Compressor liquid accumulator and inverter compressor

A compressor liquid storage and liquid storage technology, which is applied in the field of air-conditioning compressors, can solve problems such as reduction, and achieve the effects of improving reliability, improving gas transmission capacity, and improving possible insufficient oil return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the following specific embodiments will further describe the present invention in detail. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

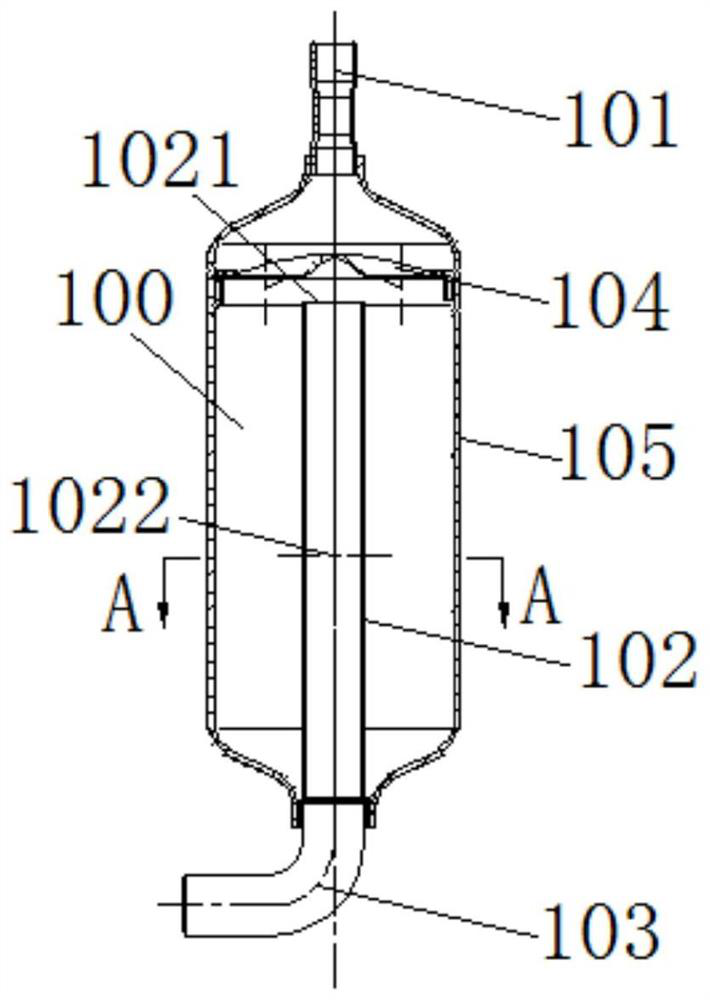

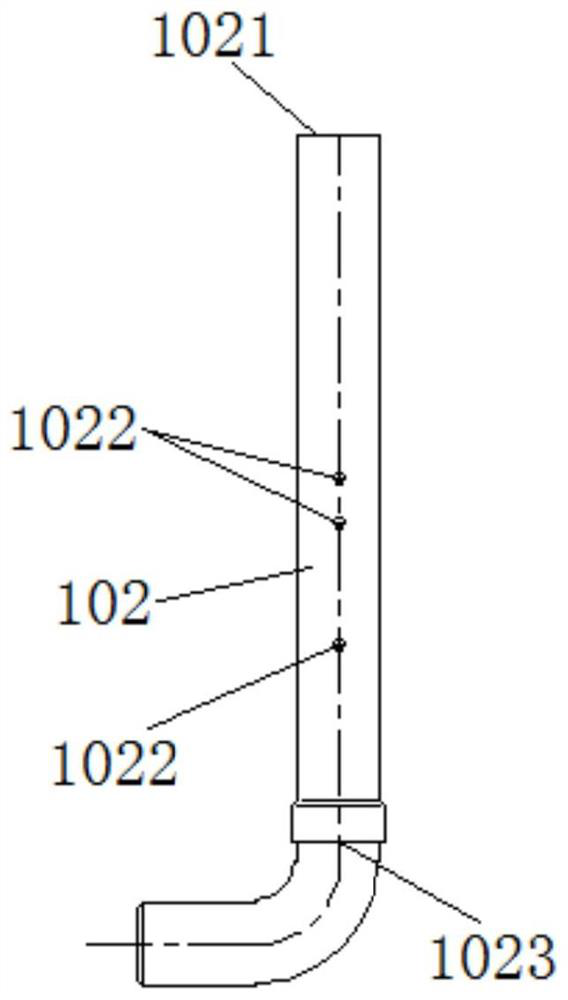

[0029] as attached Figure 1-4 As shown, the present invention provides a compressor accumulator, including an intake straight pipe 101, an exhaust straight pipe 102, an exhaust elbow 103, a filter screen assembly 104 and a liquid accumulator cylinder 105; the liquid accumulator cylinder The body 105 is an upper and lower open and airtight hollow cavity structure; the upper port of the accumulator cylinder is the inlet end, and the lower port is the outlet end; the filter screen assembly 104 is arranged in the accumulator cylinder 105, The filter screen assembly 104 divides the interior of the accumu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com