Coanda-effect-based air-conditioned plant roof air-film cooling apparatus

A technology of Coanda effect and cooling device is applied in the field of air-film cooling device on the roof of air-conditioning workshop, which can solve the problems of high cost, poor cooling effect, troublesome daily cleaning and maintenance, etc. The effect of request reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

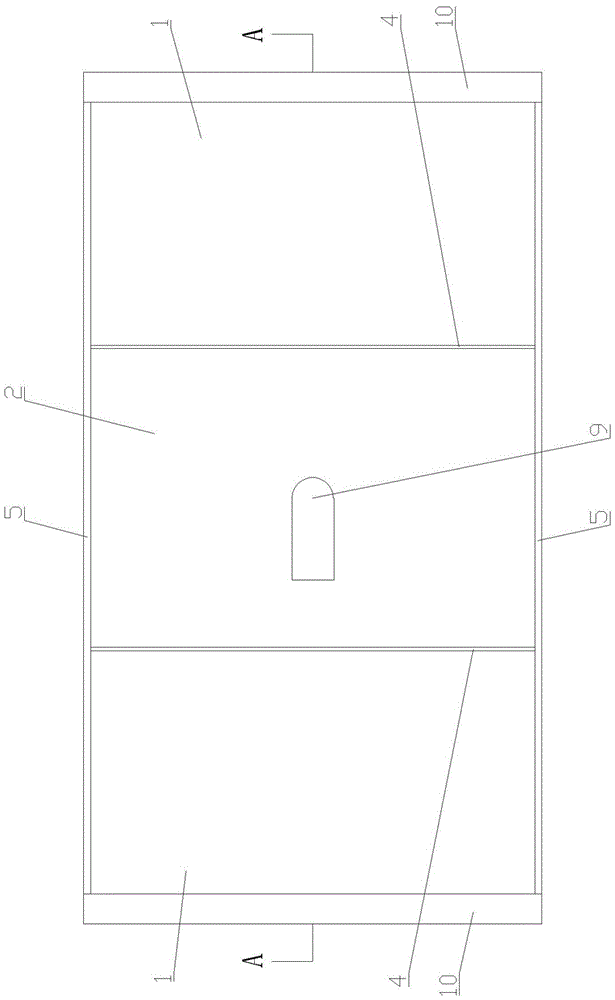

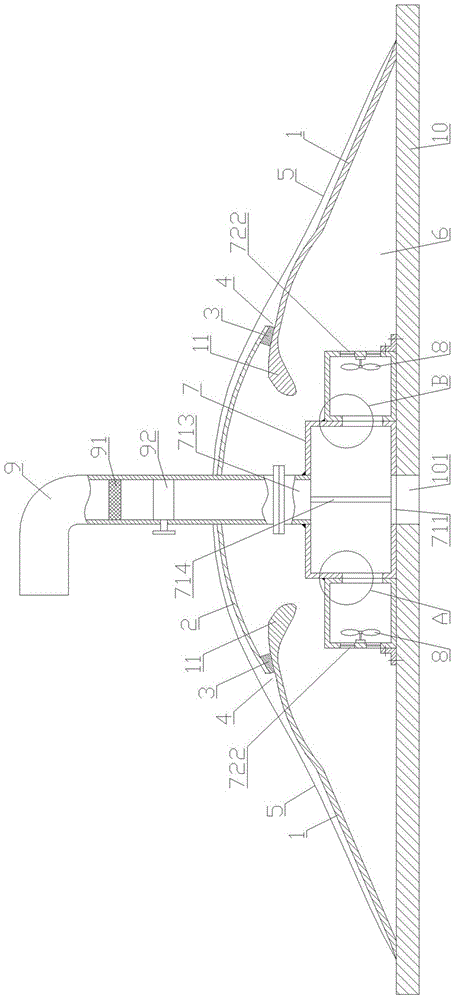

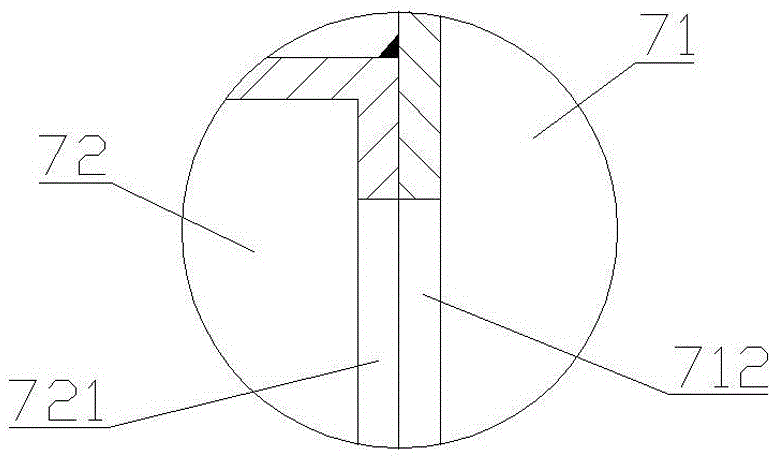

[0038] Such as Figure 1-4 As shown, the air-film cooling device on the roof of an air-conditioning factory based on the Coanda effect includes a Coanda airfoil 1, an arc-shaped upper cover 2, a connecting block 3, an end plate 5, an air box 7, an exhaust fan 8, a fresh air pipe 9 and Bottom plate 10 .

[0039] The Coanda airfoil 1 is located above the bottom plate 10 and below the side of the arc-shaped upper cover 2 , and an arc-shaped diversion head 11 is provided at one end thereof. The smooth curved surface of the arc-shaped flow guide head 11 can reduce turbulent flow noise caused by the airflow encountering sharp objects. There are two Coanda airfoils 1 , which are respectively located under the two sides of the arc-shaped upper cover 2 . The outer surface of the Coanda airfoil 1 is a Coanda curved surface.

[0040] The arc-shaped upper cover 2 is arranged on the upper end of the Coanda airfoil 1, and it is connected to the arc-shaped guide head 11 of the Coanda airf...

Embodiment 2

[0050] Such as Figure 6-7 As shown, the only difference between this embodiment and embodiment 1 is that the number of Coanda airfoil 1 is one. There are four end plates 5 , two of which are connected to both sides of the Coanda airfoil 1 and the arc-shaped upper cover 2 , and the other two are connected to the arc-shaped upper cover 2 . The static pressure chamber 71 is only provided with an air outlet A712 on one side wall.

[0051] Briefly describe the use of the present invention: as Figure 5 , 8 As shown, before use, the hole 991 connected to the room needs to be opened in advance on the roof 99 of the factory building. During use, the present invention is placed on the roof 99 of the factory building. The exhaust fan 8, the cold air in the room enters the static pressure chamber 71 through the hole 991 on the roof 99 of the factory building, the air hole 101 on the bottom plate 10 and the air inlet A711 of the static pressure chamber 71, and then passes through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com