Composite material stiffness coefficient nondestructive measurement method

A technology of composite materials and measurement methods, which is applied in the direction of measuring devices, analyzing materials, and using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc. It can solve problems such as inaccurate measurement results, debonding of piezoelectric sheets, and increased complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

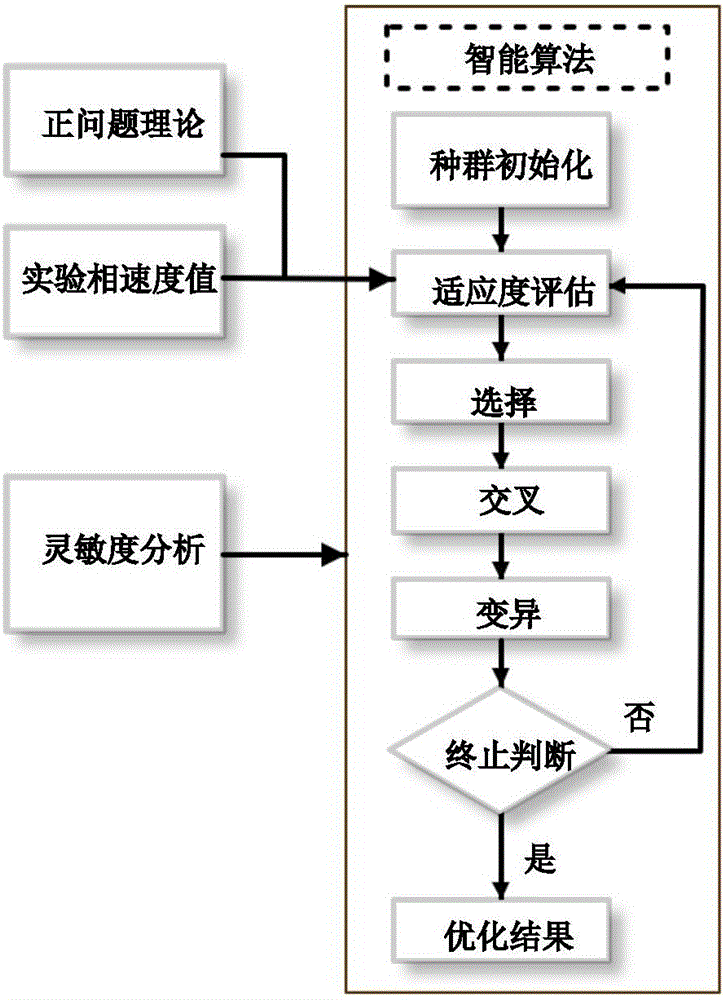

[0050] The flow chart of the non-destructive measurement method of the composite material stiffness coefficient proposed by the present invention is shown in figure 1 , including the following steps:

[0051] The first step is to model the positive problem theory:

[0052] First, it is assumed that the guided wave displacement field distribution in the composite layup is

[0053]

[0054] The coordinates x and y are the in-plane directions, and z is along the plate thickness direction; u, v and w are the displacement components in the x, y and z directions respectively; the displacement field has 12 unknown quantities, respectively u 0 , ψ x , v 0 , ψ y ,w 0 , ψ z ,φ x , χ x , φ y , χ y , φ z , χ z . The above formula represents a typical third-order plate theoretical displacement field function. Considering the stress-free boundary conditions on the upper and lower surfaces of the plate when Lamb waves propagate in the plate

[0055]

[0056] The subscrip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com