V-shaped pore plate for instant freezer

A quick-freezing machine and orifice plate technology, which is applied in applications, household appliances, household refrigeration equipment, etc., to achieve the effect of improving the single-directional impact problem, improving the heat transfer coefficient, and increasing the freezing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the operation process and creative features realized by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

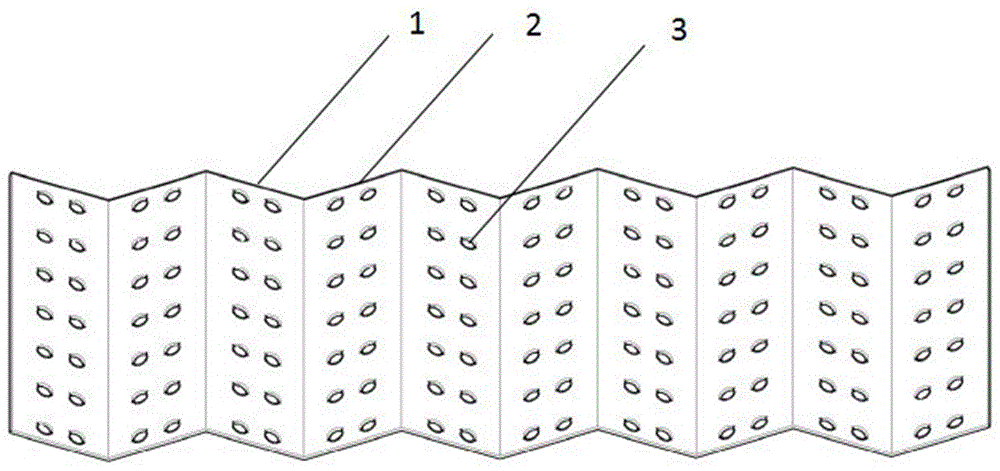

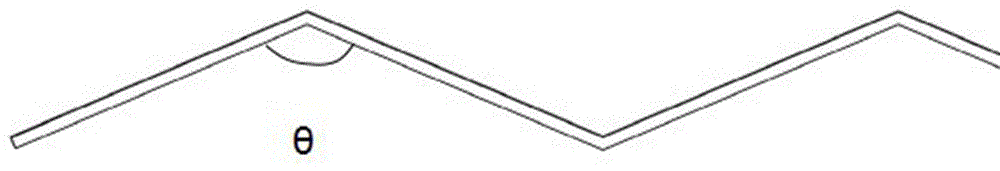

[0017] The V-shaped orifice plate for the quick-freezing machine includes the first side blowing orifice plate surface 1, the second side blowing orifice plate surface 2, and the orifice opening 3; the V-shaped orifice plate structure of the quick-freezing machine is characterized in that: the first side blowing orifice plate The plate surface 1 and the second air blowing orifice plate surface 2 are hexahedral plate surfaces with a width of 80 mm, a thickness of 1 mm, and a length A; The included angle between them is θ; two rows of orifice holes 3 with a radius of 5mm and a hole spacing of 40mm are distributed on the first side blowing orifice plate surface 1 and the second side blowing orifice plate surface 2, and the two rows of orifice plate openings The ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com