Telescopic boom and crane with the telescopic boom

A telescopic boom and crane technology, applied in cranes and other directions, can solve the problems of long time, high installation cost, time-consuming and laborious, etc., and achieve the effects of convenient disassembly and assembly, control of installation cost, and easy operation of shaft penetration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

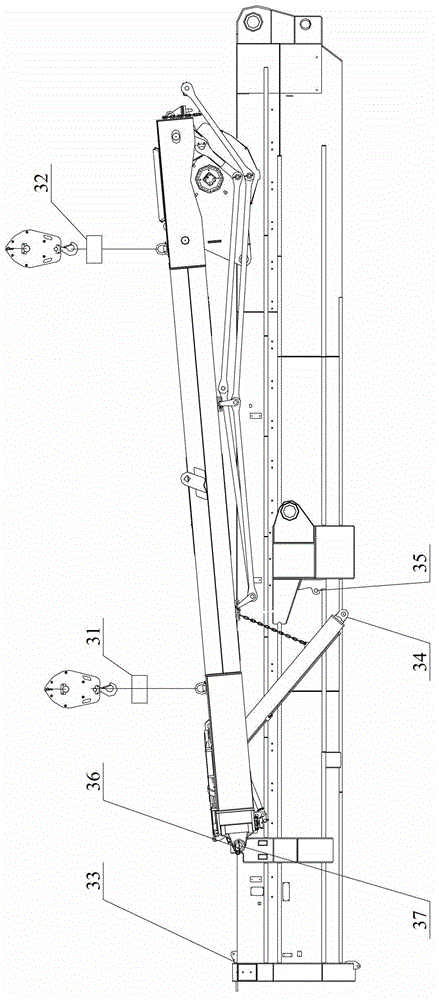

[0030] The core of the present invention is to provide a crane telescopic arm with an optimized structure, which can effectively improve the assembly efficiency of its super-lifting device through the arrangement of positioning components, and can effectively control the installation cost at the same time. The present embodiment will be described in detail below in conjunction with the accompanying drawings.

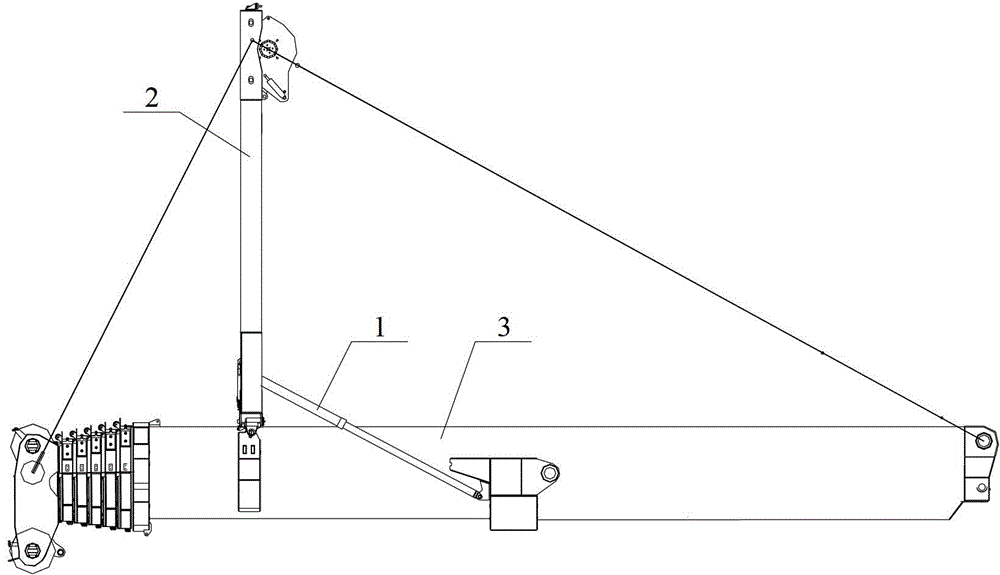

[0031] See Figure 4 , which is a schematic diagram of the overall structure of the telescopic boom of the crane described in this embodiment. This figure does not show the expanded state of the sequentially nested and connected telescopic boom sections, so as to clearly show the relative positional relationship between the positioning member and the basic boom sections in this solution.

[0032] Relatively speaking, the main hinge point hole 11 for hinged with the hinged end of the superlift device 20 is located at the front of the basic jib section 10, and is used for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com