A highly integrated electromechanical actuator with integrated design

An electromechanical actuator, integrated technology, applied in the field of electromechanical servo, to achieve the effect of short zero length, offsetting the influence of different axes, and stable power transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

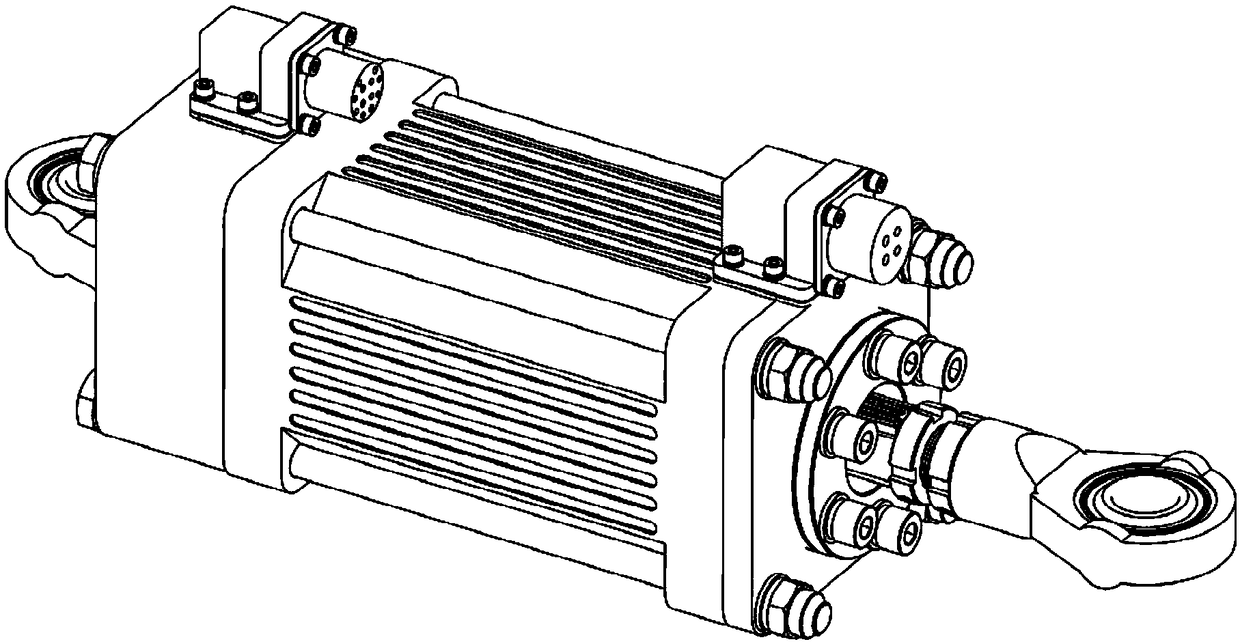

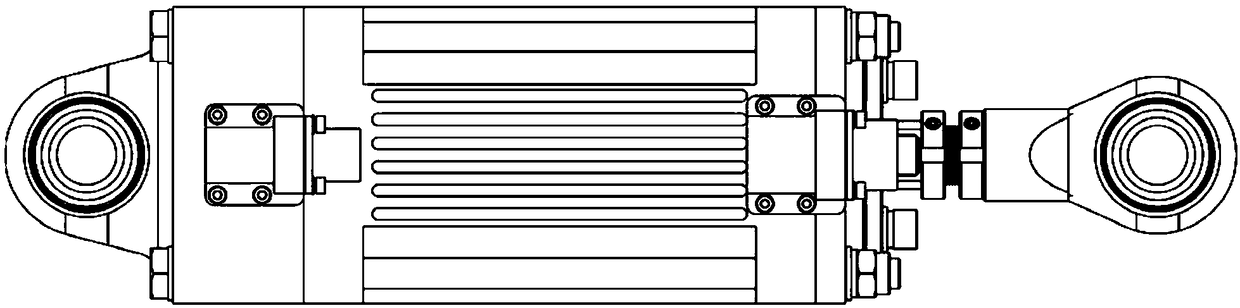

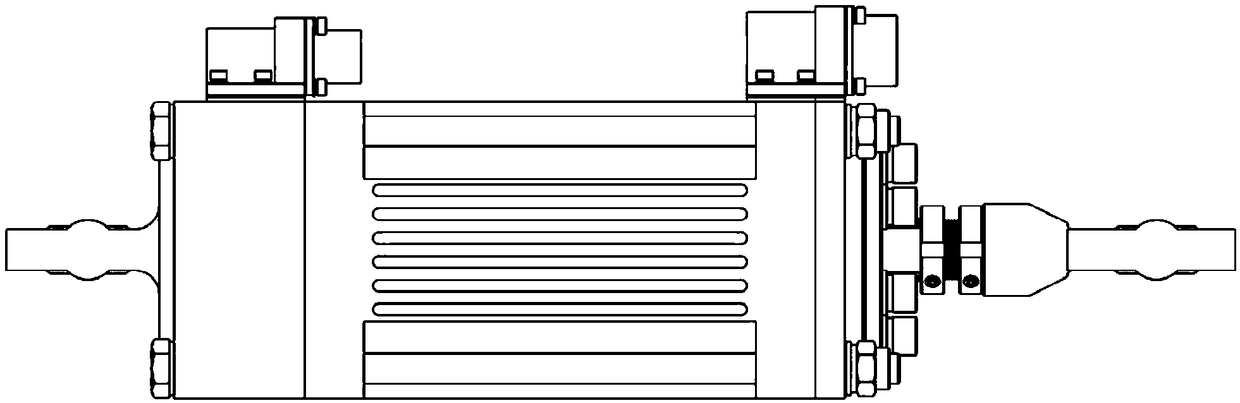

[0032] like Figure 1-7 As shown, the structural components of the present invention are composed of: long nut rotor assembly, servo motor stator assembly, rotor support and fixation assembly, screw actuating rod assembly, actuating rod support and fixing assembly, angular velocity sensor assembly, linear displacement sensor assembly, front end Lug connection components, back-end lug connection components, etc.

[0033] One end of the screw actuating rod assembly is installed with the front lug connection assembly, and the other end is matched with the long nut rotor assembly. When the long nut rotor assembly rotates at a fixed axis, the screw actuating rod assembly makes a reciprocating linear motion, and the long nut rotor assembly The outside is connected to the servo motor stator assembly through the rotor support and fixing assembly. The angular velocity sensor assembly is installed on the long nut rotor assembly to detect the angular velocity of the motor rotor. The line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com