An Angle Adaptive High Precision Mirror Body Lateral Support Mechanism

A lateral support and self-adaptive technology, applied in the direction of instruments, installation, optics, etc., can solve the problems of inability to guarantee the surface shape accuracy of the mirror body, heavy weight, complex structure, etc., to achieve the best engineering feasibility, improve work quality and adaptability The effect of ensuring the accuracy of surface shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

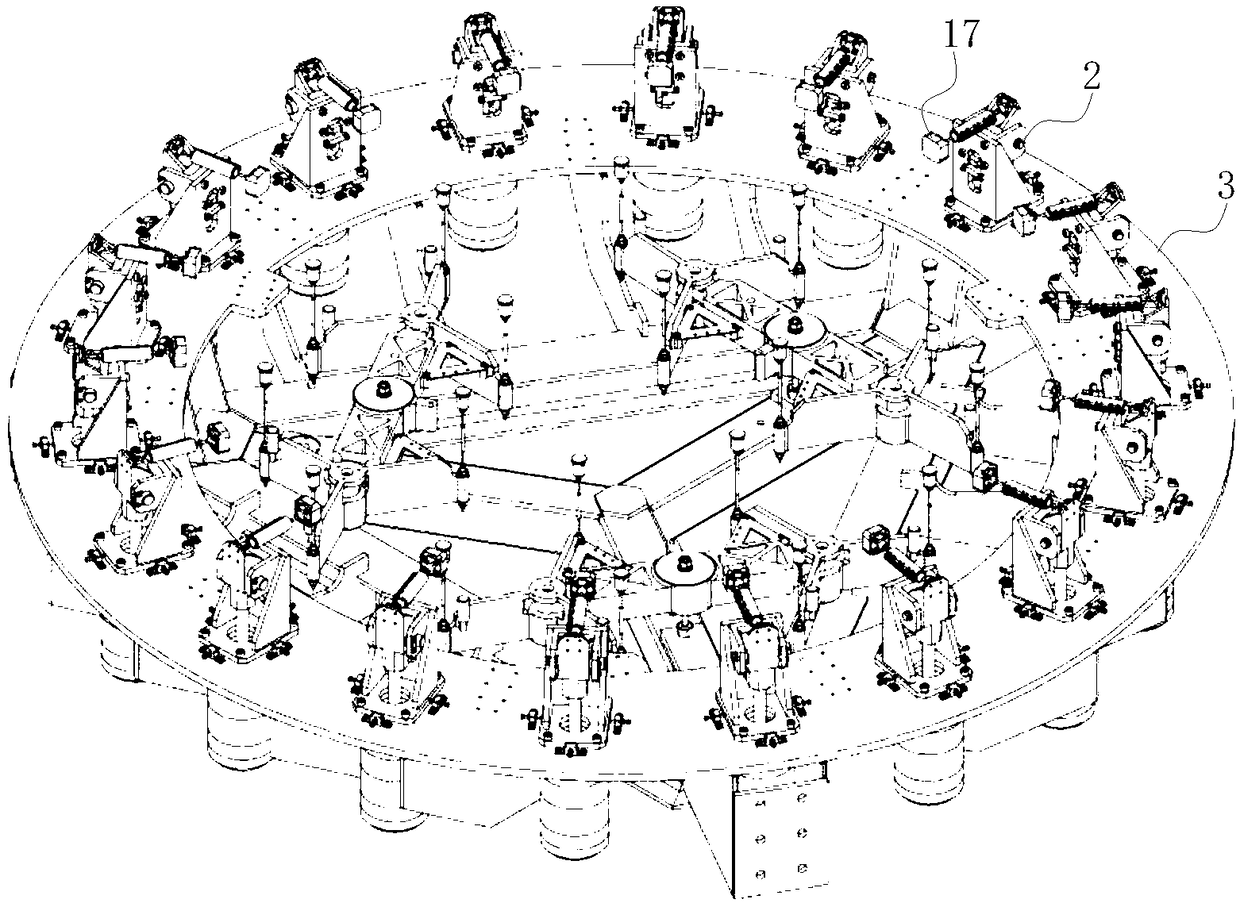

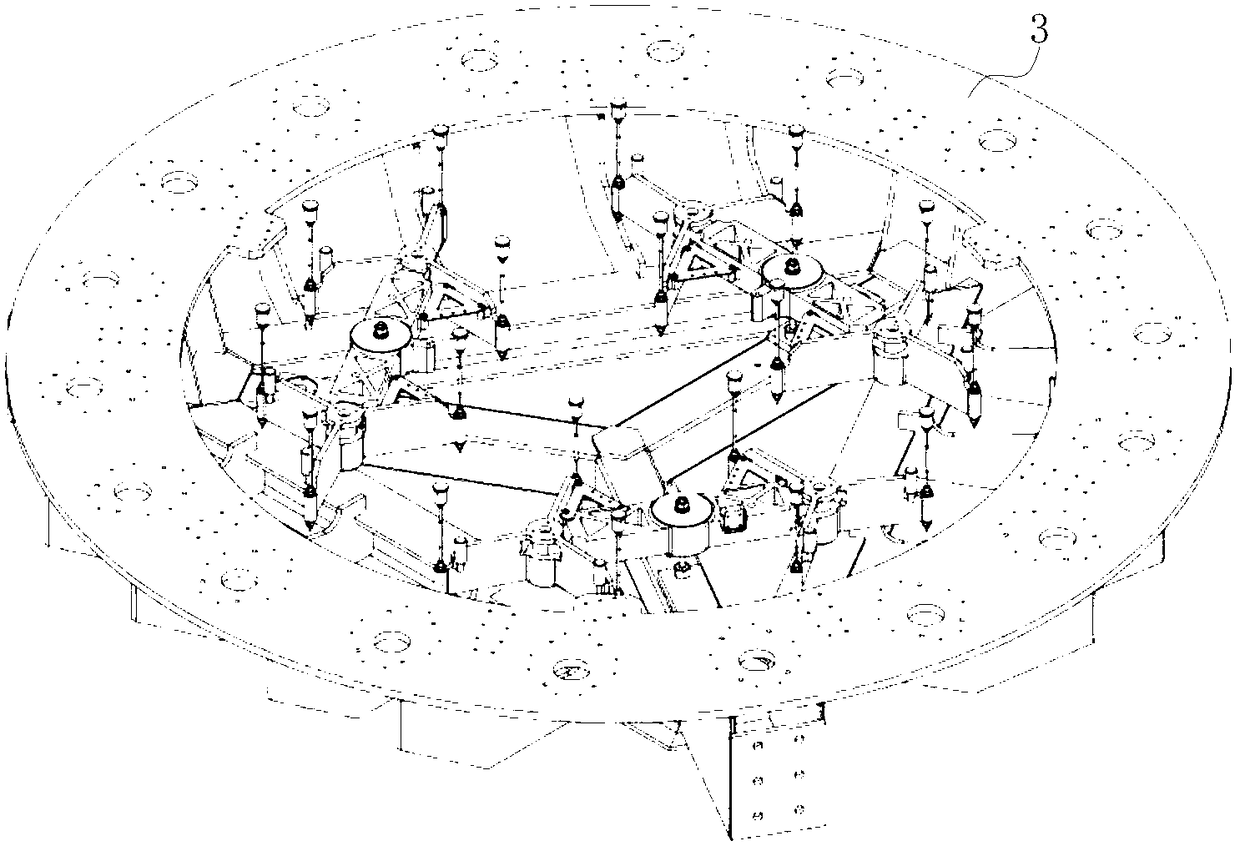

[0033] See attached figure 1 - attached Figure 5 , an angle-adaptive high-precision mirror body lateral support mechanism of the present invention comprises:

[0034] An annular support base plate 3, a plurality of axial connection holes are evenly distributed on the circumference of the support base plate 3, and multiple sets of whiffletree structures are evenly arranged at the position of the middle through hole of the support base plate 3 to contact and support the bottom surface of the mirror body 1;

[0035] A plurality of bonding blocks 17 uniformly distributed on the side wall of the mirror body 1, the bonding blocks 17 and the side wall of the mirror body 1 are bonded and fixed;

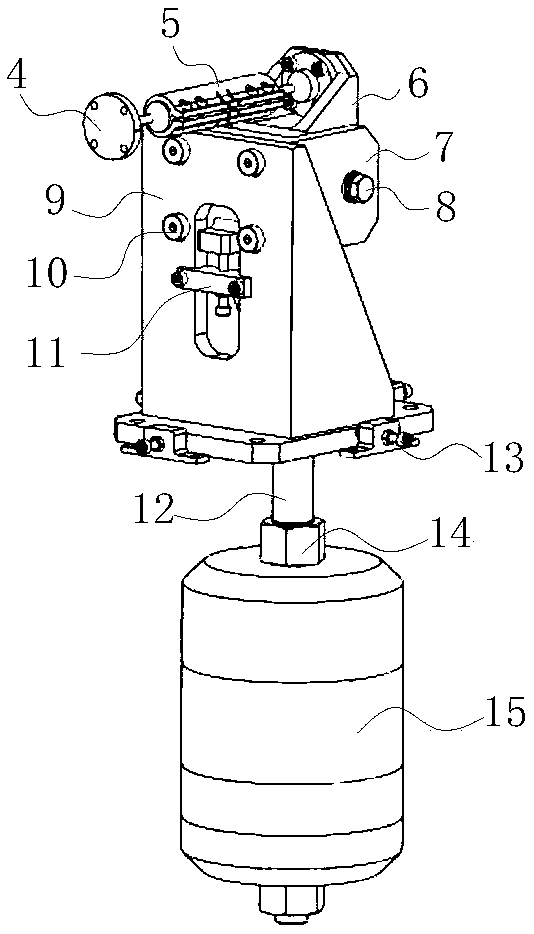

[0036] A plurality of side support mechanisms 2 evenly distributed on the circumference, each side support mechanism 2 includes a connecting rod, a lever structure 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com