Felt jacket tensioning system of decating machine

A felt cover and tensioning technology, applied in the control/adjustment system, textile processing machine accessories, textile material processing and other directions, can solve the problems of increasing the cost of steaming and shortening the life of the felt cover, and achieves improved life and balanced tension control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with specific drawings and embodiments.

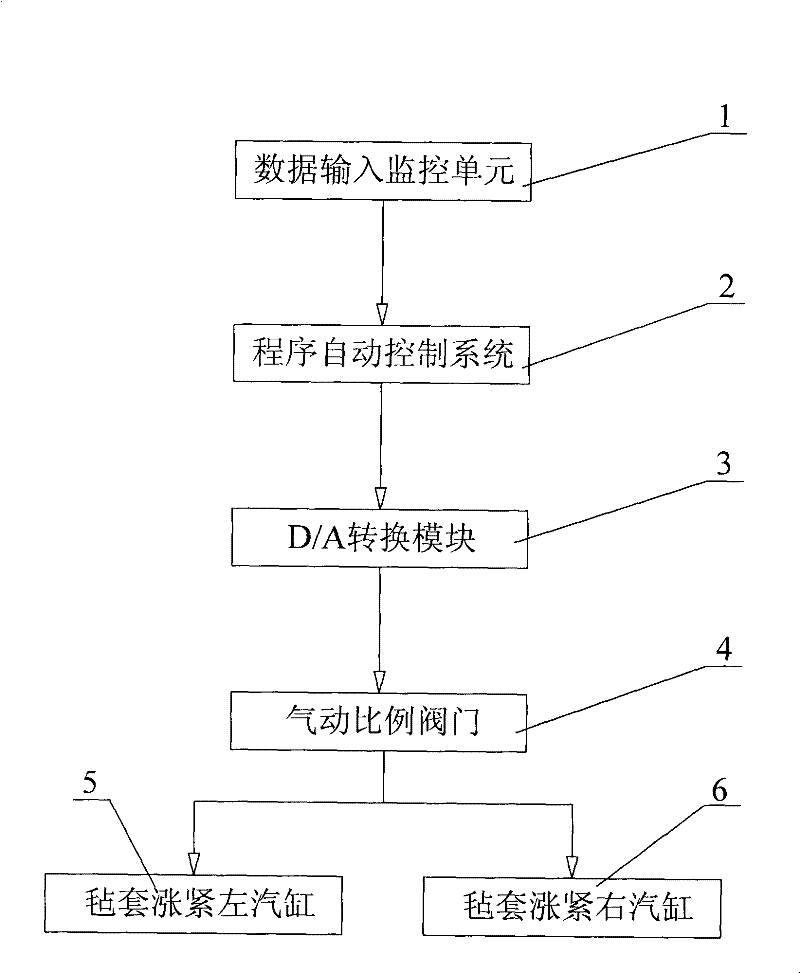

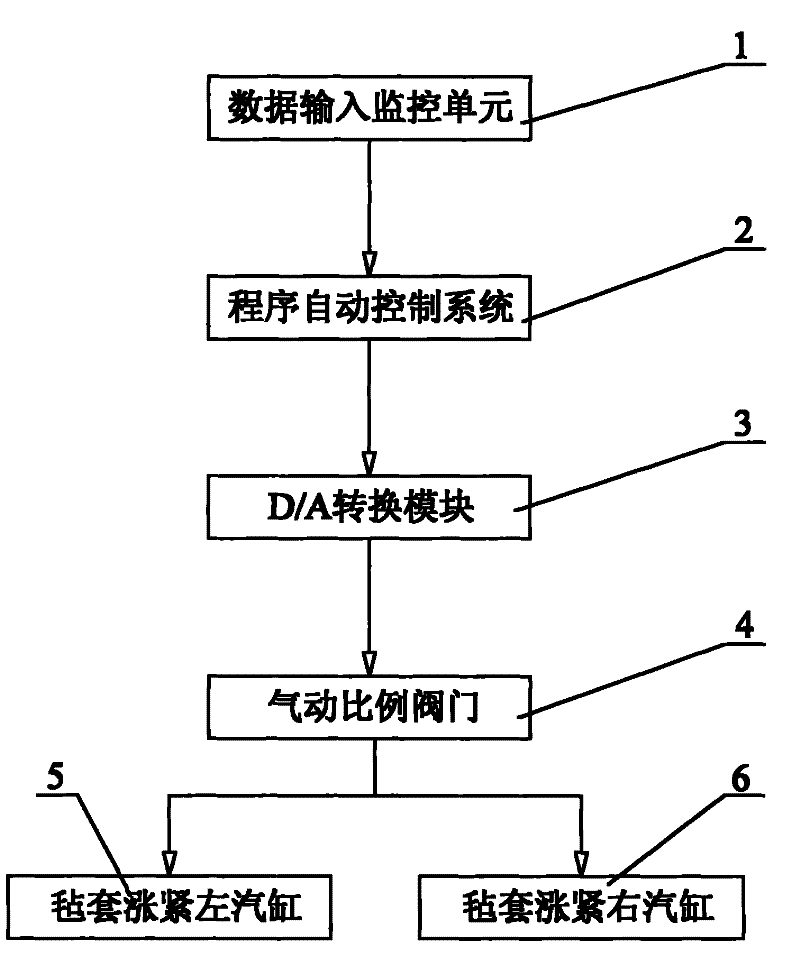

[0009] As shown in the figure: the felt sleeve tensioning system of the desiccating machine, which includes data input monitoring unit 1, program automatic control system 2, D / A conversion module 3, pneumatic proportional valve 4, felt sleeve tensioning left cylinder 5 and The felt sleeve tensioning right cylinder 6, the output terminal of the data input monitoring unit 1 is connected to the input terminal of the program automatic control system 2, the output terminal of the program automatic control system 2 is connected to the input terminal of the D / A conversion module 3, and the D / A conversion module The output terminal of 3 is connected to the input terminal of the pneumatic proportional valve 4, one output terminal of the pneumatic proportional valve 4 is connected to the input terminal of the felt sleeve tensioning left cylinder 5, and the other output te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com