Noncontact gas leakage detection system

A gas leak detection, non-contact technology, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum for liquid tightness measurement, etc. Reduce the service life of storage tanks and other issues, and achieve the effect of controlling installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Specific embodiments of the present invention will be described in detail below.

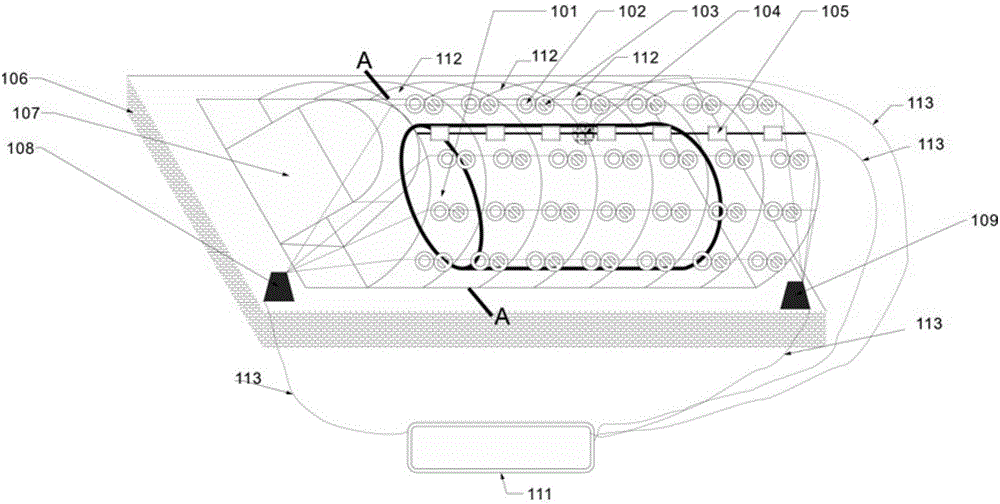

[0042] Such as Figure 1~4 As shown, a non-contact gas leak detection system includes:

[0043] support body 106,

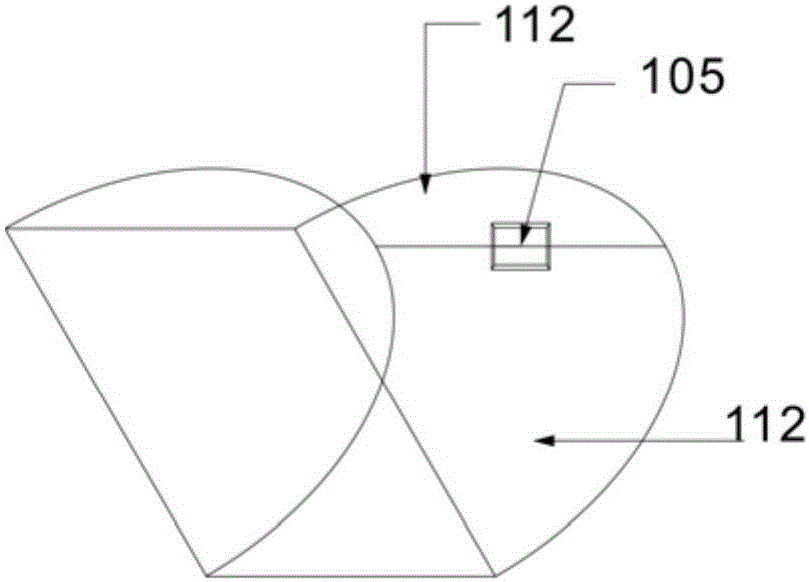

[0044] The gas isolation cover device includes multiple sets of isolation units fixed on the upper surface of the support body 106 arranged parallel to the axis of the horizontal storage tank 101, separated from the horizontal storage tank 101, and used to cover the surface of the horizontal storage tank 101 form a relatively isolated system;

[0045] A plurality of gas detection sensors 102 are arranged at equal intervals on the gas isolation cover device in a manner parallel to the axis of the gas isolation cover device, for real-time monitoring of the concentration of the target gas between the horizontal storage tank 101 and the gas isolation cover device;

[0046] A plurality of gas flow rate sensors 103 are arranged at equal intervals on the gas isolation cover devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com