Two-stage compressor heat pump and oil return control system and method thereof

A two-stage compressor, oil return control technology, applied in compressors, heat pumps, refrigeration and liquefaction, etc., can solve the problem of uneven oil return of compressors, achieve uniform oil return, improve life, and prevent cylinder block wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

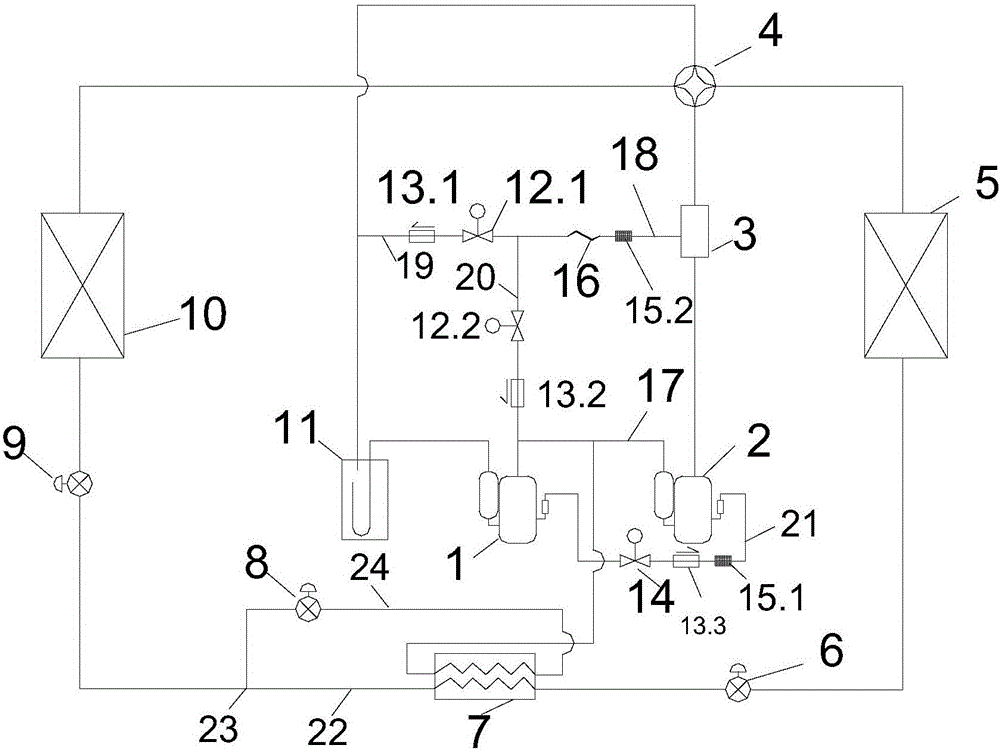

[0071] Such as figure 1 As shown, the present invention provides a two-stage compressor heat pump, which includes indoor and outdoor heat exchangers 5, 10, a low-pressure compressor 1 and a high-pressure compressor 2, and the exhaust port of the low-pressure compressor 1 passes through a medium-pressure pipe The road 17 communicates with the suction port of the high-pressure compressor 2, and an oil separator 3 is also connected to the exhaust end of the high-pressure compressor 2, and the oil separated by the oil separator 3 passes through the oil return pipe The road 18 is branched into two roads, one road is connected to the suction end of the low-pressure compressor 1 through the low-pressure oil return pipeline 19, and the other road is connected to the medium-pressure pipeline through the high-pressure oil return pipeline 20 and then connected to the high-pressure compressor 2 Suction end. (What needs to be explained here is: the low pressure, medium pressure and high p...

Embodiment 2

[0079] In this embodiment, on the basis of Embodiment 1, a first one-way valve 13.1 that only allows fluid to flow toward the suction port of the low-pressure compressor 1 is provided on the low-pressure oil return line 19;

[0080] And / or, a second one-way valve 13 .

[0081] By setting the above-mentioned first one-way valve on the low-pressure oil return line, the fluid (including oil and refrigerant) can only flow from the oil separator to the low-pressure compressor, effectively preventing the refrigerant or oil from flowing back from the low-pressure compressor , setting the above-mentioned second one-way valve on the high-pressure oil return pipeline can make the fluid (including oil and refrigerant) only flow from the oil separator to the low-pressure compressor, effectively preventing the refrigerant or oil from returning from the high-pressure compressor , Effectively guarantee the normal operation performance of high and low pressure compressors.

Embodiment 3

[0083] In this embodiment, on the basis of Embodiment 1 and / or 2, preferably, an oil equalizing pipeline 21 for equalizing oil between the low pressure compressor 1 and the high pressure compressor 2 is further provided in communication ,

[0084] And the oil equalizing pipeline 21 is also provided with an oil equalizing valve 14; and / or, the oil equalizing pipeline 21 is also provided with a third one-way valve that only allows fluid to flow from the low pressure compressor 1 to the high pressure compressor 2 Valve 13.3.

[0085] Through the structural form of an oil equalizing pipeline and an oil equalizing valve between the high and low pressure compressors, the oil can be distributed between the two compressors, especially the oil from the low pressure compressor can be lifted. The amount of oil entering the high-pressure compressor (because the amount of oil in the low-pressure compressor is usually greater than that in the high-pressure compressor), so that the oil cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com