A display module and bonding method thereof

A display module and lamination technology, applied in the direction of instruments, polarizing elements, light guides, etc., can solve the problems of increasing the thickness of the display module, uneven brightness, and increased design size, and achieve narrow borders and thin design, The effect of reducing the size of the outer outline and reducing the width of the border

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

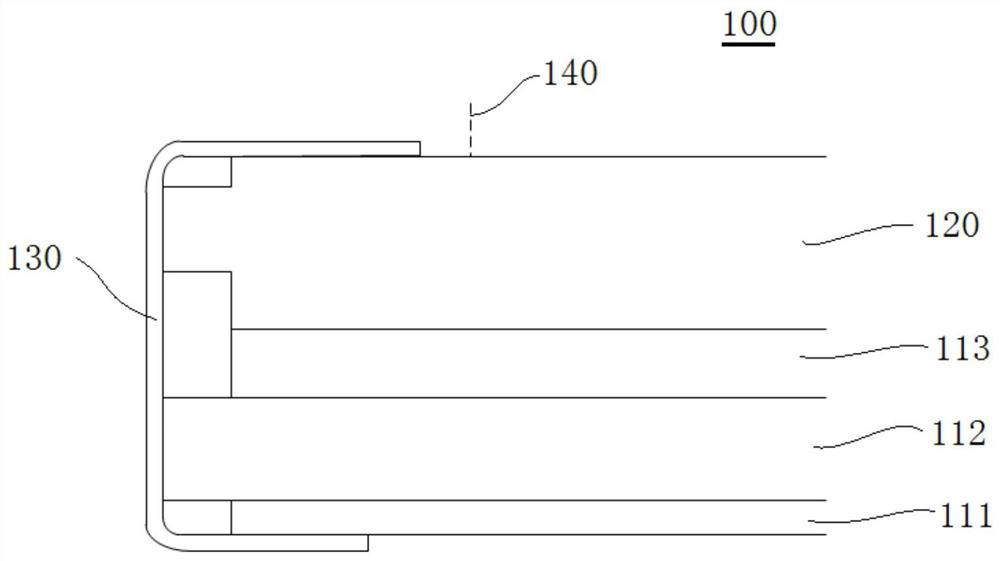

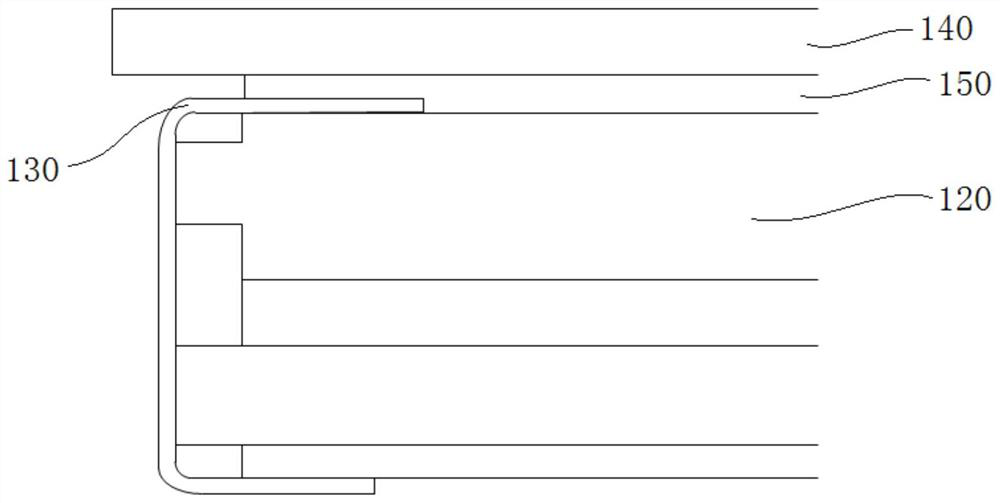

[0031] figure 2 It is a display module 100 of the present invention, which includes a backlight unit and a liquid crystal unit 120 from bottom to top. The backlight unit includes a reflective sheet 111, a light guide plate 112, and an optical film layer 113 in sequence. The liquid crystal unit 120 is arranged on the optical film. Above the layer 113, the backlight unit in this embodiment no longer contains a plastic frame, so the size of the light guide plate 112 can be enlarged, and the projection of the outer contour line of the light guide plate 112 on the liquid crystal unit 120 is the first projection line. The size of 112 can be increased to make the first projected line coincide with the outer contour line of the liquid crystal unit 120, thus increasing the distance between the outer contour line of the light guide plate 112 and the edge 140 of the effective display area of the liquid crystal unit 120, avoiding The risk of light leakage around the light guide plate 1...

Embodiment 2

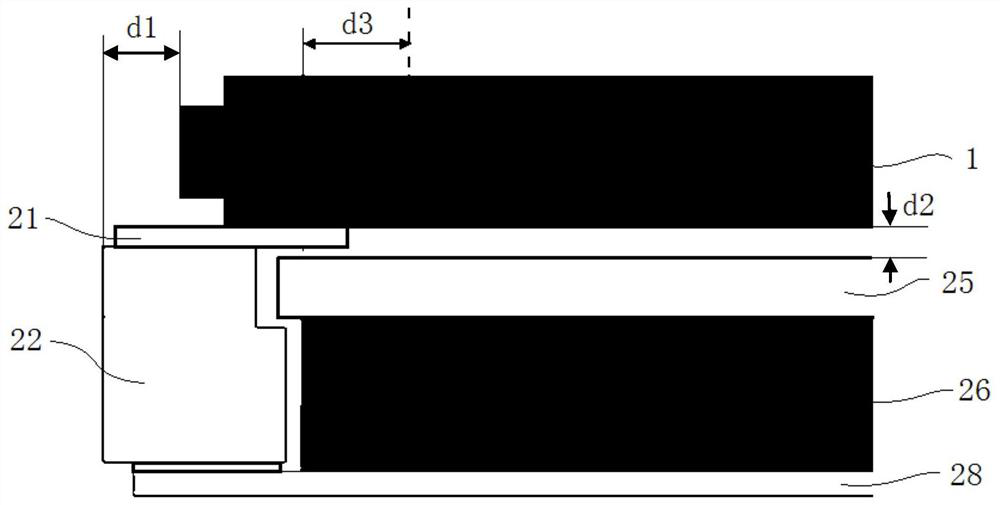

[0035] Figure 4 It is a structural schematic diagram of the display module 200 in this embodiment, which includes a backlight unit and a liquid crystal unit in sequence from bottom to top, the backlight unit includes a reflective sheet 211, a light guide plate 212, and an optical film layer 213 in turn, and the liquid crystal unit includes a first The polarizer 221, the array substrate 222, the color filter 223 and the second polarizer 224, the first polarizer 221 of the liquid crystal unit is attached to the optical film layer 213 of the backlight unit, and the backlight unit in this embodiment no longer contains Plastic frame, so the size of the light guide plate 212 can be enlarged. Preferably, the projection of the outer contour line of the light guide plate 212 on the liquid crystal cell is the first projection line, and the size of the light guide plate 212 can be increased to make the first projection line and The outer contour lines of the liquid crystal unit coincide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com