Dust removal system based on mine cooling system

A dust removal system and mine technology, which is applied in the ventilation, dust prevention, mining equipment and other directions of mines/tunnels, can solve the problems of large power consumption, high operating costs, and high investment costs, save water for dust reduction, improve dust reduction effects, Guaranteed cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

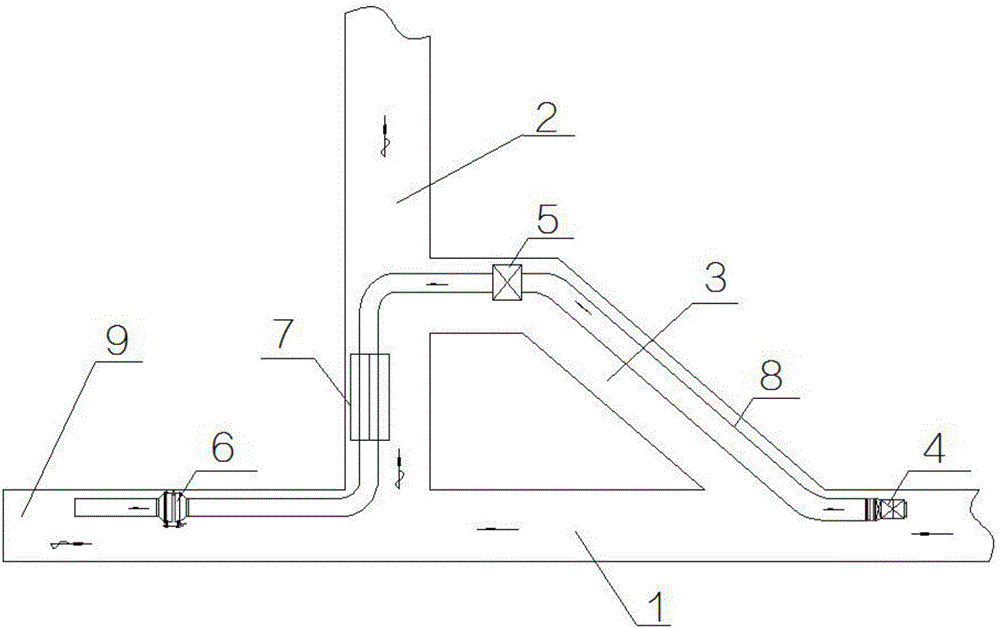

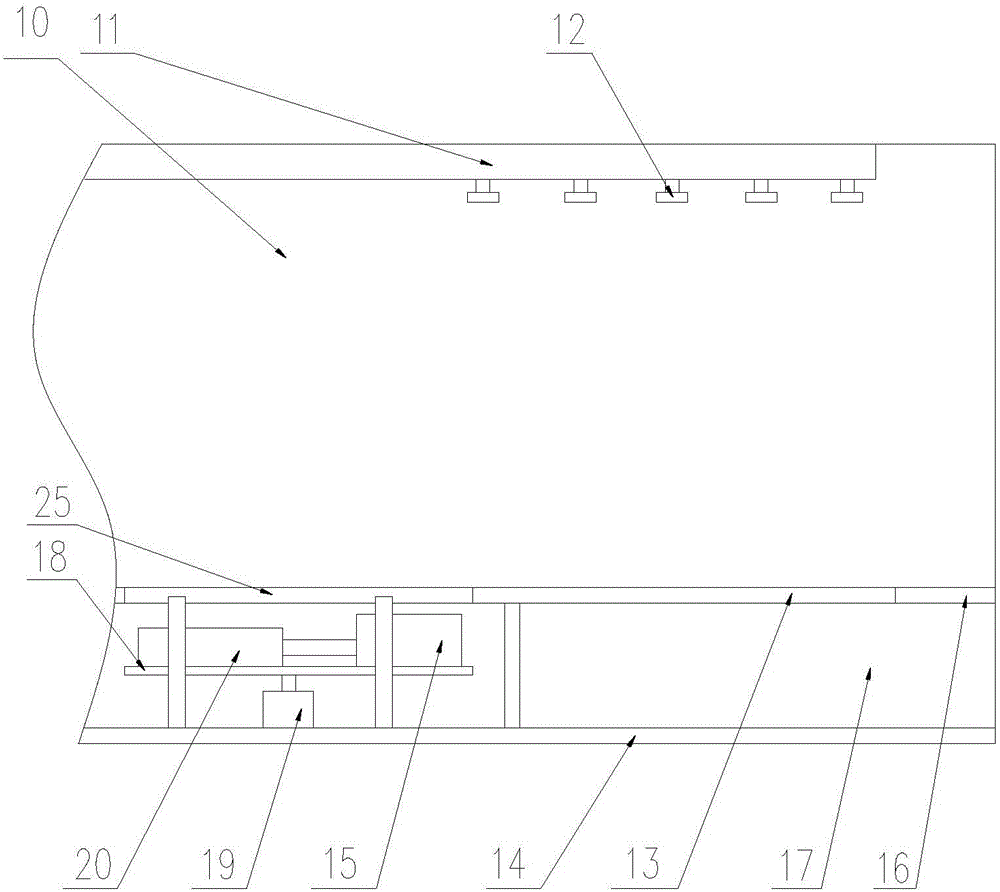

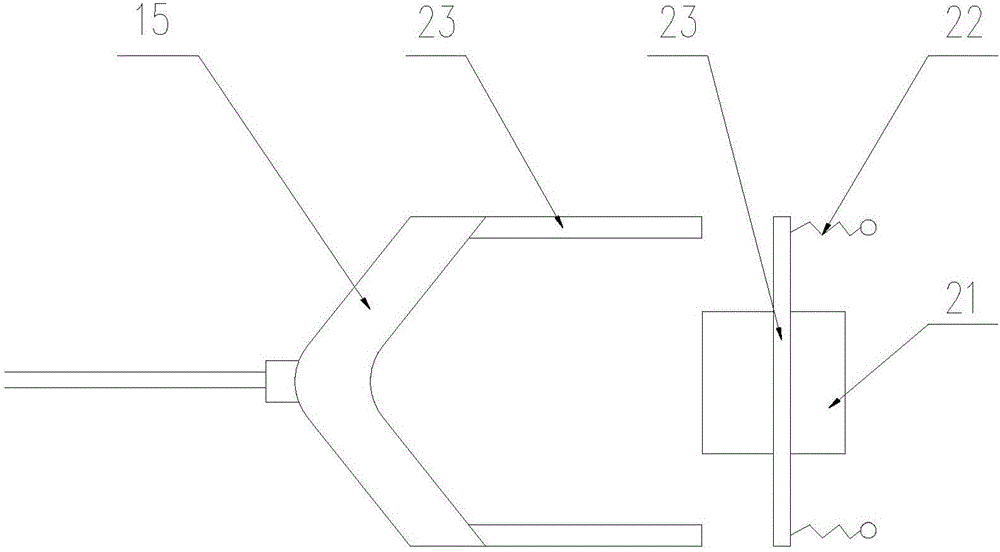

[0027] see Figure 1 to Figure 3 , is a preferred embodiment of the dust removal system based on the mine cooling system, including the tunneling tunnel 1 of the mine, the return tunnel 2 and the dehumidifier chamber 3, and one end of the tunneling tunnel 1 is the air inlet of the tunneling tunnel 1 The other end is the working site 9, the first air outlet and the second air outlet are opened on the tunneling roadway 1, the return air tunnel 2 is perpendicular to the tunneling tunnel 1, and the first air inlet is set at one end of the return air tunnel 2 , the first air inlet communicates with the first air outlet of the tunneling roadway 1, the other end of the air return roadway 2 is the air outlet end of the air return roadway 2, and a second air inlet is opened on the air return roadway 2, and the dehumidifier The air inlet end of the chamber 3 communicates with the second air outlet of the tunneling roadway 1, and the air outlet end of the dehumidifier chamber 3 communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com