Double-head impact absorption device

A shock absorbing, double-headed technology, applied in the field of vibration energy absorbing devices, can solve problems such as inability to provide return force, achieve stable and reliable working process, realize the return of both ends, and achieve the effect of averaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

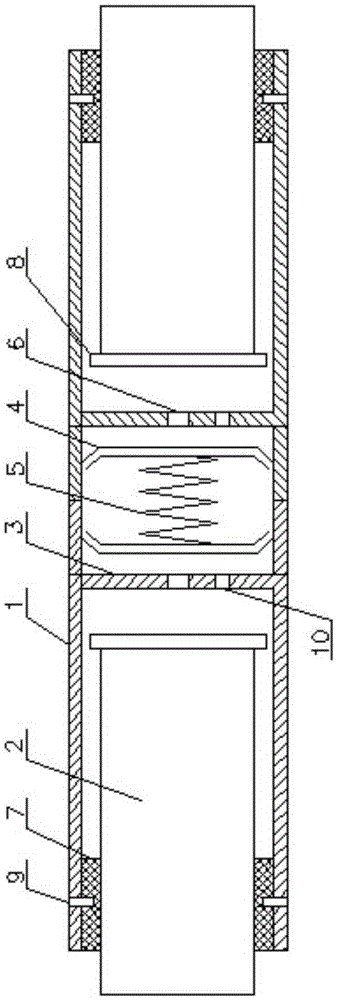

[0029] Such as figure 1 As shown, the double-head shock absorbing device includes an outer cylinder 1, a compression column 2, a damping plate 3, a floating piston 4 and a spring 5; Symmetrically arranged in the outer cylinder 1, two floating pistons 4 are arranged oppositely between the two damping plates 3, and the two floating pistons 4 are connected by a spring 5; two compression columns 2 are respectively inserted through the two ends of the outer cylinder 1 Inside the outer cylinder 1 ; damping holes 6 are opened on the damping plate 3 . A one-way valve 10 leading to the end of the outer cylinder 1 is arranged on the damping plate 3 .

[0030] It works as follows:

[0031] Inside the outer cylinder 1, the space between the end of the compression column 2 and the damping plate 3 is filled with oil. When an external force is applied, the compression columns 2 at both ends move toward the center of the outer cylinder 1 at the same time, compressing the oil to make the oi...

Embodiment 2

[0035] Such as figure 1 As shown, this embodiment is based on Embodiment 1, and a sealing support body 7 is arranged between the outer cylinder body 1 and the compression column 2 .

[0036] A sealing support member 7 is provided to avoid oil leakage in the outer cylinder.

Embodiment 3

[0038] Such as figure 1 As shown, this embodiment is based on Embodiment 2, and the outer circular surface of one end of the compression column 2 inside the outer cylinder body 1 is provided with a retaining ring 8 .

[0039] A retaining ring 8 is provided to prevent the compression column 2 from detaching from the outer cylinder 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com