Full-section jacking system and jacking method for underground excavation of comprehensive pipe gallery sub-storage structure

A comprehensive pipe gallery and full-section technology, which is applied in the direction of earthwork drilling, mining equipment, tunnels, etc., can solve the problems of complex construction of the integrated pipe gallery sub-warehouse structure, and achieve the effects of small resistance, reduced engineering cost, and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings.

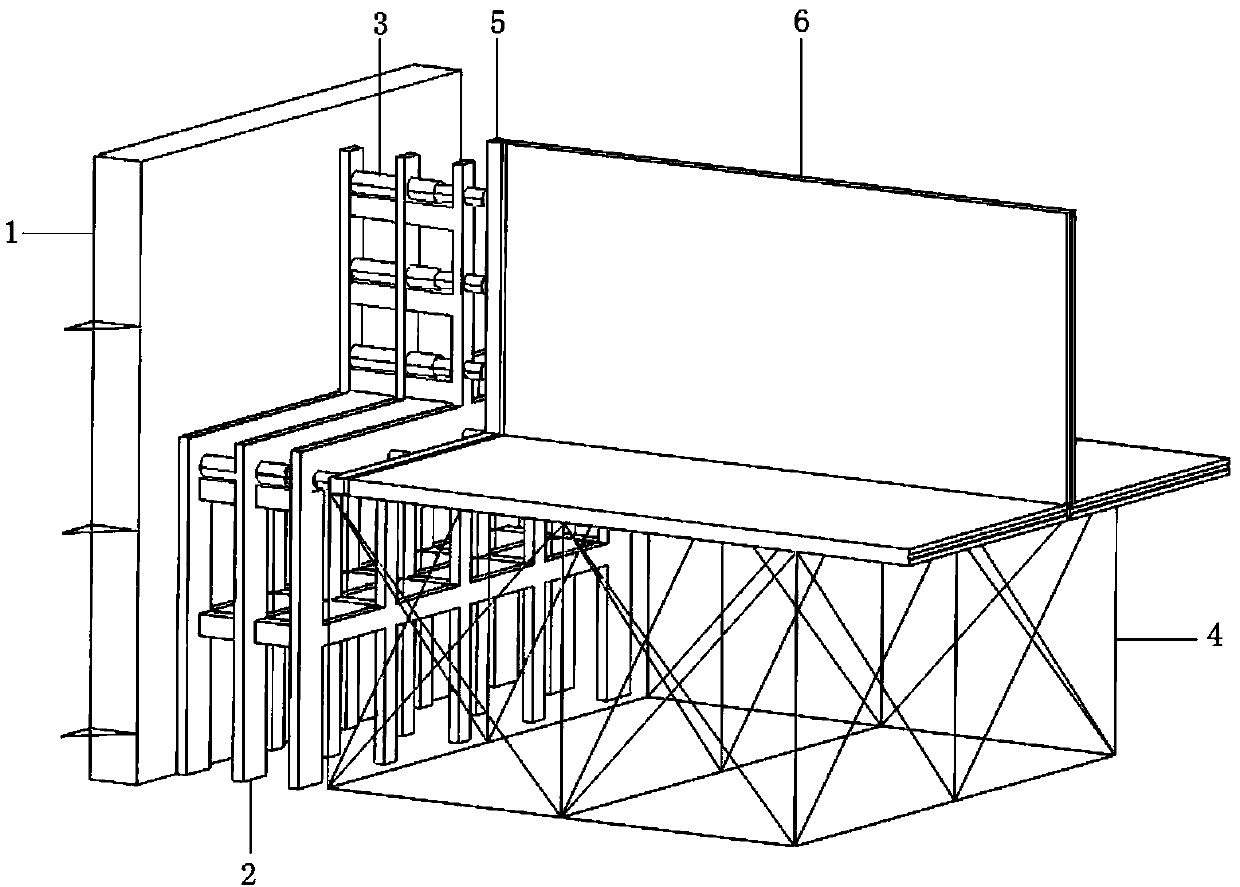

[0041] as attached Figure 1 to Figure 8 As shown, a full-section jacking system for the sub-compartment structure of the integrated pipe gallery in the underground excavation, including a drag reduction system installed in the pipe gallery on the small longitudinal beam 7 for bearing the gravity of the inverted T sub-compartment structure 6 8, and the jacking system body set in the node well of the pipe gallery.

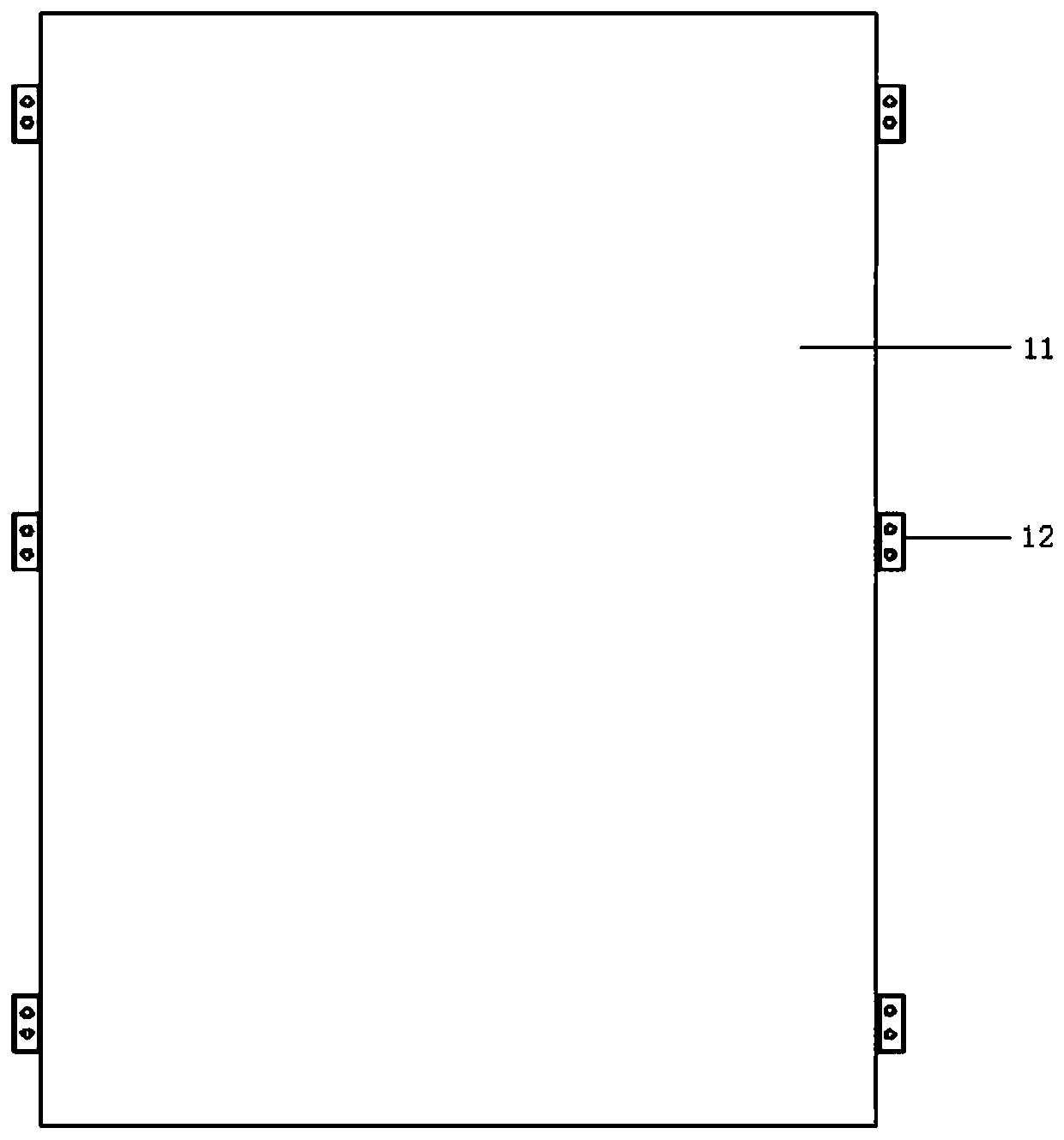

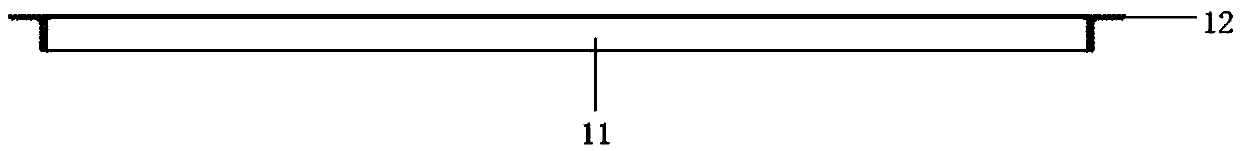

[0042] The push system body includes a reaction back system 1 , a support frame 2 for the push system, a push system 3 , a guide rail 4 and an inverted T-beam 5 for force transmission. The reaction force back system 1 is arranged between the side walls of the node well jacking in the opposite direction, including a steel plate box 11 with a width greater than the cross section of the pipe gallery, and is arranged on both sides of the steel plate box 11 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com