Crane wheel load testing device and method

A testing device and a crane technology, applied in measuring devices, force/torque/work measuring instruments, measurement of changes in magnetic properties of materials caused by applied stress, etc., can solve the difficulties of accurate measurement or theoretical calculation, and cannot meet Optimal performance and lightweight requirements of hoisting machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

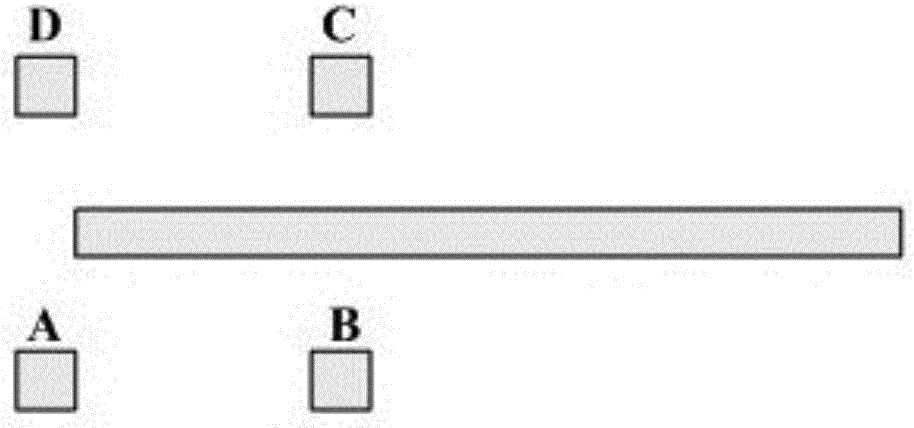

[0091] Embodiment 1. refer to figure 1 , a crane wheel pressure test device:

[0092] It includes a probe, the probe is a magnetic stress sensor, and the magnetic stress sensor includes a magnetized coil current and an anisotropic output coil for extracting electrical signals of the anisotropic effect of the magnetic properties of the measured point;

[0093] The device is also provided with an oscillating circuit, and the oscillating circuit is connected with the magnetizing coil current through the amplifying circuit; the anisotropic output coil is connected to the bridge rectifying circuit through the amplifying circuit, and the magnetizing coil current is also connected with the bridge rectifying circuit The bridge rectifier circuit is connected to the signal acquisition and processing circuit; the other end of the signal acquisition and processing circuit is also connected to a data acquisition module, and the data acquisition module is connected to the computer system....

Embodiment 2

[0095] Embodiment 2, with reference to figure 2 , a crane wheel pressure testing method, its steps are as follows:

[0096] (1) Through calculation, the maximum wheel pressure is obtained when the boom is parallel to the track, and the overall finite element model of the crane is established according to the determined relationship between the maximum wheel pressure and the position of the boom; through classical theory and finite element analysis and calculation, it is obtained Wheel pressure distribution law: The wheel pressure distribution of each wheel of the crane is different, the wheel pressure of each wheel of the driving wheel group is nearly the same, and the wheel pressure of each wheel of the driven wheel group is approximately the same; As the hoisting weight increases, the wheel pressure of the wheel set closer to the boom is getting larger, while the wheel pressure of the farther wheel set is getting smaller and smaller;

[0097] (2) Establish a strain-wheel p...

Embodiment 3

[0118] Embodiment 3, MQ12-33 type gantry crane maximum wheel pressure measurement method experiment:

[0119] Principle: The crane wheel is the only part that transmits force between the crane and the track. The force on the wheel is wheel pressure, the wheel and rail contact, and contact force is generated in the contact area. At this time, the track deforms and strains, and the track magnetic field changes accordingly. Dynamic The signal test and analysis system converts the magnetic field change into a stress value and records it, and then converts the stress into a strain according to the strain-stress relationship, and then calculates the wheel pressure according to the strain-wheel pressure model of the present invention. Its working principle is as follows Figure 11 shown.

[0120] Using the method of the present invention to measure the maximum wheel pressure of a port MQ12-33 portal crane comprises the following steps:

[0121] MQ12-33 gantry crane parameters: rated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield stress | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com