Method for converting gradient material models into additive manufacturing data formats

A gradient material, additive manufacturing technology, applied in additive processing, image data processing, electrical digital data processing, etc., can solve the problem that the additive manufacturing process cannot be directly applied, and achieve the effect of high-precision transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

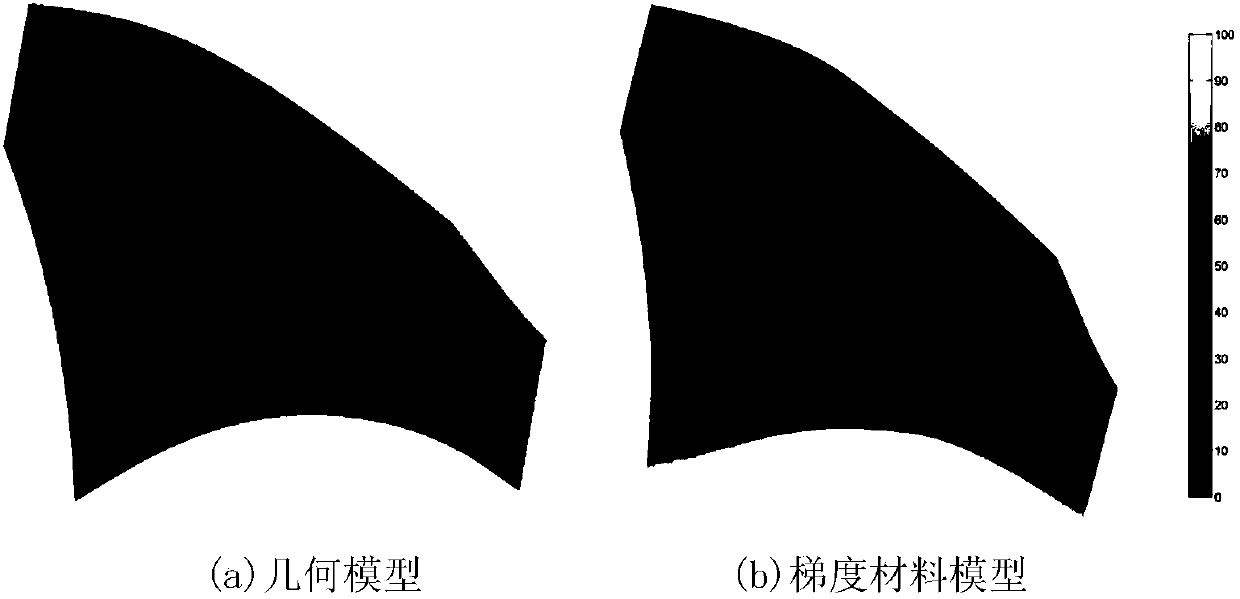

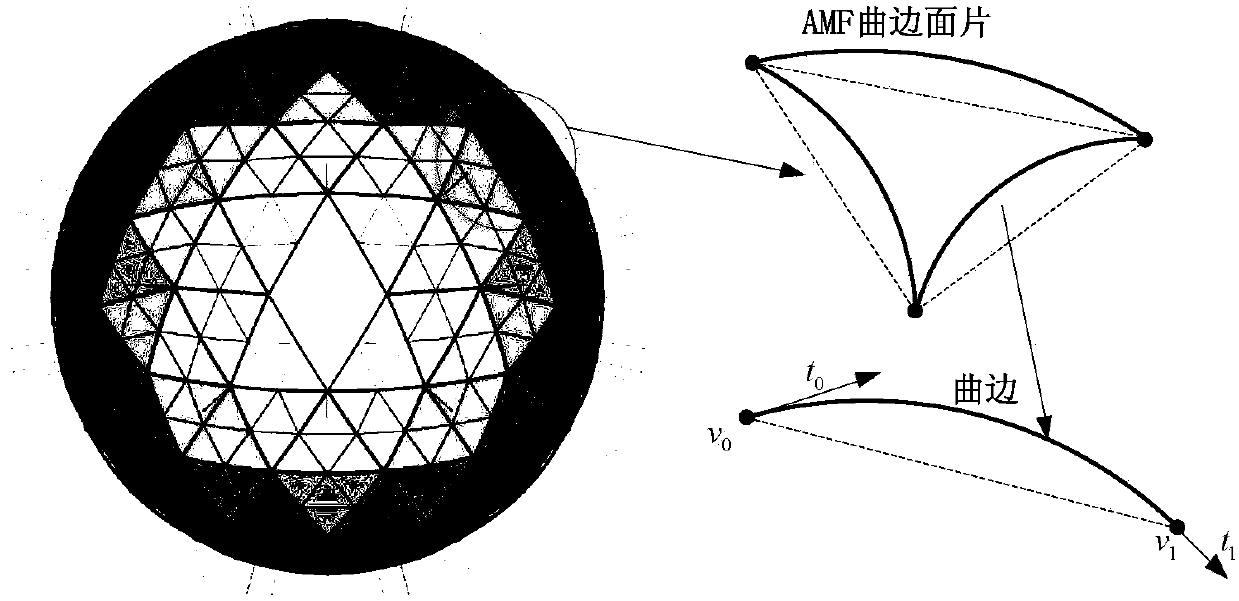

[0031] In order to realize the high-precision and high-efficiency transition from the gradient material parameterized model to the AMF format file, the present invention takes the mapping relationship between the parameter space and the physical space of the gradient material parameter model as the starting point, since the model parameter domain is in the form of cubes and squares For this type of regular area, first divide the parameter domain into tetrahedrons or triangular patches, obtain the curved tetrahedron and triangular elements suitable for AMF format representation through the mapping relationship, and then read the corresponding material, color and other information at the grid nodes , write it into the AMF file according to the standard format, and finally organize the acquired curved edge mesh units and other information in the form of XML documents to complete the transfer between the gradient material model and the additive manufacturing format file.

[0032] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com