Frequency conversion drive control system and control method based on electrolytic capacitor inverter

A drive control, electrolytic capacitor technology, applied in the direction of electronic commutation motor control, control system, motor control, etc., can solve the problems of introducing switching loss, large temperature influence, limited service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only for explaining the present invention, and are not intended to limit the scope of the present invention.

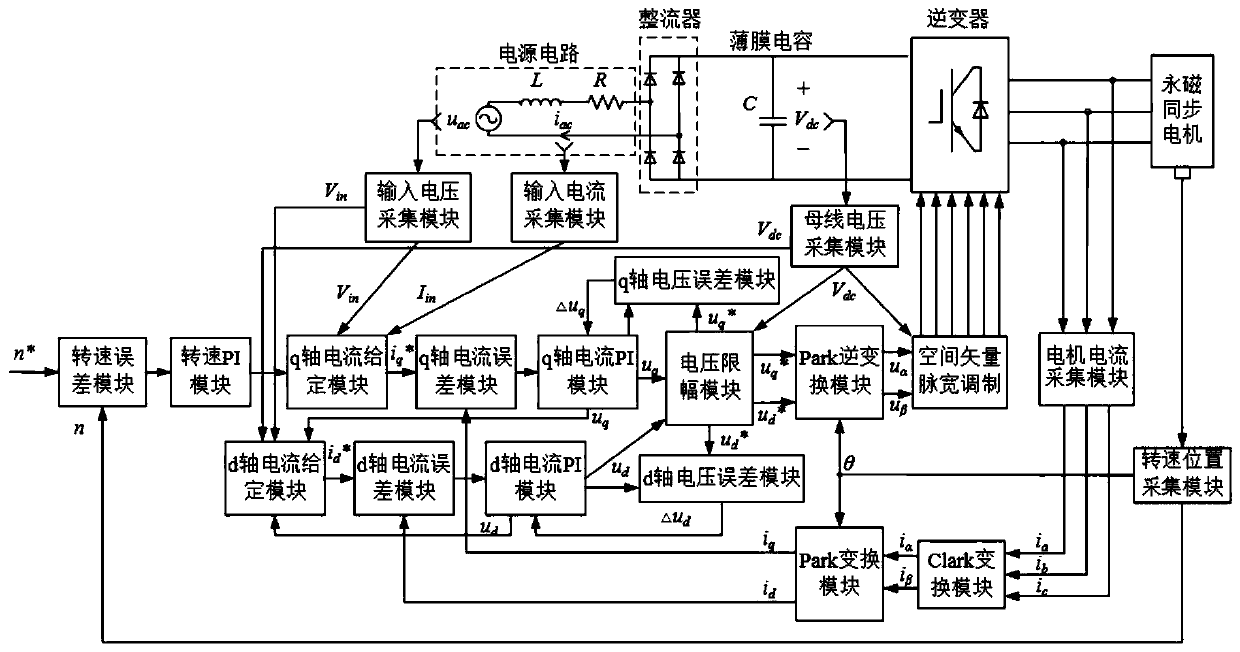

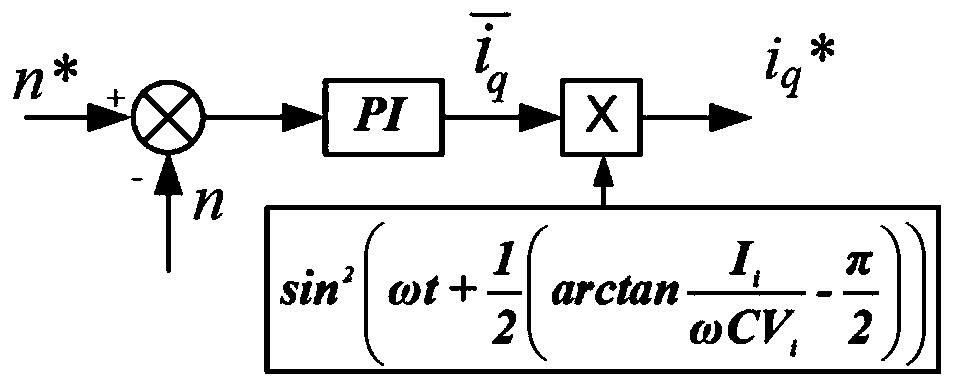

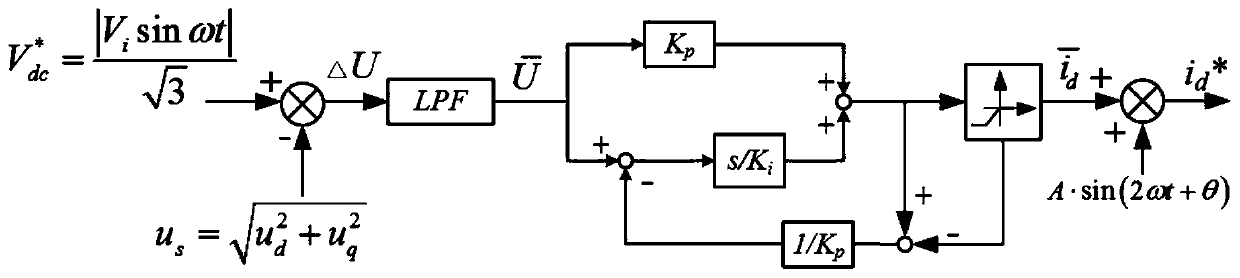

[0087] The invention discloses an electrolytic capacitor AC variable frequency drive control system, figure 1 It is a structural block diagram of the present invention, including: a power supply circuit, a rectifier, a film capacitor, an inverter, a motor, an input voltage acquisition module, an input current acquisition module, a bus voltage acquisition module, a motor current acquisition module, a rotational speed position acquisition module, and a Clark transformation module, Park transformation module, speed error module, speed PI module, d-axis current given module, q-axis current given module, d-axis current error module, q-axis current error module, d-axis current PI module, q-axis current PI module, voltage l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com