Perpendicular lifting type entirety type double-power-source power supply device

A dual power supply, lift-type technology, applied in vertical pull isolation switchgear, switchgear components and other directions, can solve the problem of affecting the insulation performance of insulating materials, large longitudinal depth of high-voltage switchgear, and increasing the volume of the cabinet. , to reduce the difficulty of post-processing, save design space, and simplify the action mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

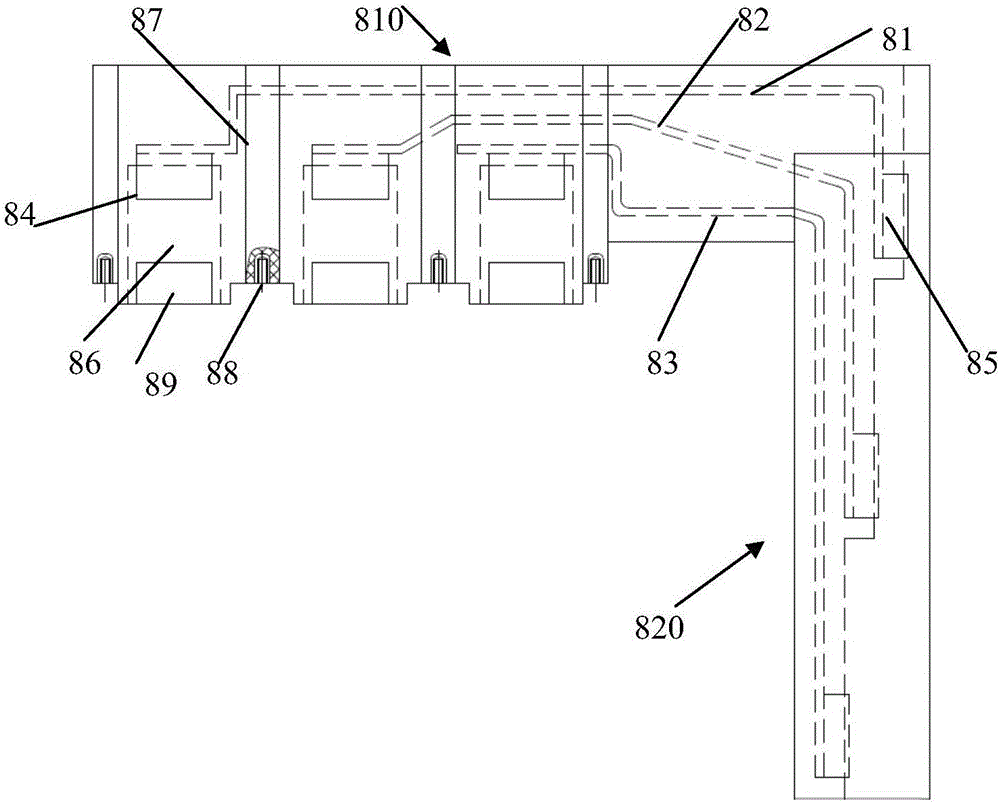

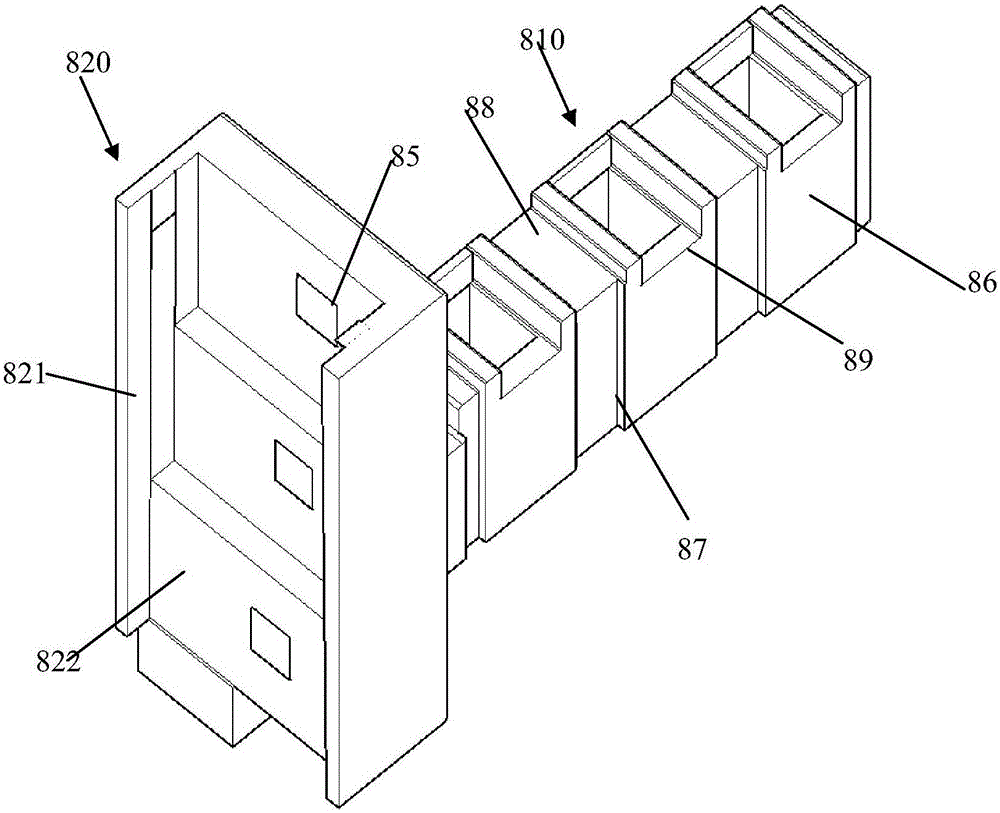

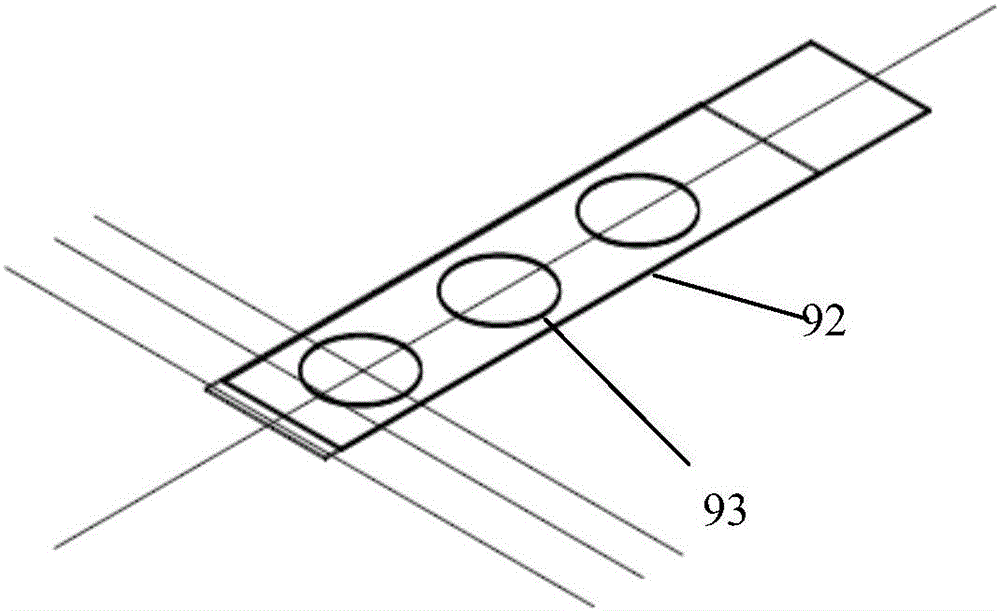

[0038] Such as Figure 1-13 As shown, a vertical lift type integral dual power supply device of the present invention includes a bracket 1 with a vertical beam 11 in the middle, corresponding to two busbar integrated insulating contact boxes fixed on both sides of the top of the bracket, set There are two lifting mechanisms on both sides of the support, which are arranged on the supporting plate of the lifting mechanism and carry a plurality of side outlet poles 70 and handcarts of the actuators, move the open and close high-voltage insulation valves, and are used to realize two Two sets of mechanical interlocking mechanisms interlocked by two actuators; the busbar integrated insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com