A method for correcting test results of infrared temperature measuring equipment

A technology of infrared temperature measurement and test results, applied in the field of metallurgy, can solve problems such as difficult to measure more accurate temperature, and achieve the effect of large temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

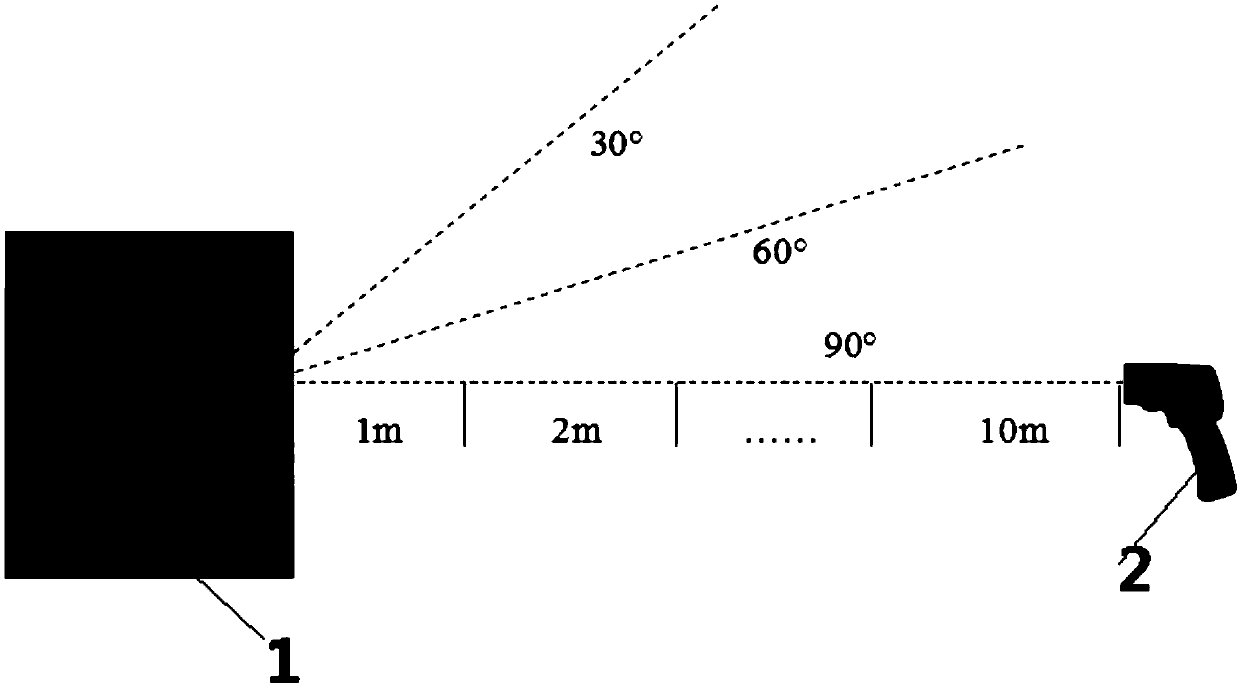

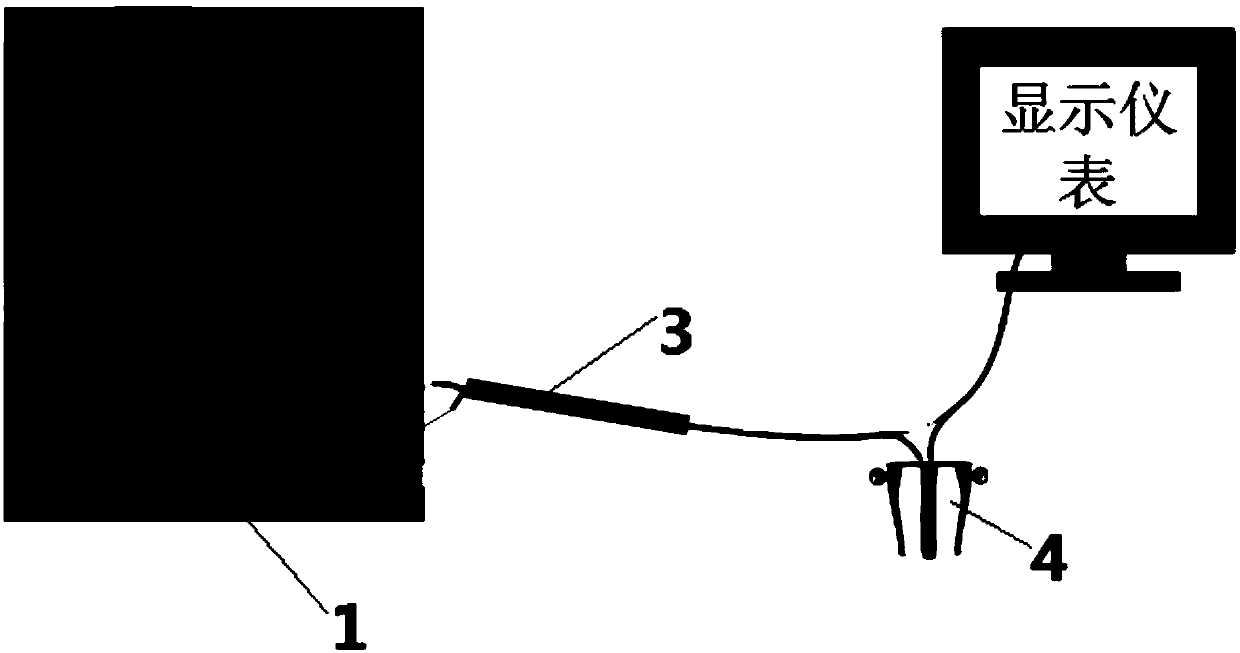

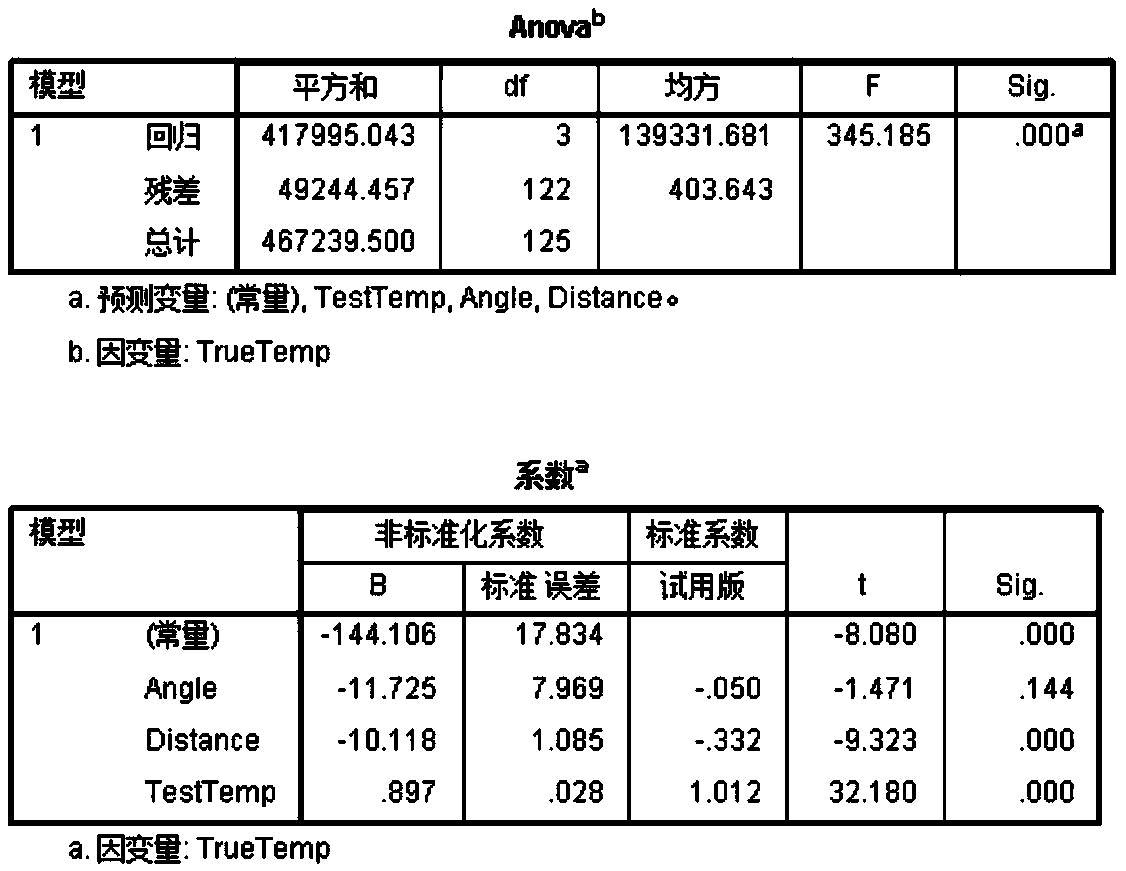

Method used

Image

Examples

Embodiment

[0058] Example: Surface temperature measurement of a 6.8t steel ingot in a special steel plant

[0059] (1) Basic information:

[0060] G15 6.8t steel ingots are poured by a steel pouring car, with 6 pieces in a plate. It is necessary to know the change of the mold temperature during the injection molding process and the cooling process to confirm the solidification state of the steel ingot and provide corresponding parameters for the numerical simulation. There are many measurement points, the time is tight and the environment is harsh, so non-contact temperature measurement should be used. The temperature measured by 3i2mSc / C2 infrared temperature gun is shown in Table 2.

[0061] Table 2. Surface temperature of 6.8t steel ingot ingot mold measured by infrared temperature measuring gun and infrared thermal imager

[0062]

[0063] (2) Application method

[0064] In fact, the temperature range of the ingot mold obtained by manual measurement with thermocouples is 100-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com