A special threaded joint for oil well pipe

A special thread and threaded joint technology, used in drill pipes, casings, drilling equipment, etc., can solve problems such as leakage and poor torque resistance, and achieve the effects of large sealing area, improved torque resistance, and improved sealing ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to more clearly illustrate the technical solutions in the embodiments of the present invention or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. Those skilled in the art can also obtain other drawings based on these drawings without creative work.

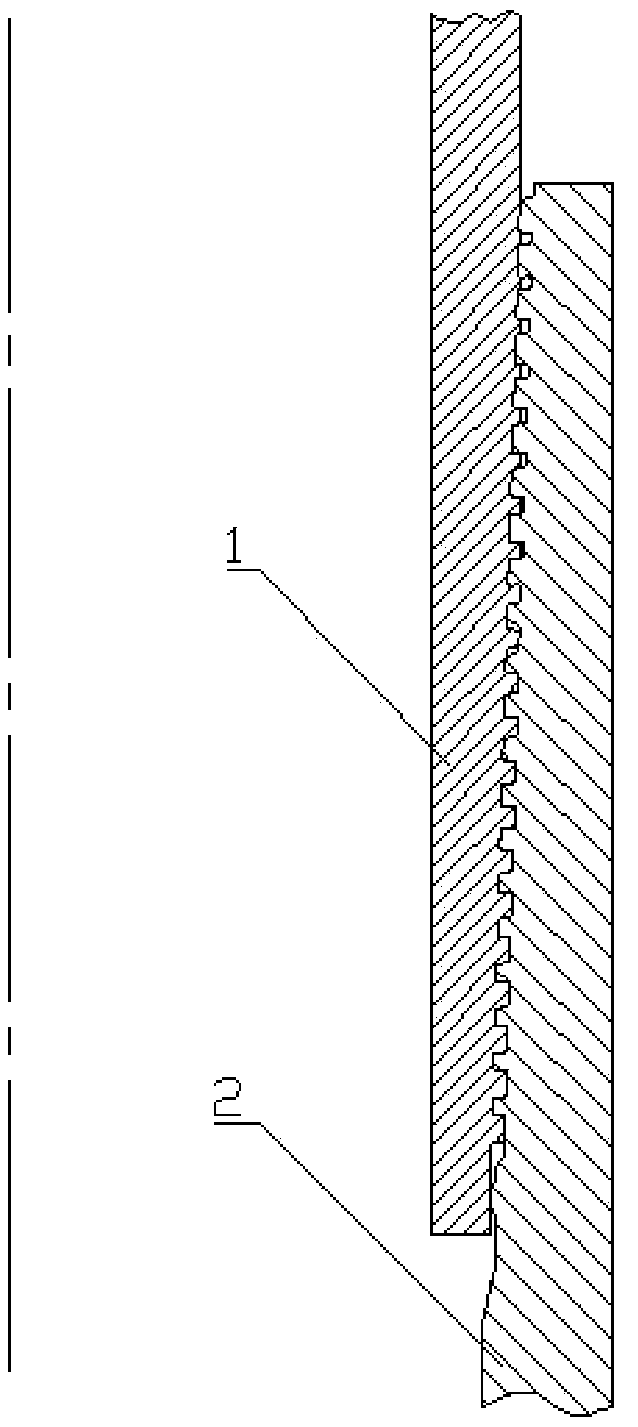

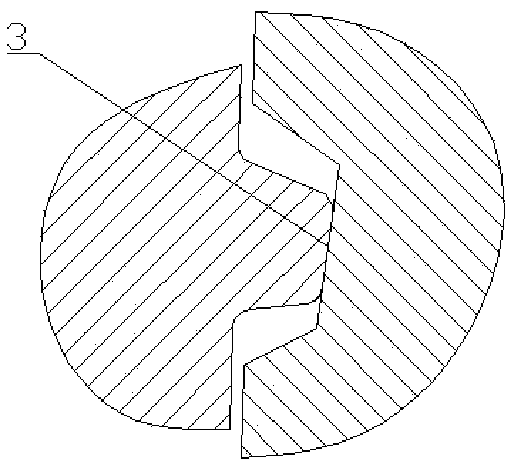

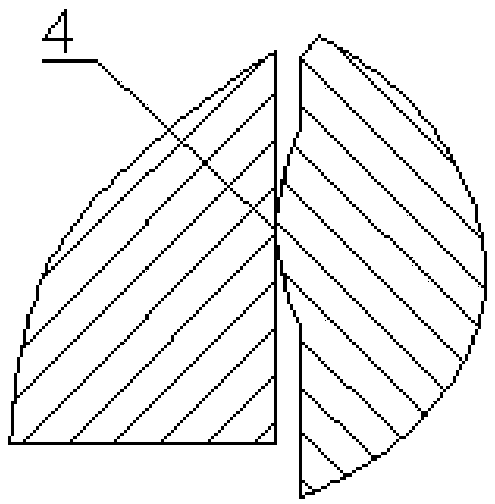

[0026] Such as Figure 1-5 As shown, the oil well pipe special threaded joint of the present invention includes an externally threaded joint 1 and an internally threaded joint 2 assembled together. The threads of the externally threaded joint 1 and the internally threaded joint 2 are hook-shaped variable tooth wide threads. The seal consists of double seals, the double seals include a set of cone / cone seals 3 and a set of cylindrical / spherical seals 4, the special threaded joint has no shoulder; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com