Milk filling machine lifting device

A lifting device and filling machine technology, applied in packaging, bottle filling, liquid bottling, etc., can solve the problems of wear, easy deviation and damage of the lifting rod sliding sleeve and the bottle tray rod sleeve, so as to achieve anti-slip and Excellent anti-oxidation performance, simple and reasonable structure design, and the effect of increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

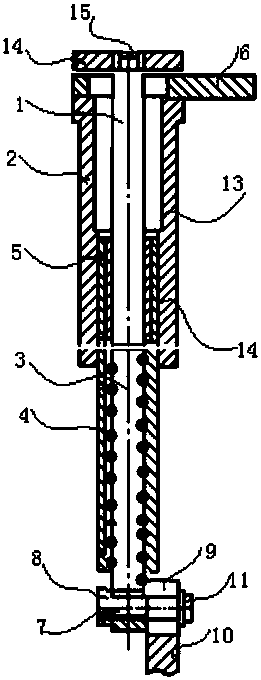

[0012] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

[0013] Such as figure 1 As shown, a milk filling machine lifting device includes a bottle tray rod 1, a bottle tray rod cover 2, a lift rod 3, a spring 4, a lift rod sliding sleeve 5, a pin shaft 7, a roller 9, a lift cam 10, Guide block 11, track 12 and track groove 13; The top of described bottle tray bar 1 is arranged on the outer surface of described bottle tray bar 1 in fixed plate 6 and is provided with bottle tray bar cover 2, and described bottle tray bar A track groove 13 is provided in the rod cover 2, and a lifting rod 3 is arranged under the bottle tray rod 1 and is adapted to it. The outer edge of the lifting rod 3 is provided with a spring 4, and the lifting rod 3, the spring 4 Set in the lifting rod sliding sleeve 5, the two sides of the lifting rod sliding sleeve 5 are provided with rails 12, the lifting rod sliding sleeve 5 moves verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com