Automobile exhaust gas emission system with damping device

A technology for shock absorption device and automobile exhaust, which is applied in muffler device, exhaust device, exhaust treatment and other directions, can solve problems such as damage to the environment and air pollution, and achieve the effects of improved filtering effect, low processing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

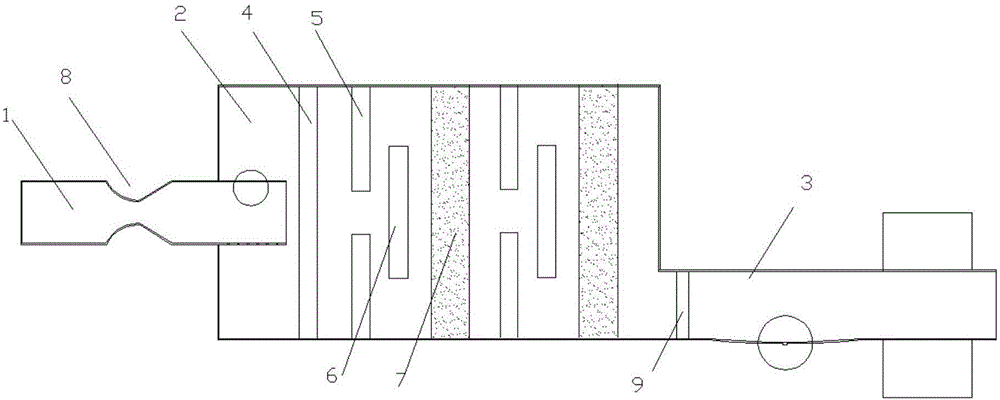

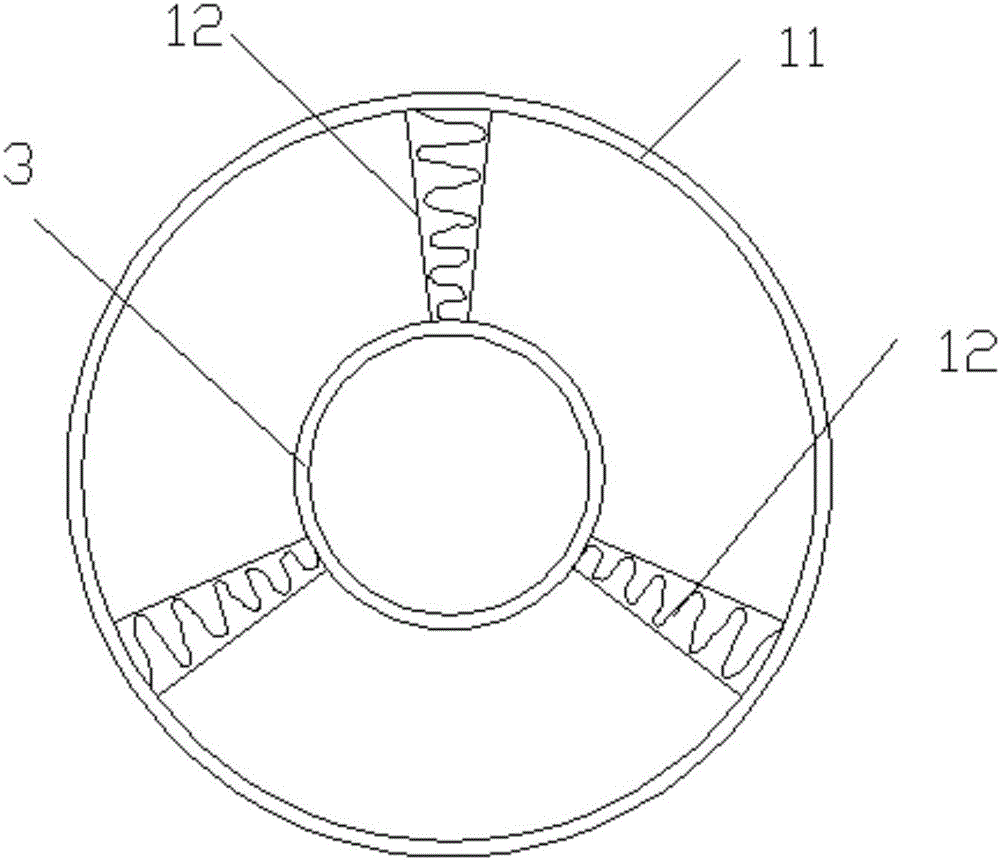

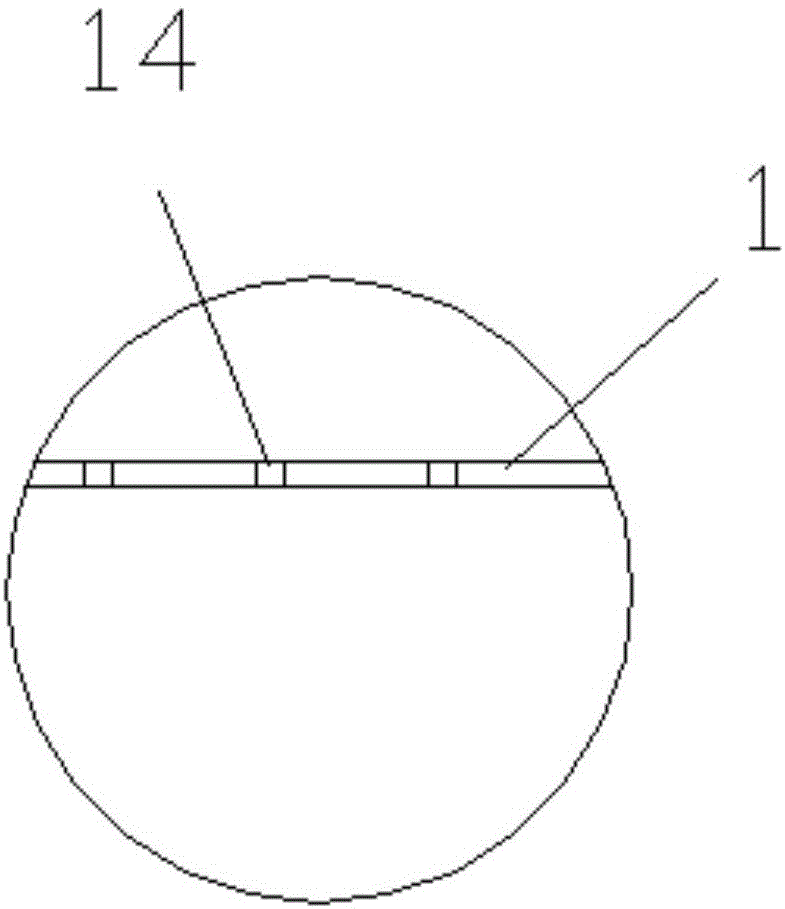

[0023] Such as Figure 1-4 As shown, a vehicle exhaust emission system with a shock absorber includes an air intake pipe 1, an intermediate pipe body 2, and an air outlet pipe 3. The air intake pipe 1 is connected to the air outlet pipe 3 through the intermediate pipe body 2, and the air outlet pipe 3 External shock absorber,

[0024] The air inlet pipe 1 extends into the middle pipe body 2, and a part of the side wall extending into the middle pipe body 2 is provided with air outlet holes, and the right side of the air inlet pipe 1 is provided with some filtering devices located in the middle pipe body 2, the said The filtering device includes a primary filter element 4, a first flow equalization barrier 5 which is vertically symmetrical is provided on the right side of the primary filter element 4, and a second current equalization barrier 6 located in the middle is arranged on the right side of the first current equalization barrier 5 , the right side of the second flow eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com