A construction method for shield tunneling in composite strata

A technology of composite stratum and construction method, which is applied in the direction of earthwork drilling, mining equipment, tunnels, etc., can solve the problems that affect the heat generation, wear, cutting efficiency and reliability of cutterhead tools, increase the difficulty of cutterhead design, etc., and achieve easy promotion Ease of use, realization and operation, and the effect of preventing partial wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

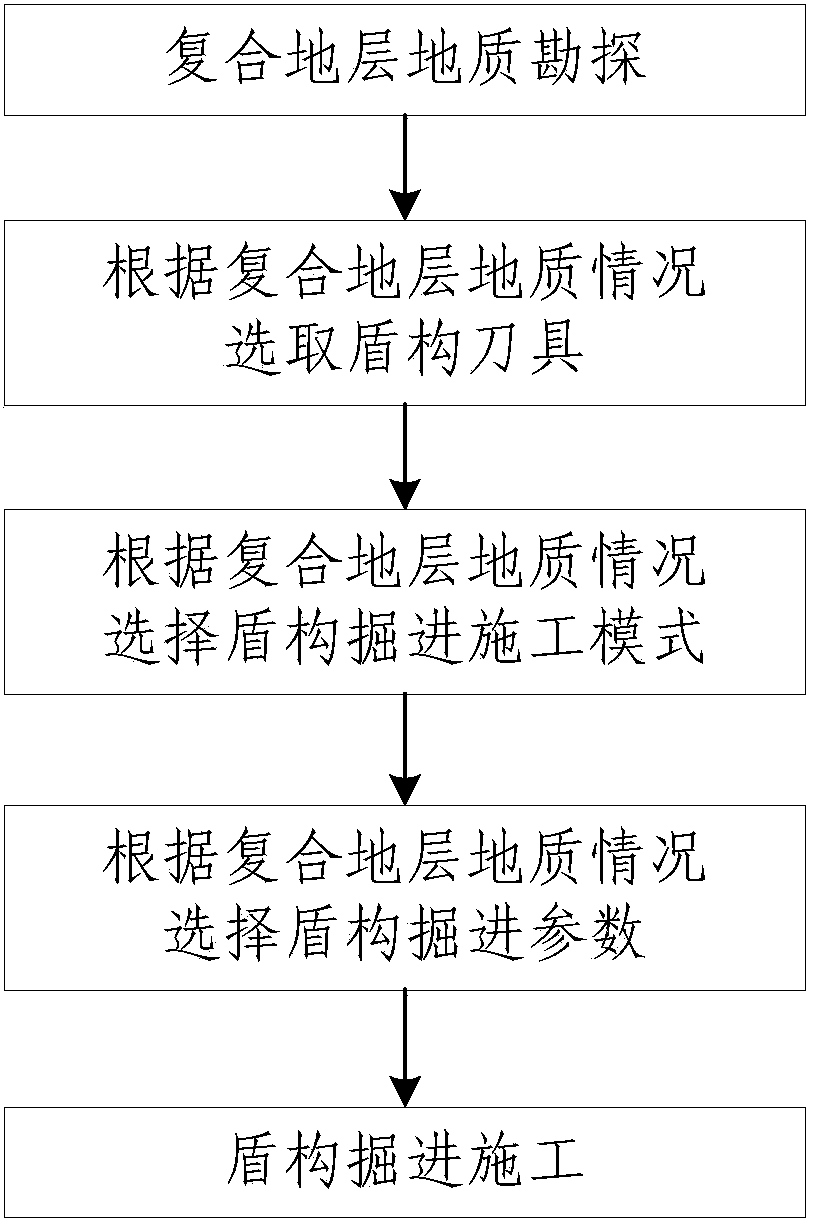

[0033] Such as figure 1 Shown, the present invention comprises the following steps:

[0034] Step 1. Geological exploration of the compound stratum: by drilling holes on the compound stratum, the geological conditions of the compound stratum are ascertained;

[0035] Step 2. Select the shield cutting tool according to the geological conditions of the compound stratum, including the following steps:

[0036] Step 201, analysis of the force of the shield cutter:

[0037] Step 201, layout of shield cutters: install different cutters according to the geological conditions of the compound stratum, and the distance between the cutters in Indicates the rock breaking angle of the composite formation, T indicates the width between two adjacent hob tips, H indicates the penetration of the hob, and the cutters are arranged on the cutter head according to the tool tip distance S;

[0038] Step 202, calculate the pressure P of a single hob in the crushing zone, Among them, C repres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com