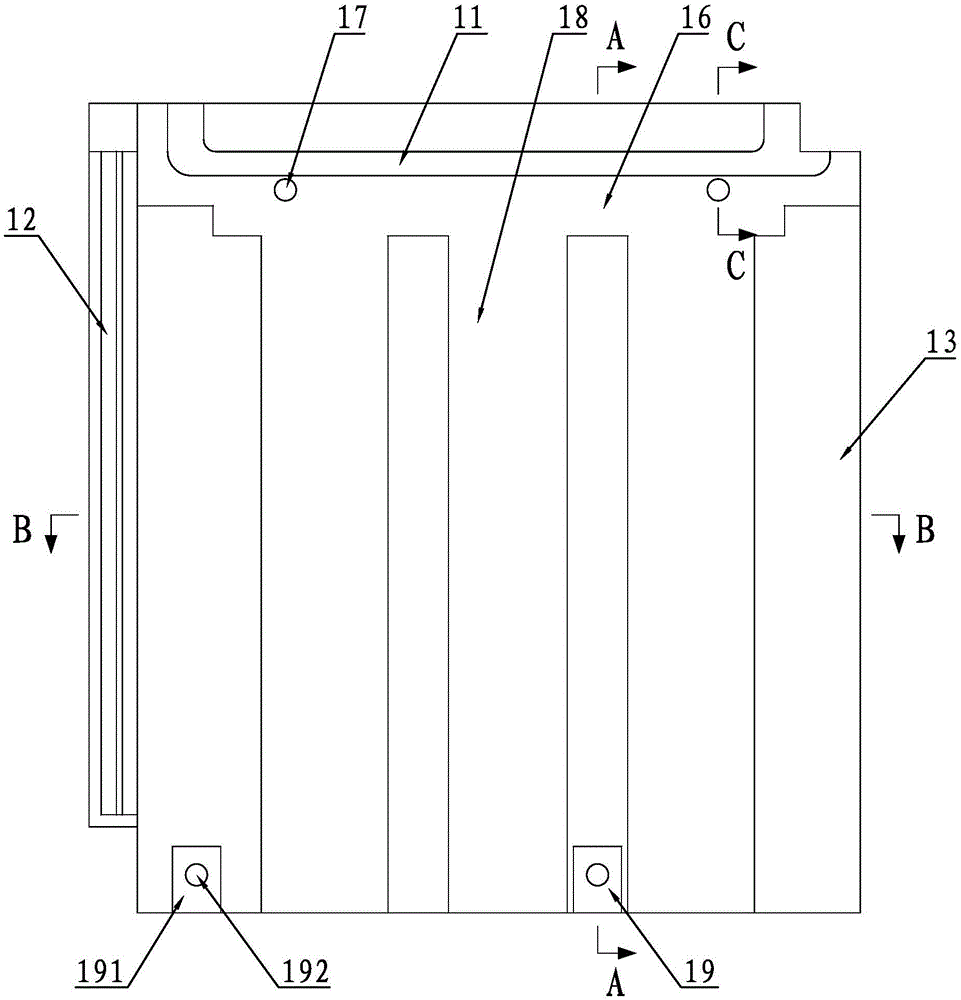

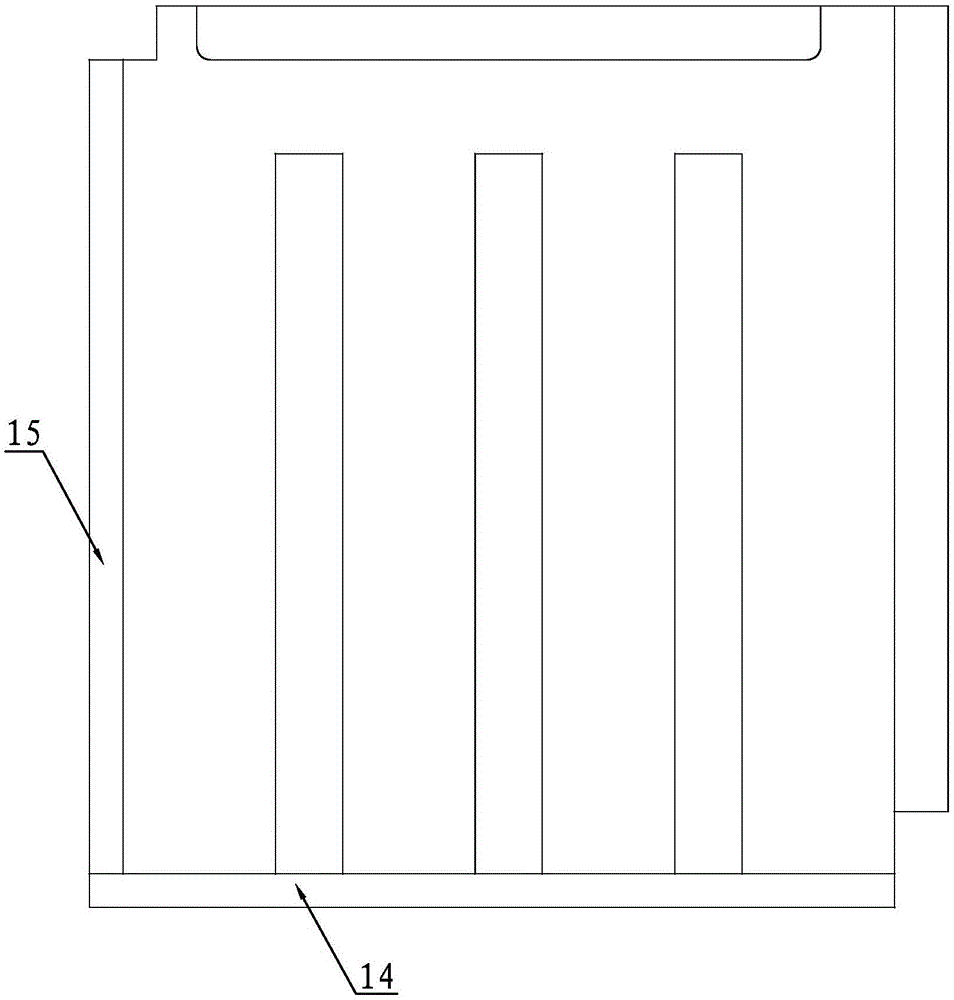

[0037] Example 1: A split combined full width photovoltaic power generation tile, such as Figure 1 to Figure 11As shown, it includes a tile body 1, a photovoltaic module 2, a heat dissipation fixing plate 3 and at least one supporting buckle 4. On the sunny surface of the tile body 1, a hanging tile convex body 11, an engaging structure 12 and a component mounting surface 13 are provided. The body 11 is arranged on the top of the sun-facing surface of the tile body 1, the engaging structure 12 is arranged on the left side of the tile body 1, and the rest of the sun-facing surface of the tile body 1 is the module installation surface 13, and the photovoltaic module 2 is installed on the module installation surface 13, At the bottom of the backside of the tile body 1, a tile hanging claw 14 corresponding to the tile hanging body 11 is provided, and on the backside of the right edge of the tile body 1, there is an engaging convex body 15 that is compatible with the engaging struc...

Embodiment 2

[0038] Embodiment 2: The difference with Embodiment 1 is that, as Figure 12 As shown, four material-saving grooves 34 are symmetrically opened on the board body 31 at the non-contact position with the junction box 22 .

Embodiment 3

[0039] Embodiment 3: The difference from Embodiment 1 and Embodiment 2 is that an elastic pad is provided between the contact surface of the heat dissipation fixing plate 3 and the solar cell panel 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com