Integrated watertight OLED flat light source and preparation method therefor

A flat-panel light source and watertight technology, applied in semiconductor/solid-state device manufacturing, organic light-emitting device manufacturing/processing, electric solid-state devices, etc., can solve the problems of abnormal liquid sensitivity, damage and scrapping, and limit the wide application of optical lighting, etc., to achieve simple operation , easy to use, and easy to promote widely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

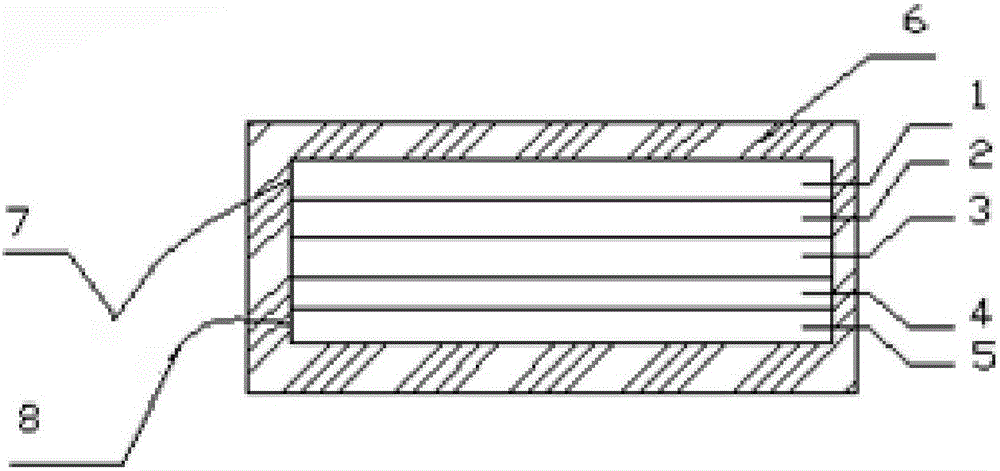

[0021] Example: such as figure 1 , figure 2 As shown, the integrated watertight OLED flat light source is composed of a cathode glass substrate layer 1, an electron transport layer 2, a light emission layer 3, a hole transport layer 4, an anode conductive substrate 5, a solid packaging colloid 6, a negative electrode wire 7, and a positive electrode wire 8. The cathode glass substrate layer 1, the electron transport layer 2, the light emitting layer 3, the hole transport layer 4, and the anode conductive substrate 5 are sequentially stacked together from top to bottom; 2. The light emitting layer 3, the hole transport layer 4, and the anode conductive substrate 5 are fully covered and wrapped; the cathode glass substrate layer 1 is connected to the negative wire 7; the anode conductive substrate 5 is connected to the positive wire 8. The integrated watertight OLED panel light source has positive and negative poles, and the positive pole wire 8 and the negative pole wire 7 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com