Large-capacity constant-tension warp letting-off system and yarn distributing method thereof

A technology with constant tension and large capacity, which is applied in textiles, textiles, papermaking, and looms. It can solve the problems of continuous warp feeding, yarn-yarn entanglement and wear, and poor clarity of warp yarn arrangement. Thread abrasion, uniform single yarn tension control, and clear yarn arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

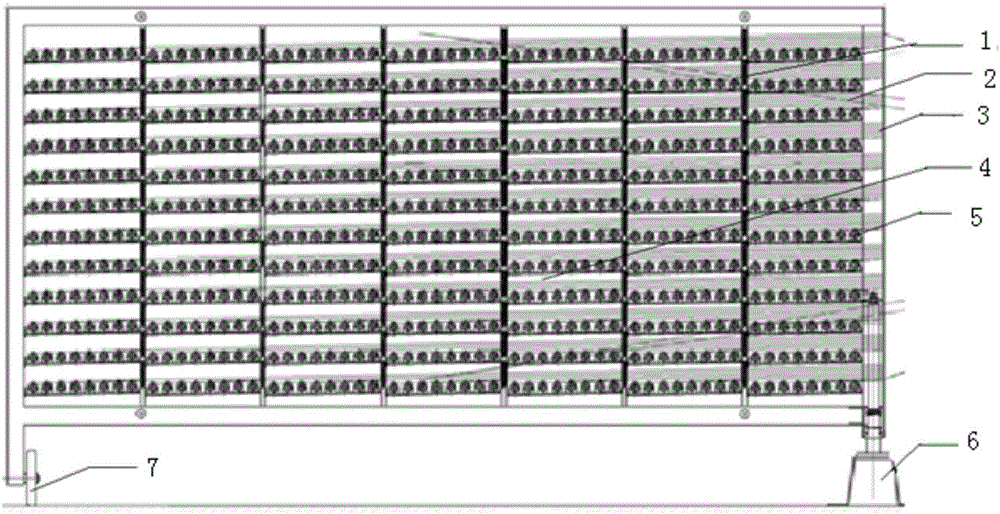

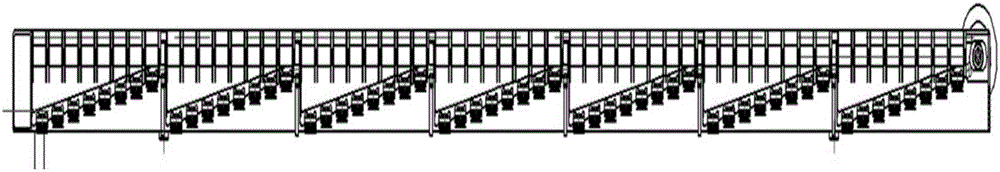

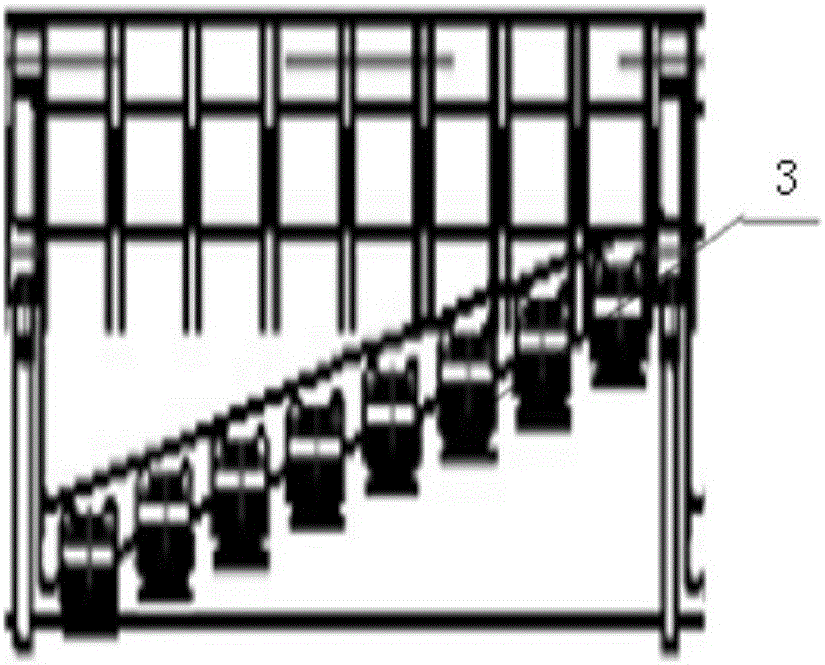

[0056] Example 1: Taking the glass fiber panel fabric as an example: the number of warp layers of the preform is 12, the fabric width is 300mm, the warp density of the fabric is 5 threads / cm, the warp specification is 480Tex×1 strand, and the fabric structure is three-dimensionally woven with shallow bends Even fiber layered structure. According to the technical parameter requirements of the panel fabric, the fabric width is 300mm and the fabric warp yarn density is 5 threads / cm, it can be calculated that the required number of warp yarn columns is 300×0.5=150 columns, and the number of warp yarn layers is designed to be 12 layers. The panel fabric needs a total of warp yarns Capacity 12 floors × 150 columns = 1800 pieces.

[0057] According to the design requirements of process parameters, each piece creel realizes the storage and tension control of N (12 layers) × M (56) columns = G (672) warp yarns. Large-capacity constant tension warp let-off system composed of pieced cre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com