Complete top air inlet type kitchen range combustor and kitchen range

A technology for burners and stoves, which is applied to burners, gas fuel burners, combustion methods, etc., can solve the problems of insufficient primary air, large volume of the bottom shell, insufficient combustion, etc., and achieves reduced height, high energy efficiency ratio, and air sufficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

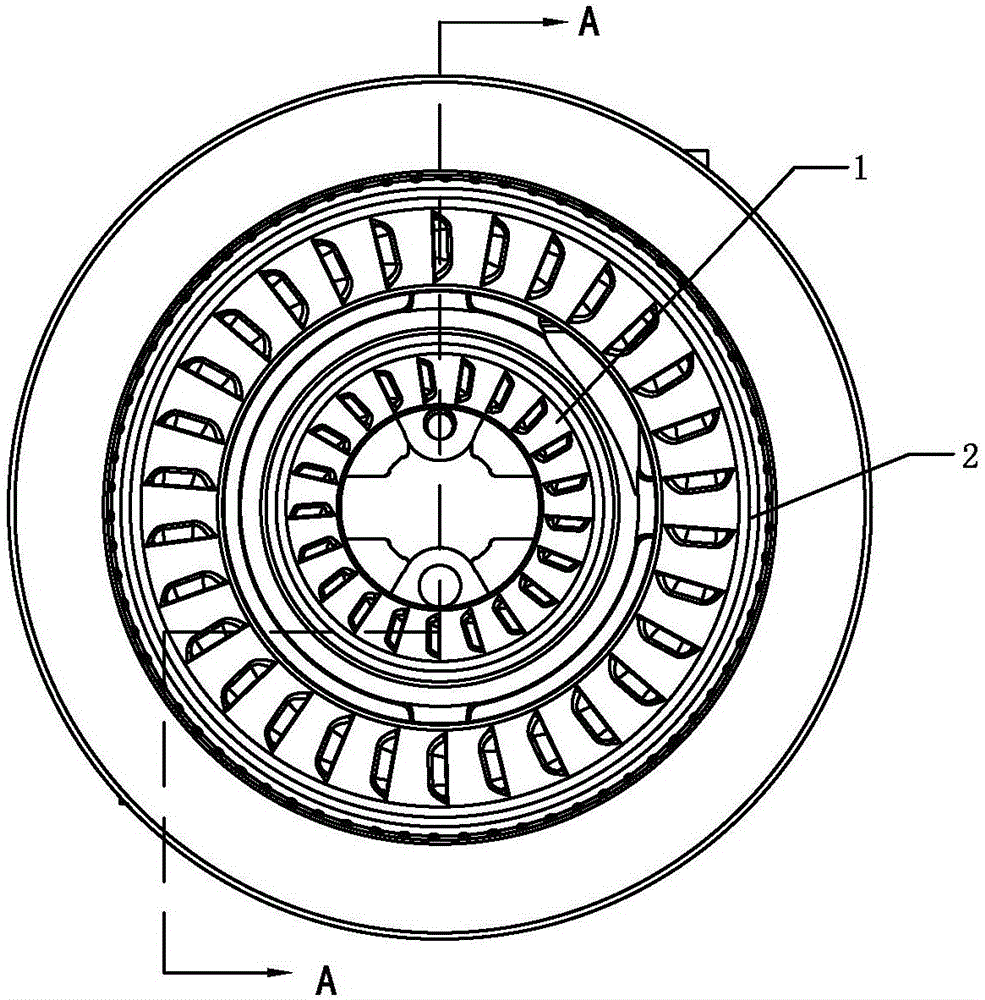

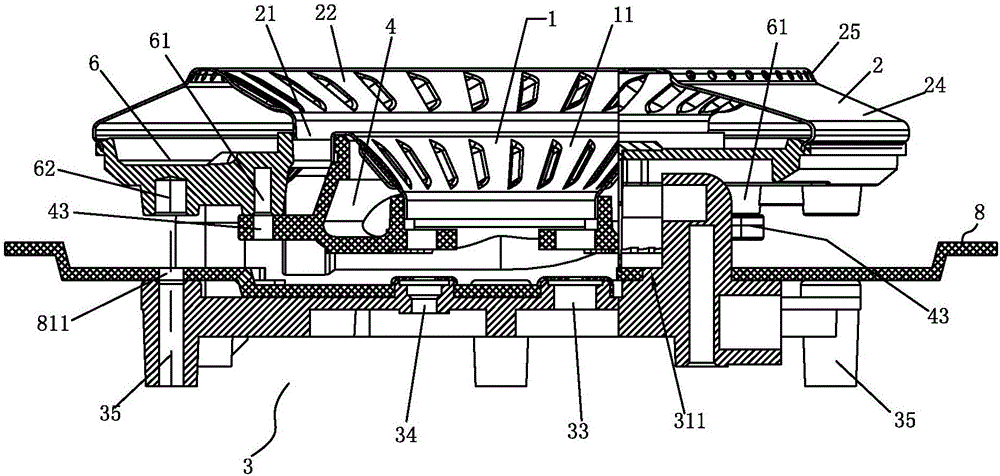

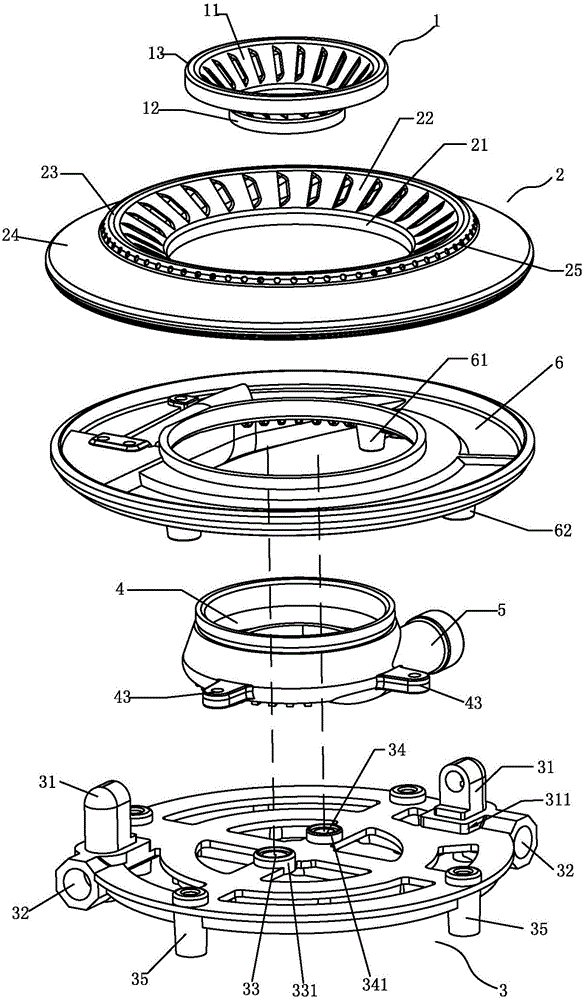

[0041] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a full upper air inlet type cooker burner includes an inner fire cover 1 and an outer fire cover 2, and also includes a seat frame 3, an inner ring gas mixing tank 4, an inner injection pipe 5, an outer ring gas mixing tank 6 and Outer injection tube 7,

[0042] Two air outlet heads 31 are arranged on the upper surface of the seat frame 3, and the axes of the air outlet holes of the two air outlet heads 31 are parallel to the horizontal plane; two air inlet heads 32 communicate with the air outlet head; an ignition pinhole 33 and The hot water couple hole 34 is arranged on the lower surface and is circularly and evenly distributed supporting connecting columns 35, the supporting connecting columns 35 extend to the upper surface, and the supporting connecting columns 35 have connecting holes along the axis;

[0043] The inner injection pipe 5 communicates with the inner ring gas mixing tank 4; in the cente...

Embodiment 2

[0056] Such as figure 2As shown, a gas cooker includes a burner, a water tray 8 and a cooker bottom case (not shown in the figure), and the burner includes an inner fire cover 1, an outer fire cover 2, a seat frame 3, an inner Ring gas mixing tank 4, inner injection tube 5, outer ring gas mixing tank 6, injection tube 7 and support column;

[0057] The water receiving tray 8 includes an upper opening disc body 81 and an outer edge 82. The center of the disc body 82 has an upper opening cavity 83. The disc body 81 is provided with uniform connection holes 811 and air outlet holes 812. The base plate is provided with an ignition pinhole 331 and a thermocouple hole 832;

[0058] The lower end of the supporting connecting column 35 is fixedly connected with the bottom plate of the cooker bottom shell, the gas outlet head 31 protrudes through the gas outlet hole 812 on the disc body 81, and the upper end of the supporting connecting column 35 supports the disc body 81; Seat 33, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com