Low-dimensional tin halide perovskite, preparation method thereof and application of perovskite

A halide perovskite and tin source compound technology, which is applied in semiconductor/solid-state device manufacturing, photovoltaic power generation, electrical components, etc., can solve the problems of battery inoperability, battery device efficiency decay, etc., and achieve good visible light absorption properties, high Effects on air stability and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

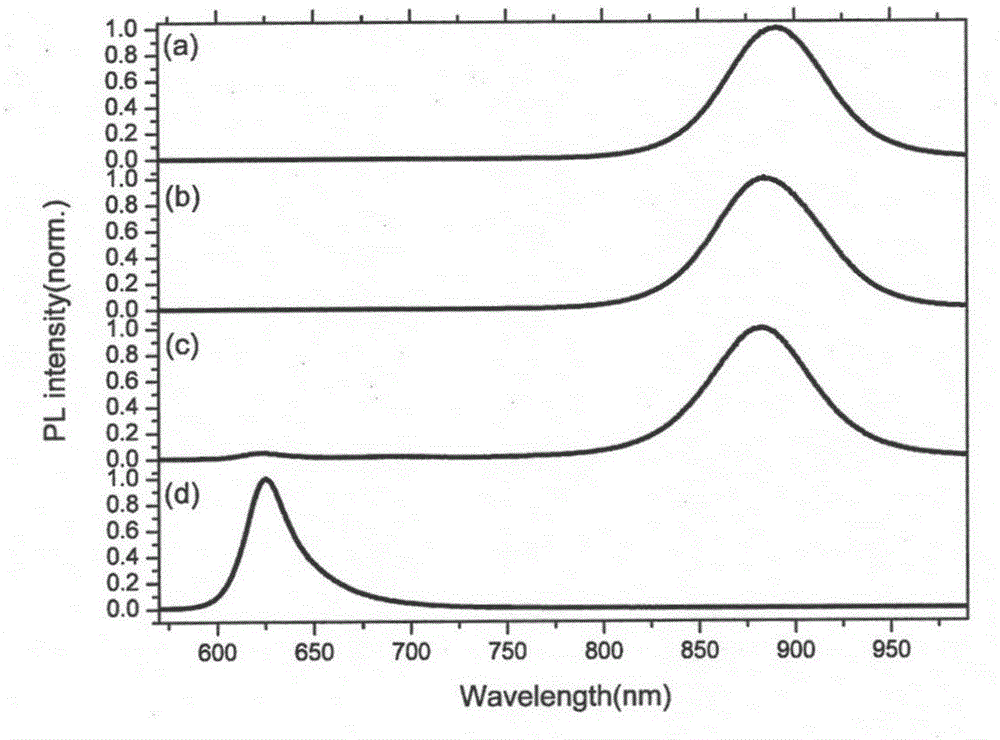

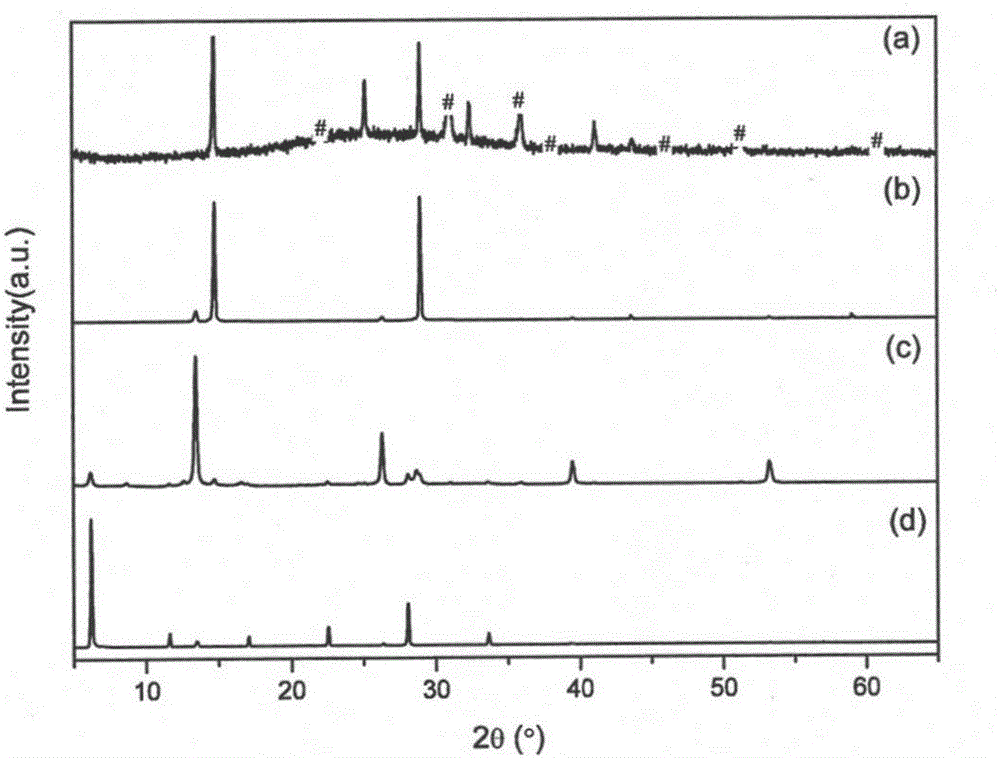

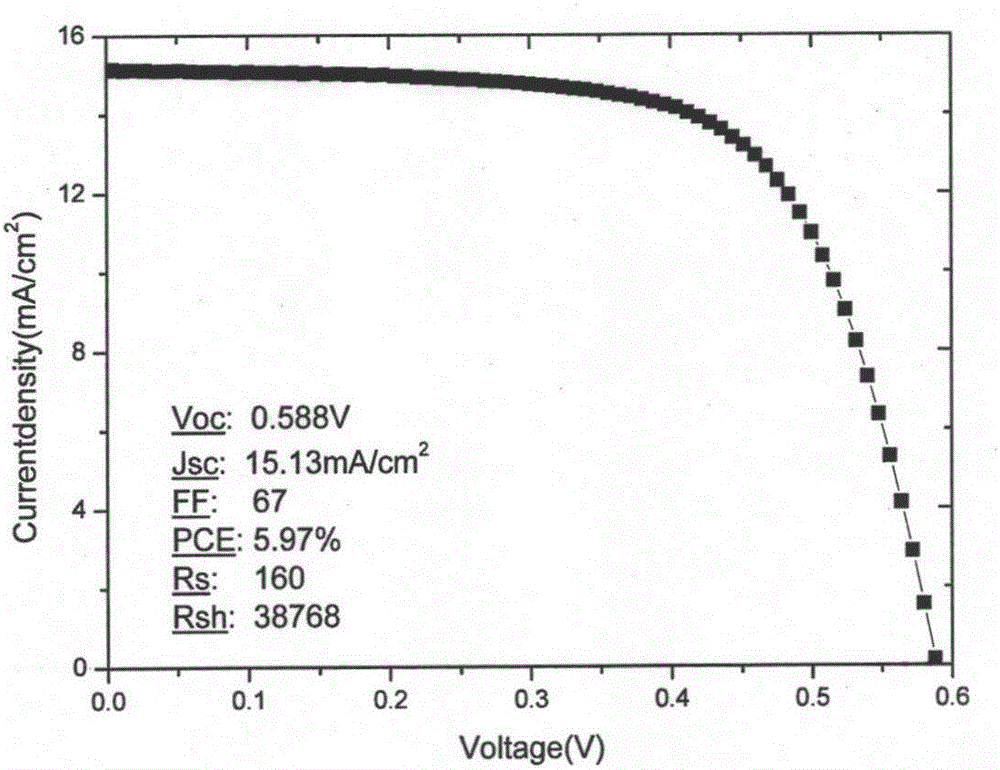

[0054] When x=0.2, (PEA) 0.2 (FA) 0.8 SnI 3 Film preparation method:

[0055] Weigh 372.5 mg (1 mmol) of stannous iodide, 137.6 mg (0.8 mmol) of formamidine hydroiodide, and 50 mg (0.2 mmol) of phenethylamine hydroiodide into a 4 mL reagent bottle, then measure 800 μL DMF and 200 μL DMSO was added to the bottle as solvent. After stirring until the solute was completely dissolved in the above solvent, 15.7 mg (0.1 mmol) of stannous fluoride was added as a reducing agent, and heated and stirred at 70° C. for 1 h to obtain a precursor solution A. After the precursor solution A was cooled to room temperature, it was filtered with a 0.22 μm pore size polytetrafluoroethylene syringe filter to obtain the precursor solution B. Take 120 μL of precursor solution B and add it dropwise on the nickel oxide substrate for spin coating. The spin coating is divided into two processes, first at 1000 rpm for 10 s, then at 5000 rpm for 30 s, the whole process is 40 s, and 600 μL of toluene is...

Embodiment 2

[0058] When x=0.4, (PEA) 0.4 (FA) 0.6 SnI 3 Film preparation method:

[0059] Weigh 372.5 mg (1 mmol) of stannous iodide, 103.2 mg (0.6 mmol) of formamidine hydroiodide, and 99.6 mg (0.4 mmol) of phenethylamine hydroiodide into a 4 mL reagent bottle, then measure 800 μL of DMF and 200 μL DMSO was added to the bottle as solvent. After stirring until the solute was completely dissolved in the above solvent, 15.7 mg (0.1 mmol) of stannous fluoride was added as a reducing agent, and heated and stirred at 70° C. for 1 h to obtain a precursor solution A. After the precursor solution A was cooled to room temperature, it was filtered with a 0.22 μm pore size polytetrafluoroethylene syringe filter to obtain the precursor solution B. Take 120 μL of precursor solution B and add it dropwise on the nickel oxide substrate for spin coating. The spin coating is divided into two processes, first at 1000 rpm for 10 s, then at 5000 rpm for 30 s, the whole process is 40 s, and 600 μL of tolue...

Embodiment 3

[0062] When x=1, (PEA) 2 SnI 4 Film preparation method:

[0063] Weigh 372.5 mg (1 mmol) of stannous iodide and 249 mg (1 mmol) of phenethylamine hydroiodide into a 4 mL reagent bottle, then measure 800 μL of DMF and 200 μL of DMSO as solvents and add into the bottle. After stirring until the solute was completely dissolved in the above solvent, 15.7 mg (0.1 mmol) of stannous fluoride was added as a reducing agent, and heated and stirred at 70° C. for 1 h to obtain a precursor solution A. After the precursor solution A was cooled to room temperature, it was filtered with a 0.22 μm pore size polytetrafluoroethylene syringe filter to obtain the precursor solution B. Take 120 μL of precursor solution B and add it dropwise on the nickel oxide substrate for spin coating. The spin coating is divided into two processes, first at 1000 rpm for 10 s, then at 5000 rpm for 30 s, the whole process is 40 s, and 600 μL of toluene is added dropwise at about 35 s. After spin coating, anneal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com