AGC control system and method based on heating-extracting flow change

A control system and extraction steam flow technology, which is applied to controllers with specific characteristics, electric controllers, steam applications, etc., can solve problems such as large fluctuations in AGC control performance indicators of units, and weakened steam work ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

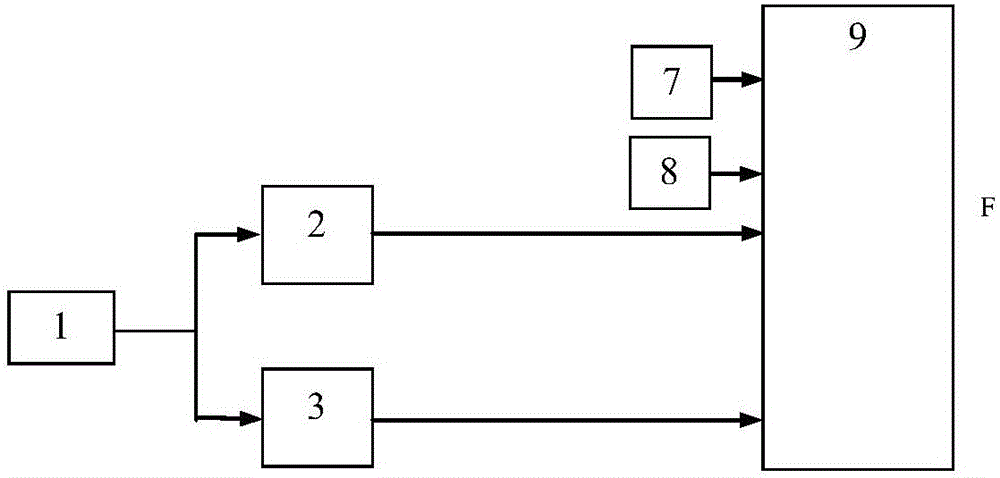

[0063] figure 1 It is a principle structure diagram of an AGC control system based on the variation of heat supply and steam extraction in the present invention.

[0064] Unit heating and extraction steam flow measuring device 1, which is used to measure the unit heating and extraction steam flow and transmit it to the processor;

[0065] the processor configured to:

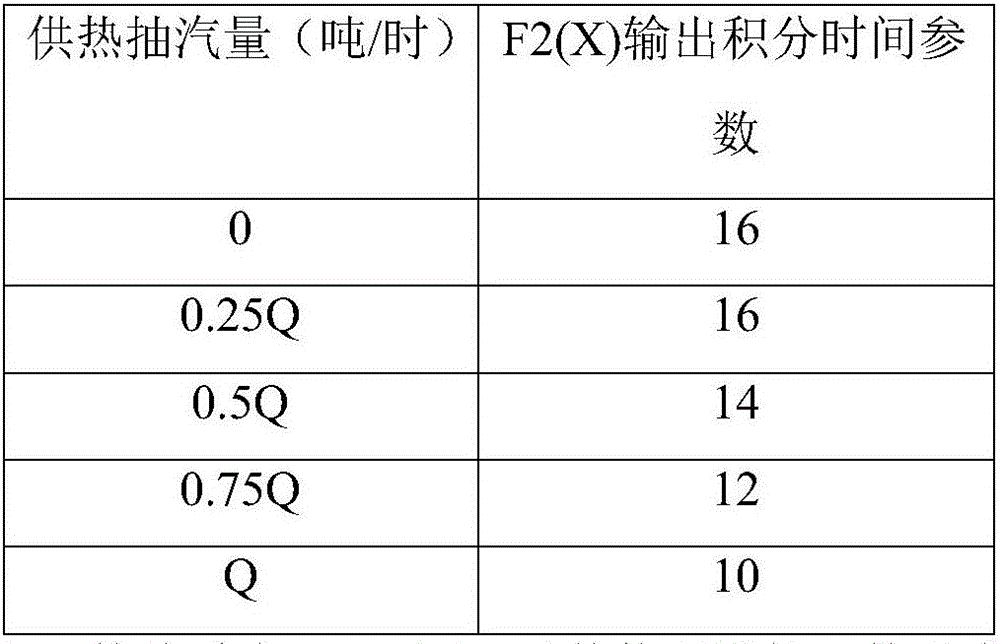

[0066] The functional relationship F1(X) between the preset proportional coefficient and the heating and extraction steam flow of the unit; and the functional relationship F2(X) between the integral time parameter and the heating and extraction steam flow of the unit; according to the functional relationship F1(X) and F2 (X), dynamically calculate the proportional coefficient and the integral time parameter of the main control PID controller and send to the main control PID controller;

[0067] Unit load real-time measuring device 8, which is used to measure the unit load in real time and transmit it to the ma...

Embodiment 1

[0085] The control method of the AGC control system based on the change of the heating and extraction steam volume of the first embodiment specifically includes the following steps:

[0086] Step (1): The unit heat supply and extraction steam flow metering device transmits the measured unit heat supply and extraction steam flow to the processor;

[0087] Step (2): The functional relationship F1(X) between the preset proportional coefficient in the processor and the heating and extraction steam flow of the unit; and the functional relationship F2(X) between the integral time parameter and the heating and extraction steam flow of the unit; according to the function Relational formulas F1(X) and F2(X), dynamically calculate the proportional coefficient and integral time parameters of the main control PID controller and send them to the main control PID controller;

[0088] Step (3): The unit load real-time measurement device measures the unit load in real time and transmits it to...

Embodiment 2

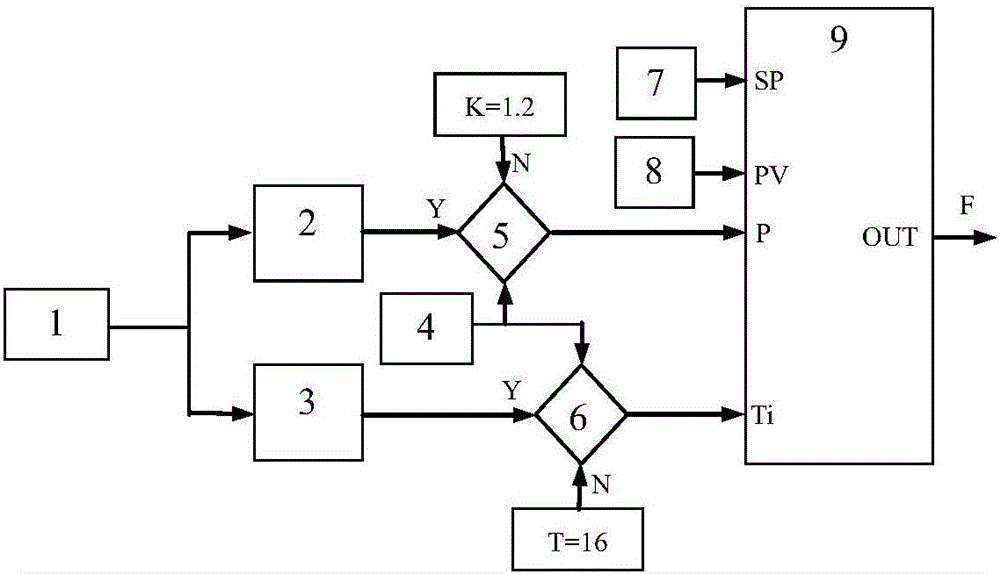

[0096] figure 2 It is another schematic structure diagram of the AGC control system based on the variation of heating and extraction steam volume of the present invention.

[0097] A kind of AGC control system based on the variation of heat supply and steam extraction in this embodiment includes:

[0098] Unit heating and extraction steam flow measuring device 1, which is used to measure the unit heating and extraction steam flow and transmit it to the processor;

[0099] the processor configured to:

[0100] The functional relationship F1(X) between the preset proportional coefficient and the heating and extraction steam flow of the unit; and the functional relationship F2(X) between the integral time parameter and the heating and extraction steam flow of the unit;

[0101] According to the functional relationship F1(X) and F2(X), the proportional coefficient and integral time parameters of the main control PID controller are dynamically calculated;

[0102] The processor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com