Combustion system of a fanless alcohol-based fuel cooker

An alcohol-based fuel and combustion system technology, applied in the field of stoves, can solve problems such as waste of fuel, carbon deposits in the stove, and small flames, and achieve the effects of ensuring personal safety, prolonging service life, and helping combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

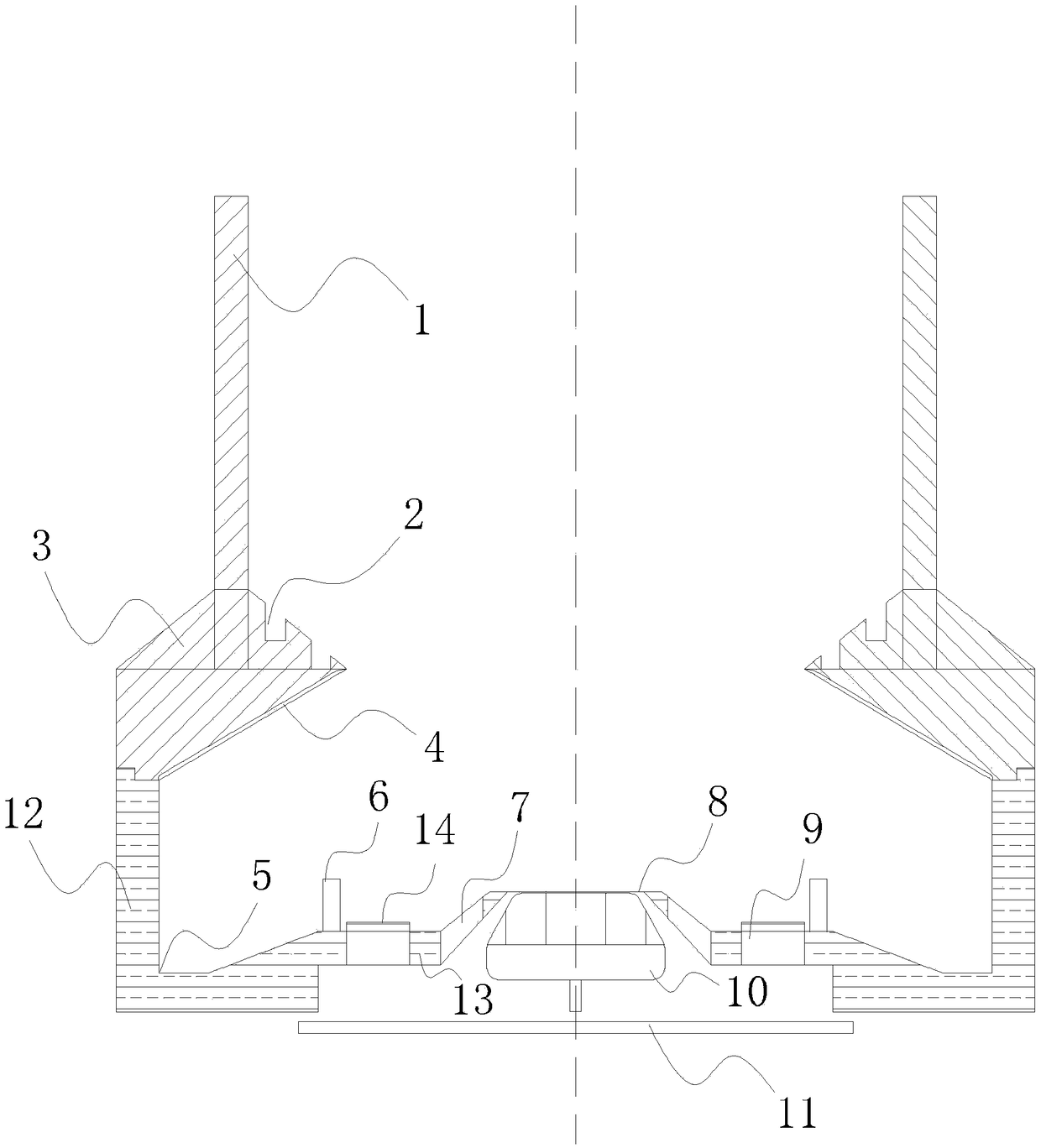

[0026] Such as figure 1 The combustion system of a fanless alcohol-based fuel cooker shown includes: a base 12, which is a cavity with an upward opening. In this embodiment, the base 12 is annular or circular, and the inside of the base 12 is provided with a backflow The groove 5 and the return groove 5 are annular grooves, the bottom surface of the base 12 is provided with an oil injection port 8, and a ventilator 13 is arranged between the oil ejection port 8 and the return groove 5, and the ventilator 13 is also annular, and its inner side is higher , the outer side is lower and protruding, the ventilator 13 is provided with the main air inlet 9, and the spray nozzle 10 is arranged below the fuel injection port 8, and the air enters the fuel injection port 8 below the main air inlet 9 to provide oxygen for combustion.

[0027] The upper end of the base 12 is provided with an air intake lock 3, and the upper end of the air intake lock 3 is provided with an opening mask 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com